Preparation of pentane through hydrogenation of lightweight C5 fraction

A C5-fraction, light-weight technology, which is applied in the field of hydrogenation reaction to prepare pentane, can solve the problems of inapplicable hydrogenation of light C5-fraction, and achieve the effect of improving stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

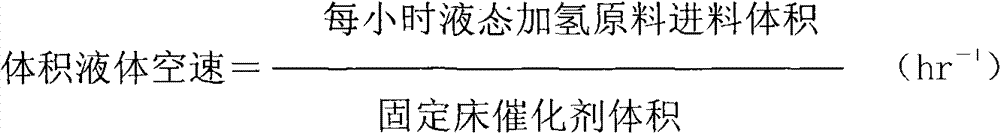

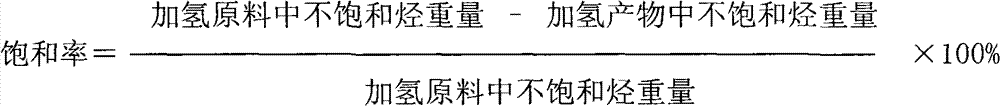

Method used

Image

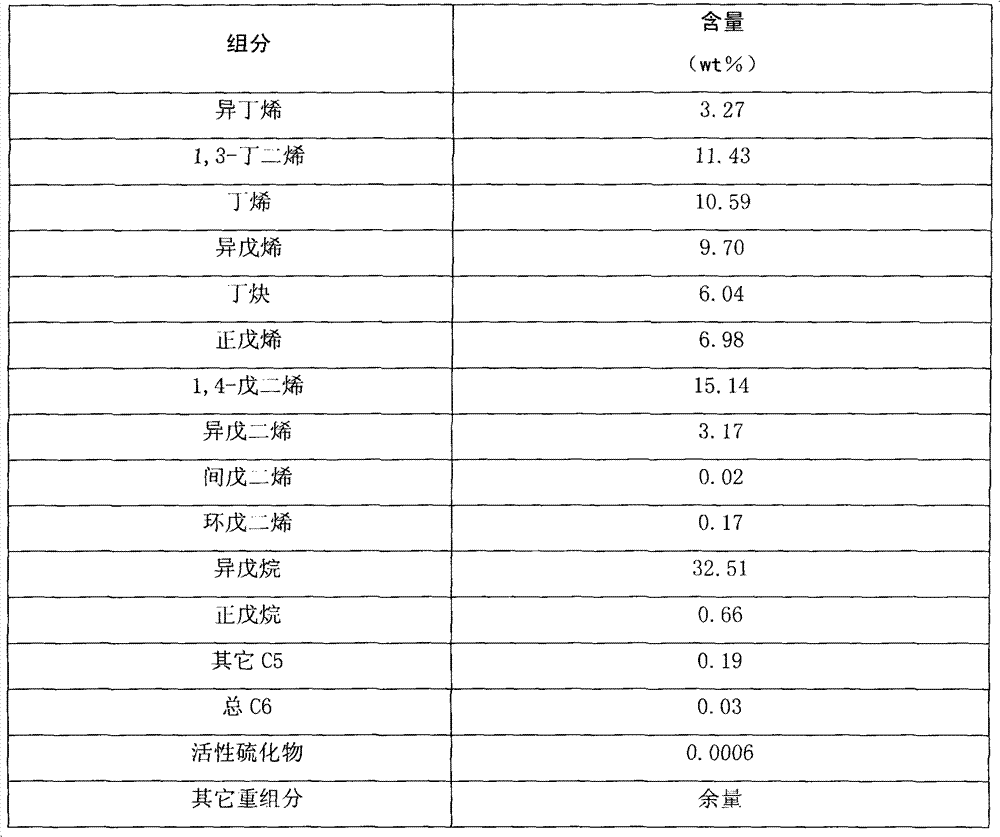

Examples

Embodiment 1~10

[0025] The hydrogenation reaction is carried out in a stainless steel tubular reactor, and the reactor is a stainless steel tubular reactor with a size of φ25mm×1000mm. 100ml of catalyst is filled in the reaction tube. The catalyst is a supported catalyst with Ni as the active component and diatomite as the carrier. The weight percentage of Ni in the catalyst is 30-50%. The bottom of the reactor is filled with inert ceramic balls. The fresh catalyst needs to be activated with hydrogen before feeding.

[0026] The light carbon five fraction material is mixed with the hydrogenation product prepared in the previous experiment, and after preheating, the pump is used to send the hydrogenation reactor from the top at a set rate, and the mixed gas of hydrogen and CO enters the reactor through the gas distributor Inside, the light carbon five fraction material is mixed with the mixed gas of hydrogen and CO, and then enters the catalyst bed for hydrogenation reaction. The hydrogenatio...

Embodiment 11~15

[0041]Take part of the hydrogenation products obtained in the examples to remove residual unsaturated hydrocarbons and remove light components to obtain pentane products.

[0042] The hydrogenated product first passes through an adsorption reactor to remove unsaturated hydrocarbons. The adsorption reactor is a stainless steel tubular reactor, including a φ25mm×1000mm reaction tube, filled with granular clay, the granular clay has a particle size of 20-60 mesh, an acidity of ≤2.5KOHmg / g, and a packing density of 0.65-0.70 g / ml.

[0043] The deunsaturated hydrogenated product is then separated by rectification to remove the light ends. The theoretical plate number of the rectification tower is 20, the light fraction material is discharged from the top of the tower, and the product pentane is obtained at the bottom of the tower.

[0044] The process conditions of each embodiment adsorption process and rectification separation process are shown in Table 3.

[0045] Product pent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com