Multilayer heat insulation barrel device and production method thereof

A technology of multi-layer heat insulation and manufacturing method, which is applied in the preparation of heat-insulation cylinders and the field of multi-layer heat-insulation cylinder devices, which can solve the problems of hollow cylinders such as easy damage, rising use costs, and general heat preservation effects, and achieve cost reduction , prolong the service life, accelerate the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

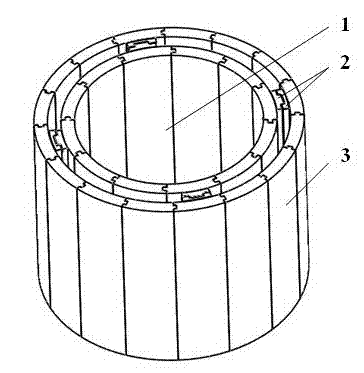

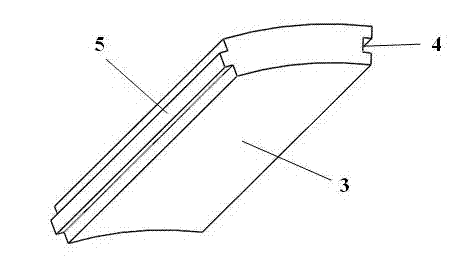

[0027] The first step is to prepare the slat unit and the sliding member: according to the required size, determine the size and radian of the multi-layer insulation tube slat unit 3 and the sliding member 2; design and prepare the slat unit 3 and the sliding member according to the determined size and radian The corresponding mold of component 2; infiltrate the carbon fiber felt into the curing agent with a resin mass fraction of 10% resin-alcohol solution until the carbon felt fully absorbs the curing agent, take it out and place it at room temperature until the curing agent stops dripping, and then put it in In a mold with a radian of 2π / n (n is the number of slat units, generally 6-8), pressurize 1.2×10 at 60°C 4 Pa, after curing for 3 hours, raise the temperature to 140°C for deep curing for 8 hours, put it into a high-temperature furnace for carbonization treatment at 1200°C for 48 hours after curing, and finally put it in a vacuum graphite sintering furnace for graphitiz...

Embodiment 2

[0033] The second step is assembled with embodiment 1.

[0034] Example 3

[0035] structured as Figure 5 The specific implementation steps of the preparation method of the shown multi-layer heat insulation cylinder device are as follows:

Embodiment 3

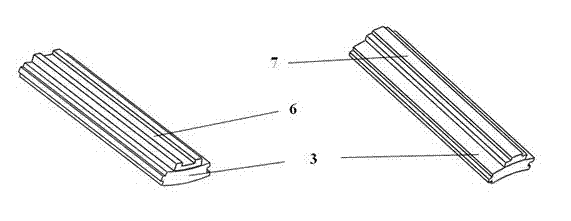

[0037] The second step of assembly: install four chute 6 symmetrically and fixedly on the inner wall of the heat insulation cylinder in the inner layer, and install four guide strips 7 symmetrically on the outer wall of the heat insulation cylinder in the middle layer, connect the chute 6 and the guide strip 7, and the inner layer The sliding between the heat insulation cylinder 1 and the middle layer heat insulation cylinder 8 can be realized by the relative sliding of the chute 6 and the guide bar 7; Cylinder 9 adopts an integral heat insulation cylinder, and the relative sliding between the middle layer heat insulation cylinder and the outer layer heat insulation cylinder is realized by a smooth wall (such as Figure 5 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com