A kind of epitaxial wafer of light-emitting diode and its manufacturing method

A technology of light-emitting diodes and epitaxial wafers, applied in the field of diodes, can solve the problems of strengthening the polarization of quantum well regions, bending the energy band of quantum well regions, and affecting internal quantum efficiency, so as to improve internal quantum efficiency and increase the probability of electron tunneling , Improve the effect of compounding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

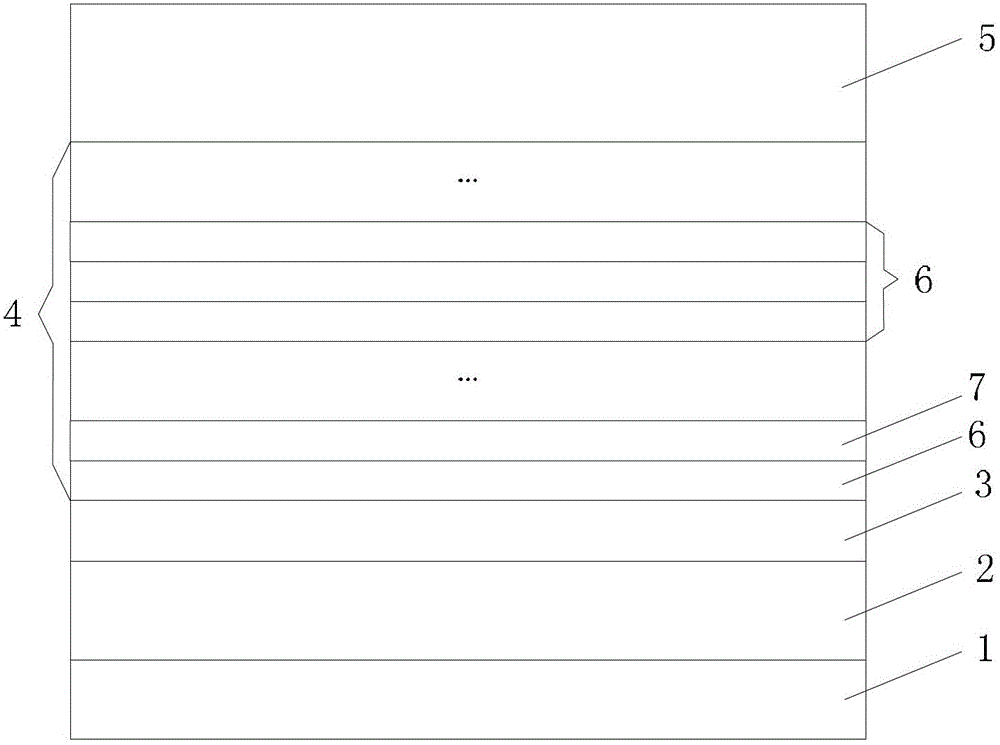

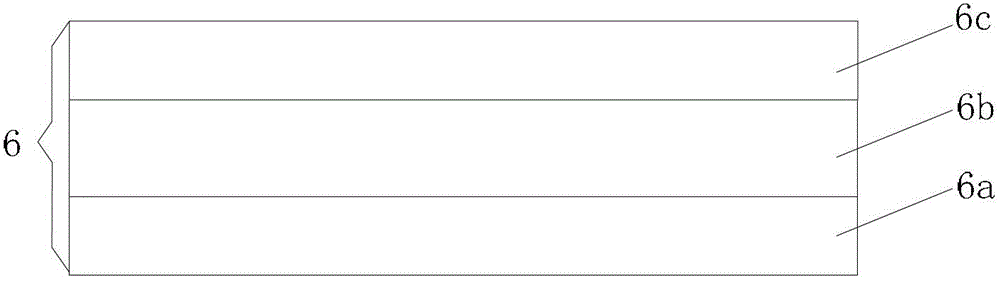

[0021] see figure 1 Embodiment 1 of the present invention provides an epitaxial wafer of a light emitting diode, the epitaxial wafer includes a substrate layer 1, a buffer layer 2 covering the substrate layer 1 in sequence, an N-type layer 3, an MQW layer 4 and a P-type layer 5 The N-type layer 3 is made of n-type doped GaN; the MQW layer 3 includes several quantum barrier layers 6 and several quantum well layers 7 grown alternately with each quantum barrier layer 6 . Wherein, at least one quantum barrier layer 6 in the several quantum barrier layers 6 includes three sub-quantum barrier layers; the sub-quantum barrier layer positioned in the middle of the three sub-quantum barrier layers is made of n-type doped Al x In y Ga 1-x-y N, the n-type doping concentration is not greater than the n-type doping concentration of the N-type layer 3; the other two quantum barrier layers are made of undoped GaN; wherein, 0<x<1, 0<y< 1.

[0022] The beneficial effects brought by the tech...

Embodiment 2

[0024] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode. The epitaxial wafer includes a substrate layer 1 , a buffer layer 2 covering the substrate layer 1 in sequence, an N-type layer 3 , an MQW layer 4 and a P-type layer 5 .

[0025] Specifically, the substrate layer 1 is a sapphire substrate.

[0026] Specifically, the buffer layer 2 is a composite layer, including a low-temperature buffer layer and an undoped GaN layer.

[0027] Specifically, the N-type layer 3 is made of n-type doped GaN. Preferably, its n-type doping is obtained by Si doping, and its doping concentration is 5×10 18 cm -3 .

[0028] Wherein, the MQW layer 3 includes several quantum barrier layers 6 and several quantum well layers 7 grown alternately with each quantum barrier layer 6 . And, at least one quantum barrier layer 6 in all quantum barrier layers 6 comprises three sub-quantum barrier layers; x In y Ga 1-x-y N, the n-type doping concentration is n...

Embodiment 3

[0038] Embodiment 3 of the present invention provides a method for manufacturing an epitaxial wafer of a light-emitting diode. The method includes providing a substrate and sequentially growing a buffer layer, an N-type layer, several quantum barrier layers in the MQW layer, and several Each quantum barrier layer alternates quantum well layers and P-type layers. Wherein, growing at least one quantum barrier layer in the several quantum barrier layers includes:

[0039] growing the quantum barrier layer to a first thickness using undoped GaN;

[0040] n-doped Al x In y Ga 1-x-y N is deposited at a predetermined doping concentration to grow the quantum barrier layer to a second thickness;

[0041] growing the quantum barrier layer to a third thickness using undoped GaN;

[0042] Wherein, the predetermined doping concentration is not greater than the doping concentration of the N-type layer; 0

[0043] Further, the second thickness is 0-10 nm; the first thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com