Efficient machine for desalting sea water

A high-efficiency seawater technology, applied in seawater treatment, general water supply conservation, heating water/sewage treatment, etc., can solve the problems of low energy utilization rate of seawater desalination devices, insufficient effective heat transfer area, and low single-machine water production capacity. Achieve the effect of improving energy utilization rate, heat release coefficient and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

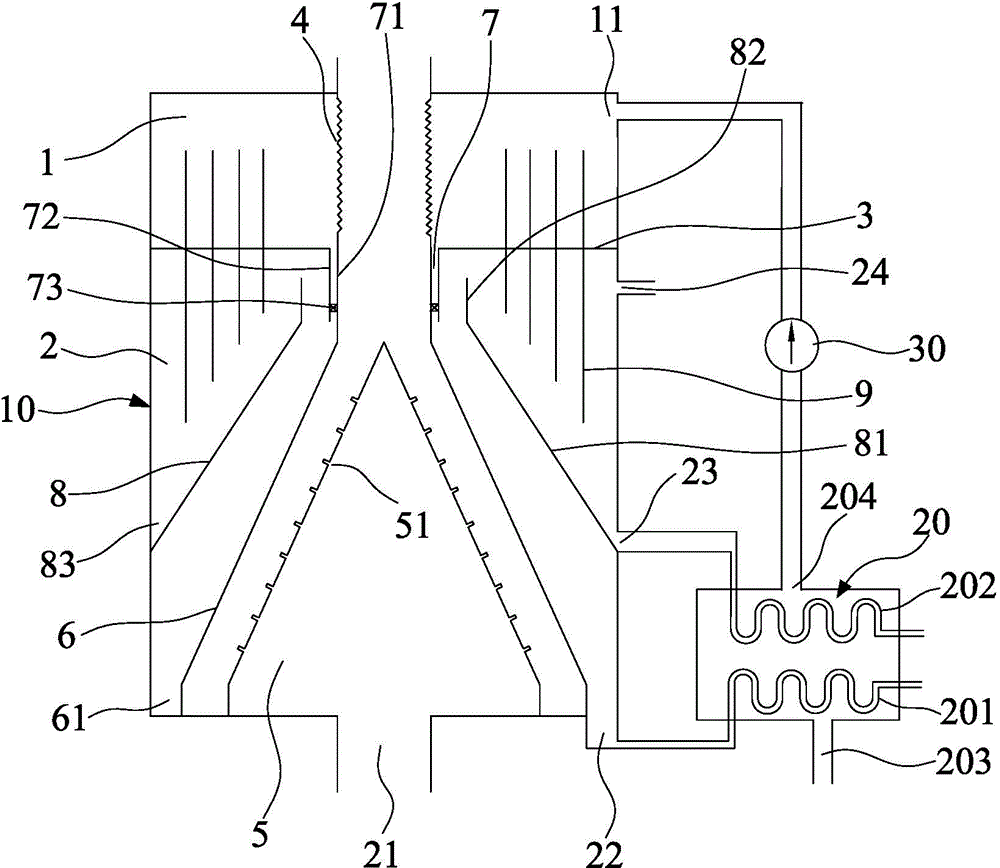

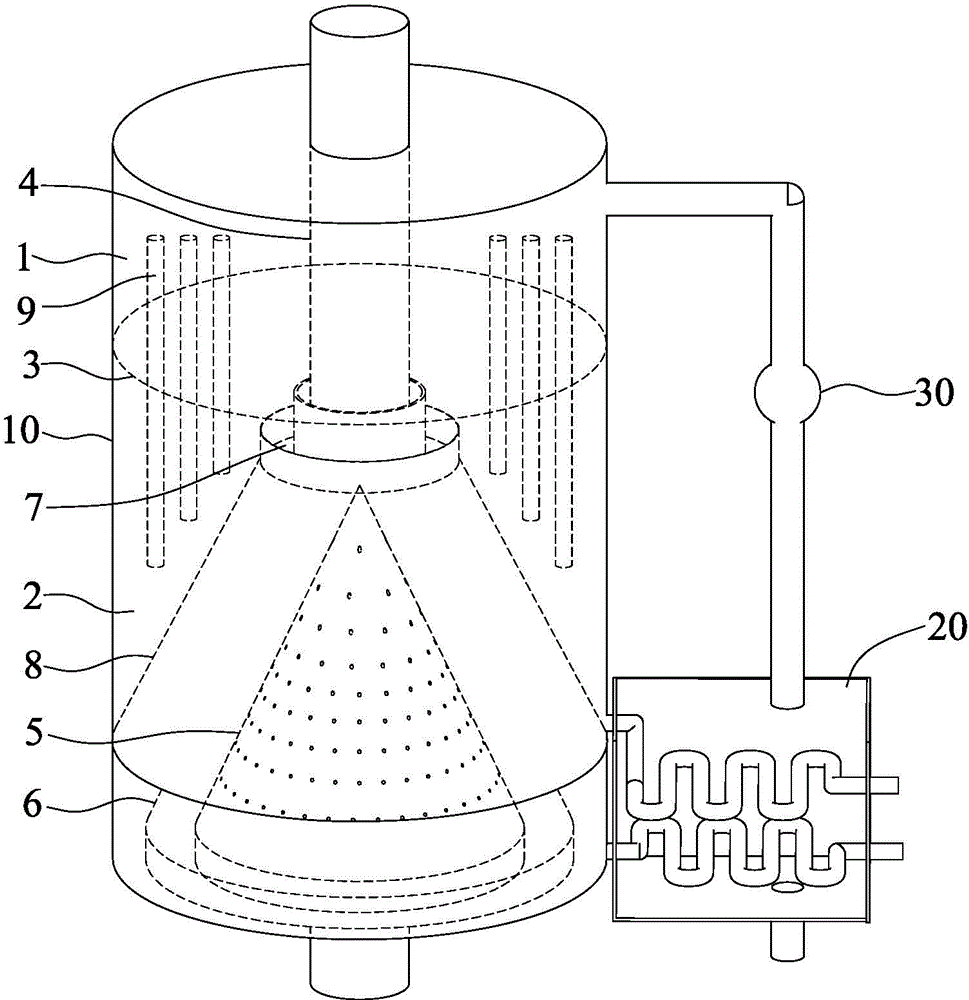

[0016] Such as figure 1 , figure 2 As shown, the present invention is a high-efficiency seawater desalination machine, which includes a seawater desalination device 10 and a water supply tank 20 .

