Aircraft anticorrosion oil cleaning agent

A cleaning agent and anti-corrosion oil technology, applied in the chemical industry, can solve the problems of slow volatilization rate, increase operating time, affect the scope of application, etc., and achieve the effects of convenient storage and transportation, improved cleaning ability, and reasonable and scientific collocation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

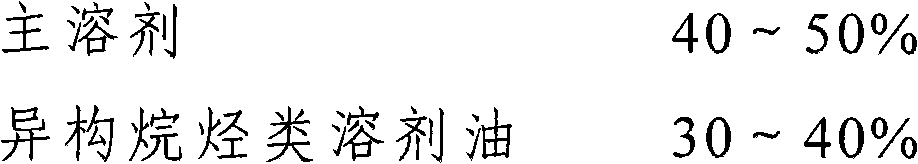

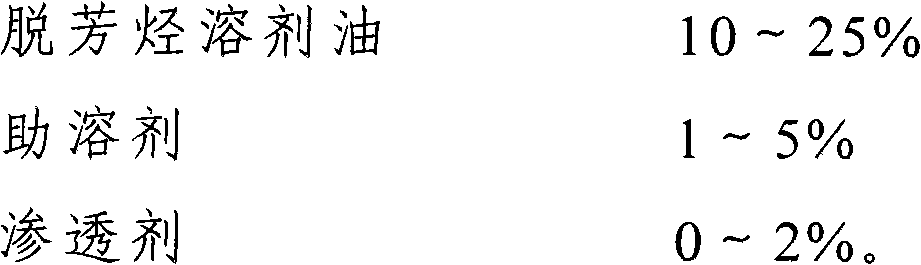

Method used

Image

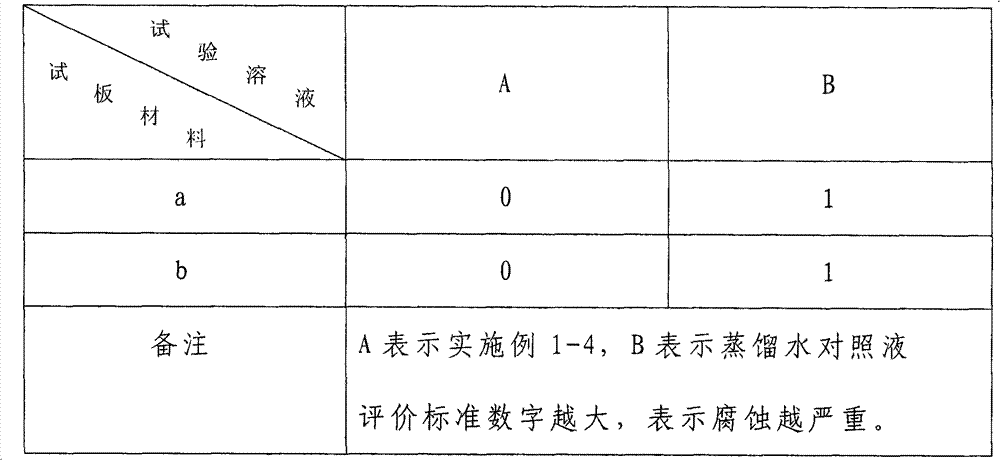

Examples

Embodiment 1

[0031] Tetrachlorethylene: 40%

[0032] Isoparaffin spirit: 35%

[0033] Dearomatized mineral spirits: 20%

[0034] Ethanol: 3%

[0035] JFC: 2%.

Embodiment 2

[0037] Tetrachlorethylene: 40%

[0038] Isoparaffin solvent oil: 30%

[0039] Dearomatized mineral spirits: 25%

[0040] Isopropanol: 3%

[0041] Isogenic Tridecyl Ethoxylates: 2%.

Embodiment 3

[0043] Dichloromethane: 40%

[0044] Isoparaffin solvent oil: 30%

[0045] Dearomatized mineral spirits: 25%

[0046] Isopropanol: 3%

[0047] OEP-70: 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com