Assembling method for quality analytical instrument with four-pole rods

A mass analyzer and assembly method technology, which is applied to mass spectrometers, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of difficult processing and assembly, difficult processing and assembly adjustment, and high precision requirements. The effect of precision performance, solving technical problems, and guaranteeing assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

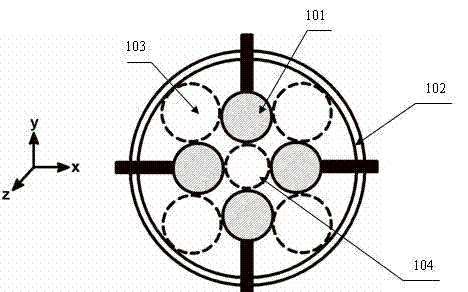

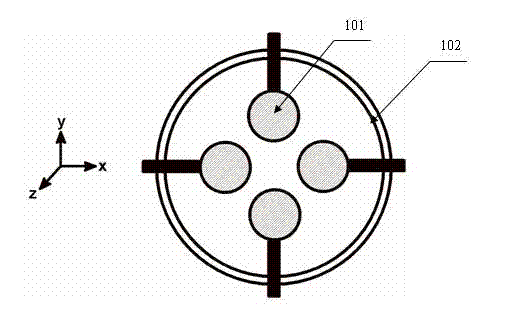

[0032] see Figure 1~4 As shown, the present invention discloses an assembly method of a quadrupole mass analyzer. During the assembly process, four electrode rods 101, two insulating rings 102, a positioning fixture 103, a positioning fixture 104 and other components are mainly used.

[0033] The electrode rods are cylindrical metal rods, and the insulating rings are cylinders processed from ceramics, located at the two ends of the four electrode rods. The positioning jig 103 and the positioning jig 104 are made of ceramic (99.6% aluminum oxide) balls or cylinders.

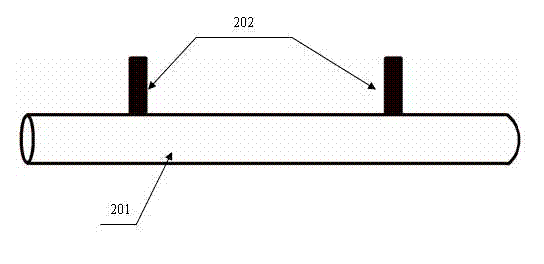

[0034] image 3 Shown in is a schematic diagram of the structure of the electrode rod, wherein the two ends of the electrode rod 201 are provided with positioning pins 202, and the positioning pins are made of metal materials. The positioning pins 202 are integrally processed with the electrode rod 201, or a positioning groove is processed on the electrode rod 201 , the positioning pin 202 is placed in the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com