[0017] The seawater desalination device 10 is connected to the water supply tank 20 through pipelines.

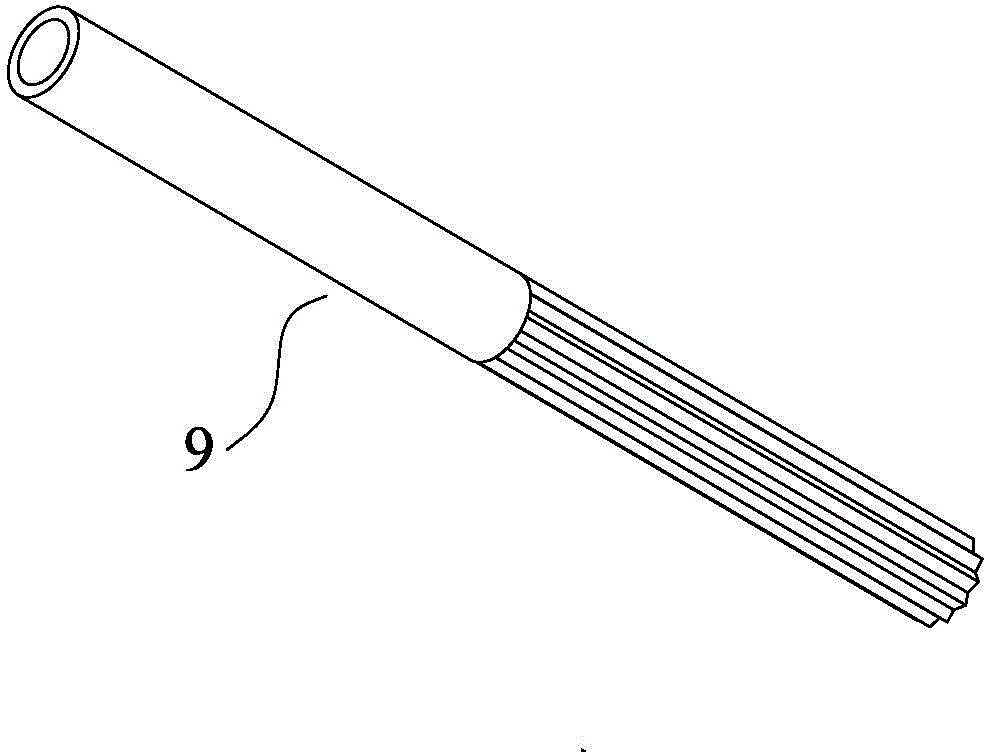

[0018] The seawater desalination device 10 is a vertical airtight container, which mainly consists of a high-pressure water chamber 1, a heat exchange chamber 2, a tube plate 3, a horizontal grooved pipe 4, an injector 5, a heat exchange surface 6, and a film forming device 7 , a baffle plate 8 and a plurality of heat pipes 9; the sewage cooling pipe 201 and the desalinated water cooling pipe 202 are arranged in the water supply tank 20; the high-pressure water chamber 1 is adjacent to the heat exchange chamber 2, and the high-pressure water chamber 1 Located above the heat exchange chamber 2, the two chambers are separated by a tube plate 3; the wall of the high-pressure wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com