Potentiometric titration method of mixed acid concentration in aluminum etching liquid

A potentiometric titration and aluminum etching technology, applied in the field of etching solution, can solve the problems of reducing the accuracy and repeatability of the titration result, increasing the uncertainty of the titration result, and the complicated operation of the titration process, so as to achieve the effect of reducing the complexity of the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

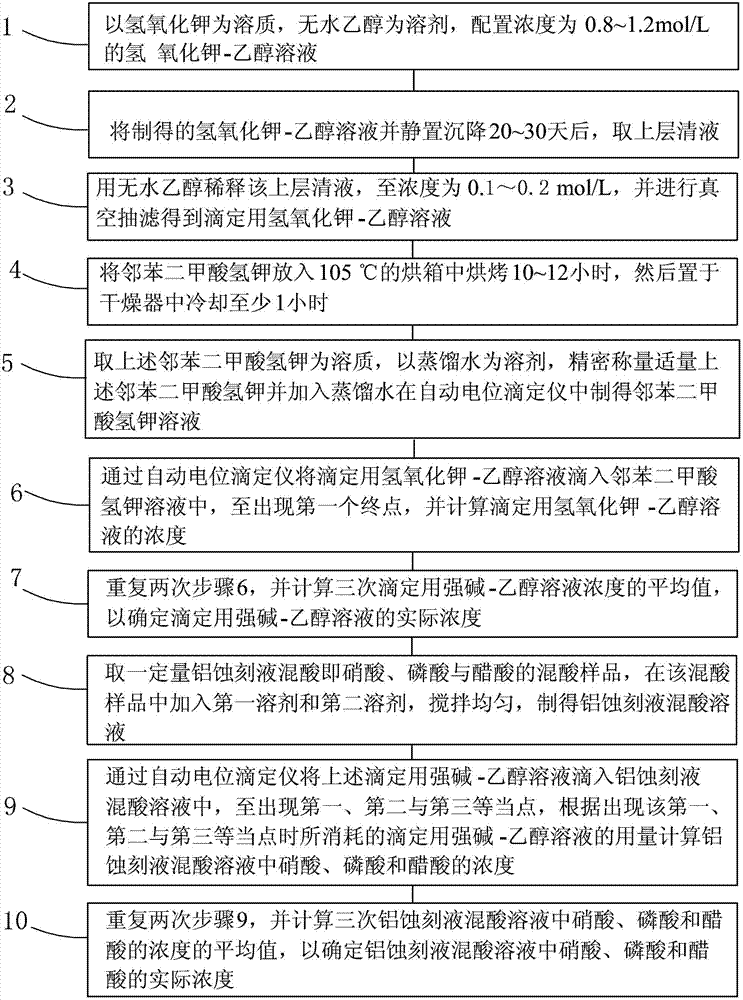

[0038] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

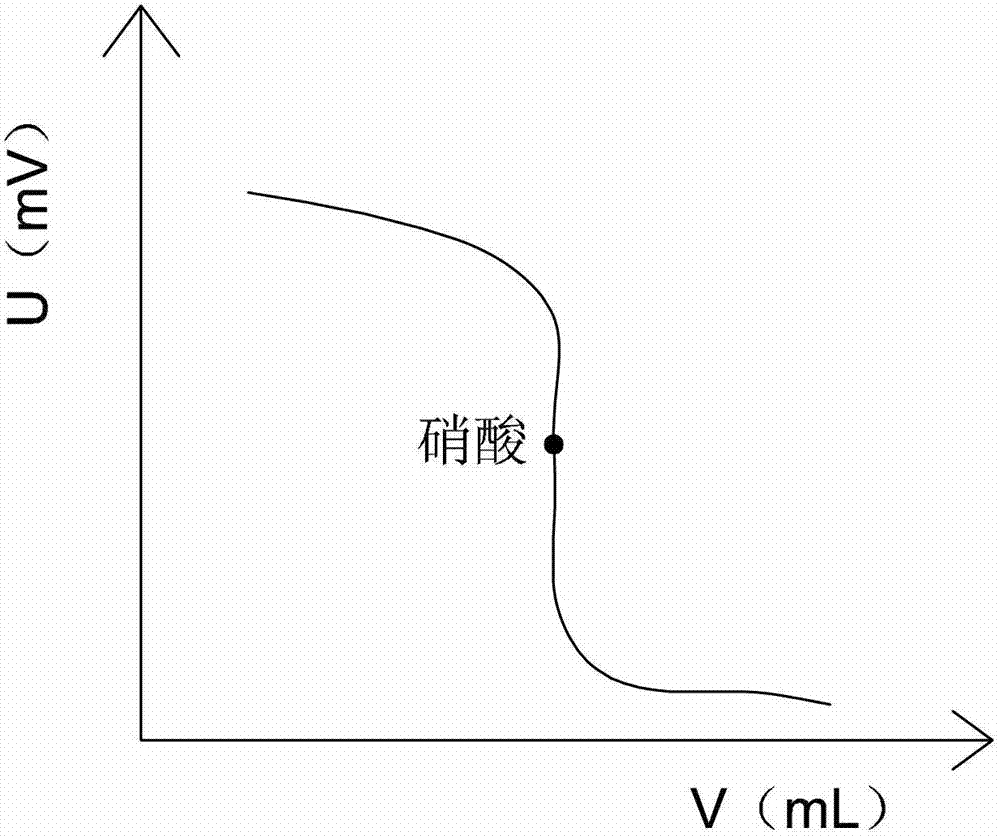

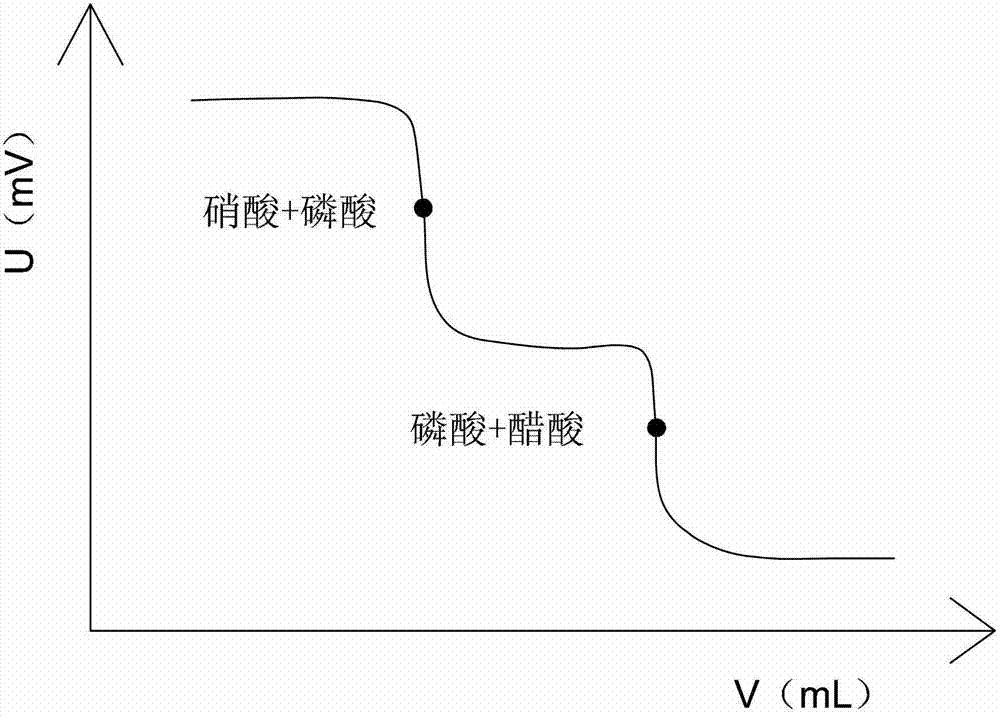

[0039] see figure 2 and image 3 , the present invention provides a kind of potentiometric titration method of the mixed acid concentration of aluminum etching solution, the potentiometric titration method of the mixed acid concentration of aluminum etching solution of the present invention adopts monohydric alcohol and dibasic alcohol as the non-aqueous medium of aluminum etching solution mixed acid, with strong base- Ethanol solution is titrant, realizes single-acid concentration in one-step potentiometric titration aluminum etching solution mixed acid, and described strong base can be potassium hydroxide, and its analytical pure (AR) concentration is greater than or equal to 85%; Described strong base can also be For sodium hydroxide, its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com