Degradable multiband light conversion ground film and preparation method thereof

A multi-band, plastic film technology, applied in the direction of plant protection covers, can solve the problems of non-degradability, affecting the growth rate of crops, high cost, etc., and achieve the effect of improving the quality of crops, promoting the growth of crops, and increasing the quality of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 377g Y 2 o 3 and 10.56g Eu 2 o 3 Dissolve in concentrated hydrochloric acid under magnetic stirring, distill off water and excess hydrochloric acid under reduced pressure at 70oC, then add 3 liters of ethanol solution containing NaCl (20g) and stir to obtain a clear and transparent solution, add 100g SiO 2 Aerosol, 65 o C under magnetic stirring for 90min to obtain a transparent sol, under reduced pressure distillation to remove ethanol under stirring to obtain a powder solid, transfer to a muffle furnace 600 o C was sintered for 3 hours to obtain yttrium europium silicate light conversion powder. Take the 200g yttrium europium silicate light-transforming powder, 10g rhodamine B and 1790g polylactic acid masterbatch, add it into the mixer and stir evenly, then send it into the blown film extruder, and obtain the polyamide after the extruded film is cooled. Lactic acid conversion film. The thickness of the prepared film is about 0.014mm.

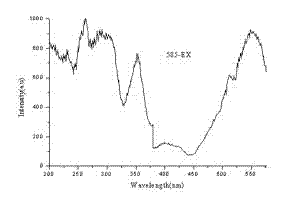

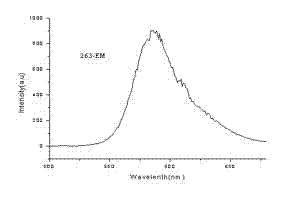

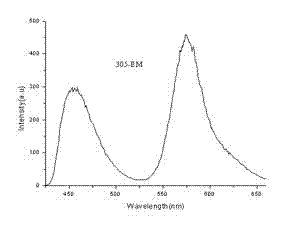

[0040] like figure ...

Embodiment 2

[0042] The polylactic acid light-converting mulching film of Example 2 was prepared as in Example 1, except that the amount of rhodamine B added was 1 g, and the amount of polylactic acid masterbatch was 1799 g.

Embodiment 3

[0044] The polylactic acid light conversion film of Example 3 was prepared as in Example 1, except that the amount of yttrium europium silicate light conversion powder added was 40 g, and the amount of polylactic acid masterbatch was 1950 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com