Polyurethane composite material and preparation method thereof

A technology of polyurethane and composite materials, applied in the field of polyurethane composite materials and their preparation, can solve the problems of high recovery cost, high cost, easy rust and the like, and achieves low cost, low water absorption, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

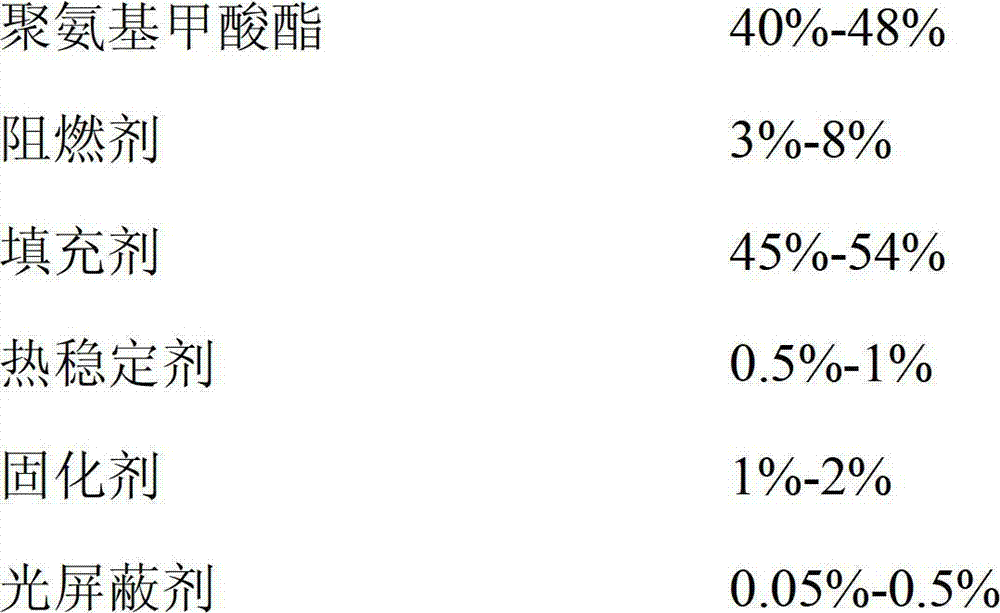

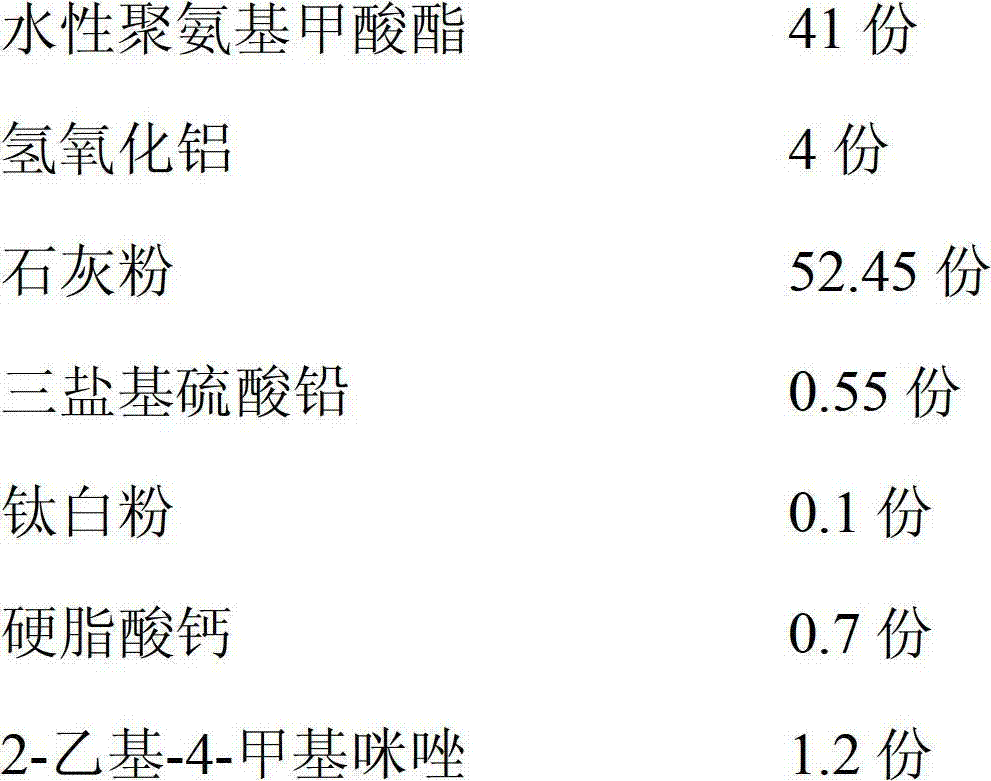

[0029] Embodiment 1, preparation polyurethane comprises following raw material:

[0030]

[0031] The PU resin in the formula is preferably water-based polyurethane, and the water-based polyurethane (PU) can be 80UD of BAYER company, D-16 of BASF company, W2901H of WITTCOL company or anionic external emulsification water-based polyurethane ester (PU). In this embodiment, the inorganic flame retardant is preferably aluminum hydroxide, the filler is preferably lime powder, the heat stabilizer is preferably tribasic lead sulfate, the light shielding agent is preferably titanium dioxide, the lubricant is preferably calcium stearate, and the curing agent is preferably 2- Ethyl-4-methylimidazole.

[0032] The specific preparation method is as follows:

[0033] Step 1: Use an electronic scale to weigh various raw materials by weight percentage;

[0034] Step 2: Mix 41 parts of polyurethane, 4 parts of aluminum hydroxide, and 52.45 parts of lime powder in a mixer at high speed f...

Embodiment 2

[0043] Embodiment 2, preparation polyurethane comprises following raw material:

[0044]

[0045] The specific preparation method is as follows:

[0046] Step 1: Use an electronic scale to weigh various raw materials by weight percentage;

