Numerical control gear grinding machine for formed grinding wheel

A technology for forming grinding wheels and gear grinding machines, which is applied in the direction of gear teeth, gear cutting machines, gear teeth manufacturing devices, etc., can solve the problems of increased production costs, time-consuming, process errors, etc., to achieve less time-consuming, increase production efficiency, The effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to further clarify the present invention, the embodiments of the present invention are now described in detail.

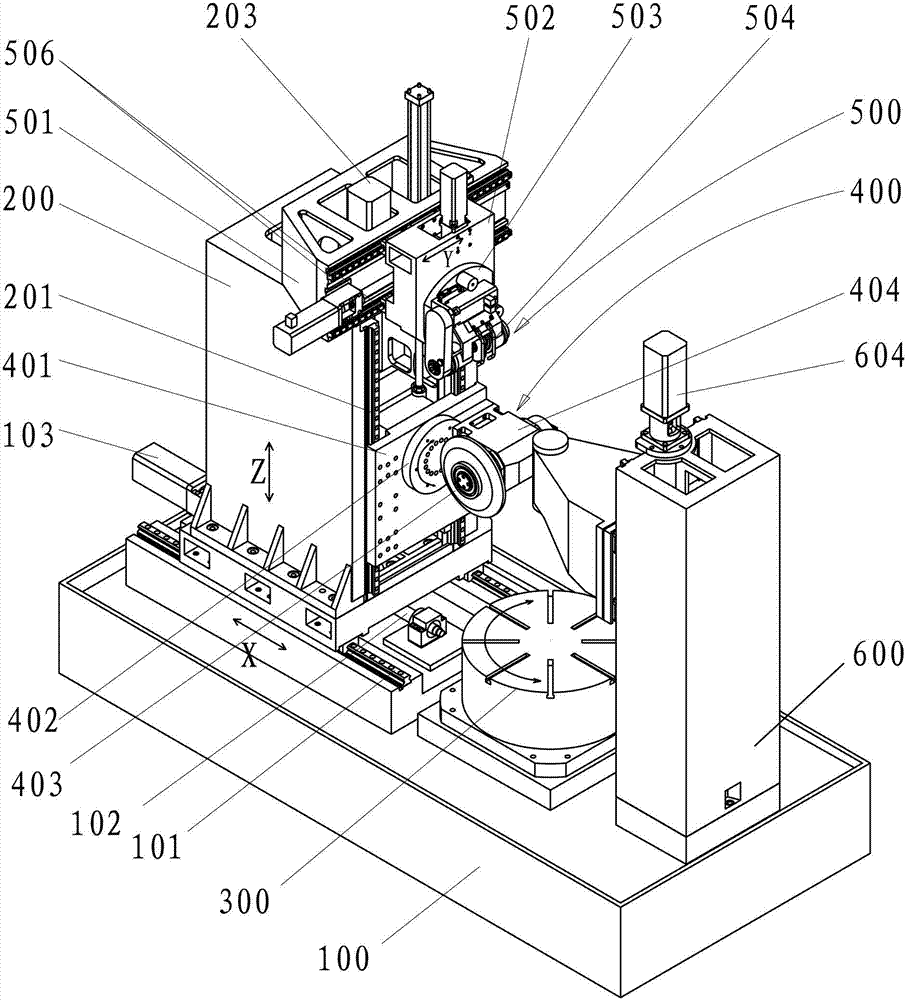

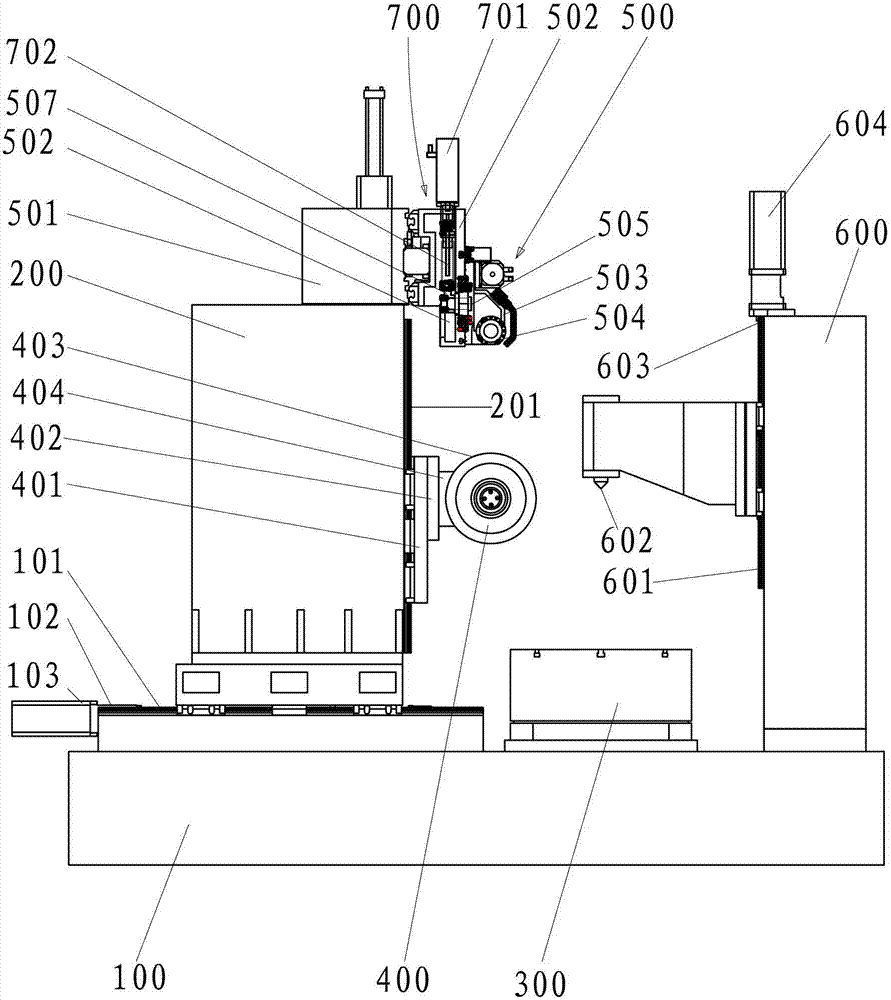

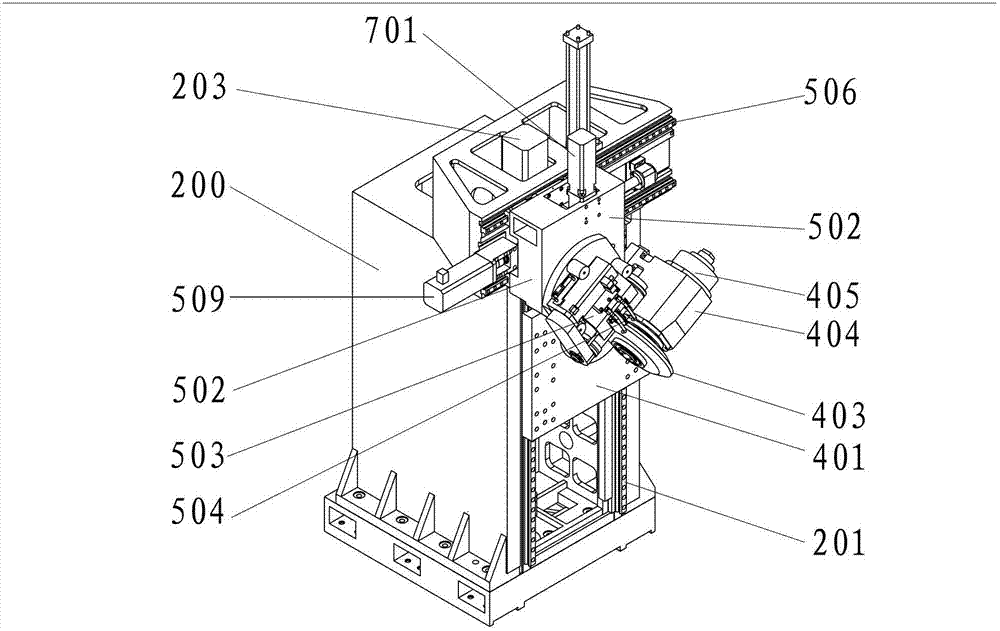

[0063] see figure 1 , 2 As shown, a CNC forming grinding wheel gear grinding machine includes a machine base 100, a main column 200, a workpiece rotating part 300, a grinding device 400 and a dressing device 500;

[0064] see figure 1 , 2 , 4, the base 100 includes an X-direction rolling guide 101, and the X-direction of the present invention is defined as attached figure 1 As shown, it is the central direction of the long axis of the machine base 100; the main column 200 is slip-fitted on the X-direction rolling guide rail 101 and can move relatively along the X direction; the workpiece rotating part 300 is fixed on the machine base 100; The base 100 is provided with a lead screw 102 for driving the main column 200 to move relative to the X-direction rolling guide 101 and a servo motor 103 for providing power to the lead screw 102 .

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com