High-temperature sintering furnace

A high-temperature sintering and furnace body technology, applied in the field of sintering furnaces, can solve the problems of uneven heat, threats to workers' personal safety, uneven hardness of TC bearings, etc., and achieve the effect of improving the dissolution quality and shortening the sintering time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

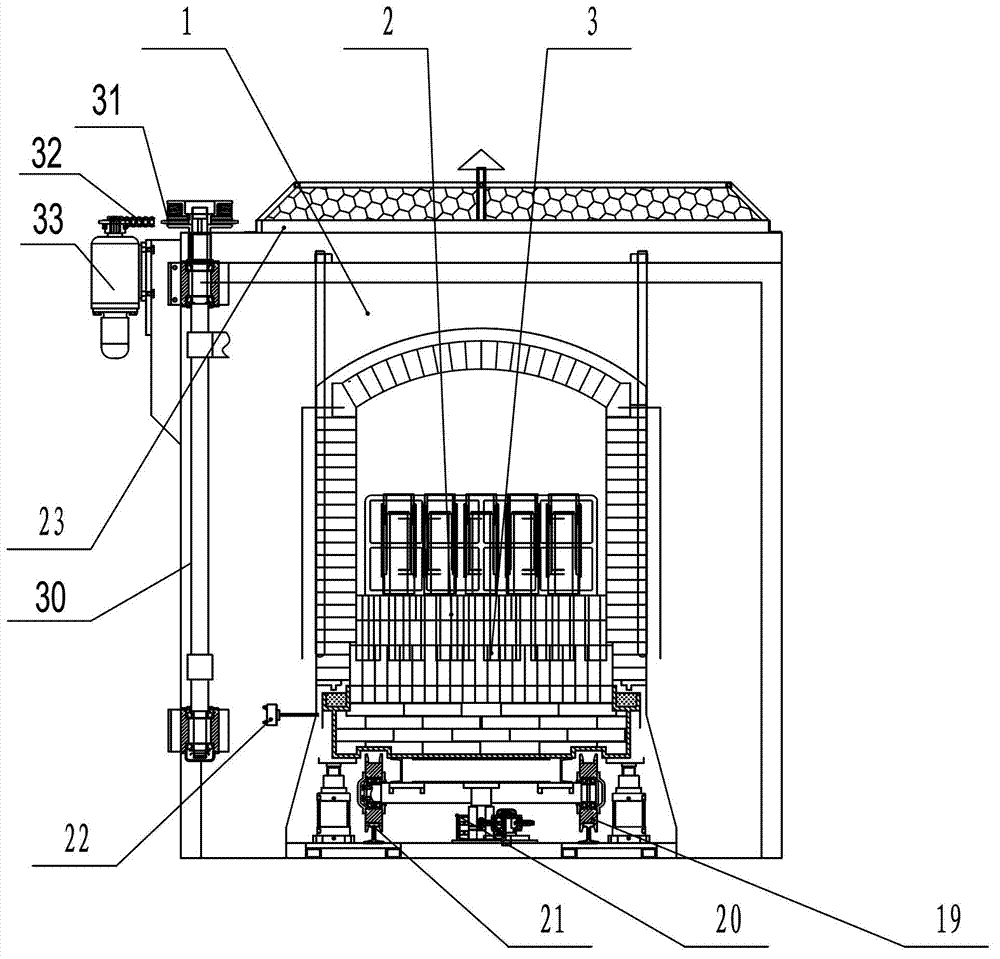

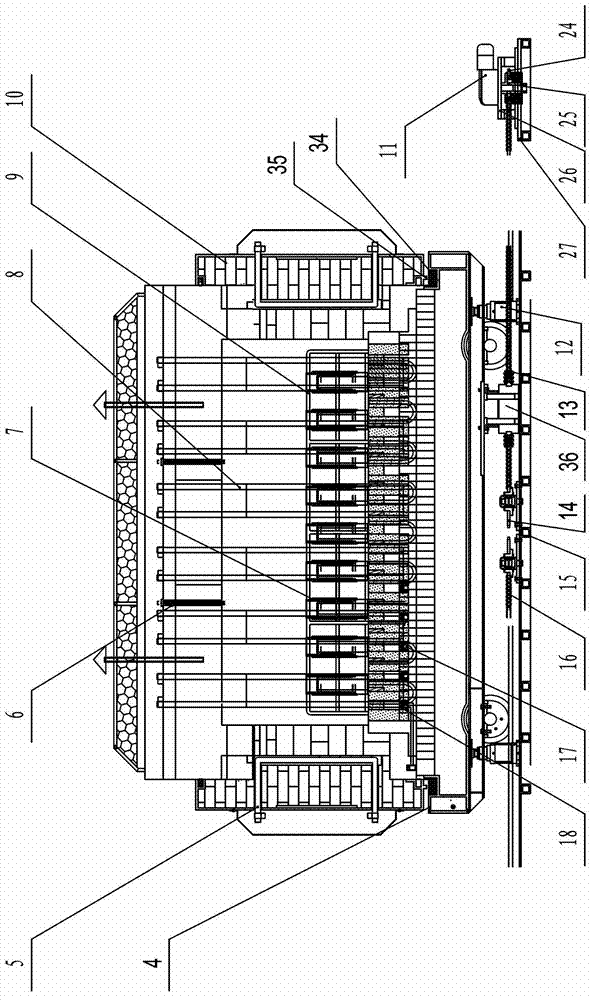

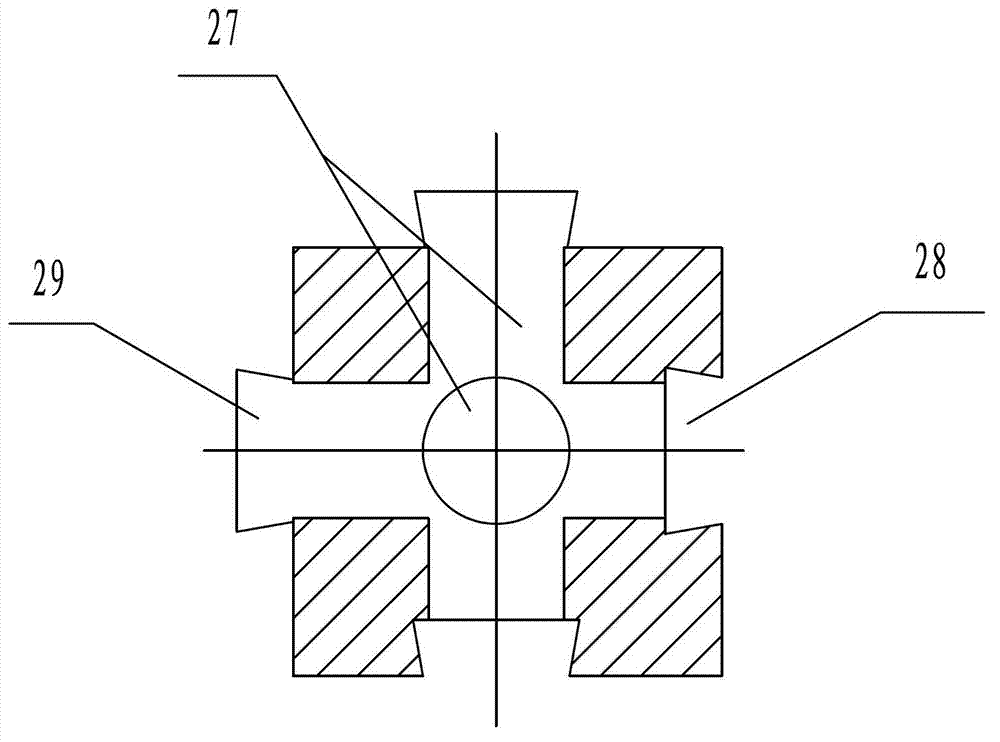

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1 to Figure 3 Shown: a high-temperature sintering furnace, including a furnace body 1 with heating rods 8, a workpiece car 4 arranged at the bottom of the furnace body, a driving mechanism for driving the workpiece car, and a lifting mechanism for lifting the workpiece car , the lifting mechanism in the present invention is preferably a hydraulic cylinder 12 . The workpiece car bottom is provided with four wheels 19, and the wheels run on rails 21 fixed on the ground. In order to make the heating and cooling of the TC bearing uniform, the upper part of the workpiece car is tiled with refractory bricks 3 along the length direction of the workpiece car. The upper part of the refractory bricks is provided with hollow refractory bricks. Through holes 27 are respectively provided in the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com