[0047] Step 2: Mix 42 parts of polyurethane, 4.5 parts of aluminum hydroxide, and 50.5 parts of lime powder in the formula in a mixer at high speed for 5-10 minutes, and then add 0.6 parts of tribasic sulfuric acid in sequence after stirring evenly After lead, 0.2 parts of titanium dioxide, 0.8 parts of calcium stearate, and 1.4 parts of 2-ethyl-4-methylimidazole, continue to stir and mix for 2-4 minutes;

[0048] Step 3: Take out the mixed liquid obtained in step 2, pour it into the epoxy resin model mold, and vibrate the epoxy resin mold manually or by machine for 20-30 minutes at room temperature;

[0049] Step 4: Open the epoxy resin model mold, and remove the cured and formed complete product from the mold.

Embodiment 3

[0050] Embodiment 3, preparation polyurethane comprises following raw material:

[0051]

[0052]

[0053] The specific preparation method is as follows:

[0054]Step 1: Use an electronic scale to weigh various raw materials by weight percentage;

[0055] Step 2: Mix 43 parts of polyurethane, 5 parts of aluminum hydroxide, and 48.55 parts of lime powder in a mixer at high speed for 5-10 minutes, and then add 0.65 parts of tribasic sulfuric acid in sequence after stirring evenly After lead, 0.3 parts of titanium dioxide, 0.9 parts of calcium stearate, and 1.6 parts of 2-ethyl-4-methylimidazole, continue to stir and mix for 2-4 minutes;

[0056] Step 3: Take out the mixed liquid obtained in step 2, pour it into the epoxy resin model mold, and vibrate the epoxy resin mold manually or by machine for 20-30 minutes at room temperature;

[0057] Step 4: Open the epoxy resin model mold, and remove the cured and formed complete product from the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com