Optical film and method for producing the same

A manufacturing method and technology of optical films, applied in the field of optical films, can solve the problems of low anti-glare, unclear image display, easy to produce cracks, etc., to improve keystroke durability, improve scratch resistance and mechanical properties, The effect of suppressing oozing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

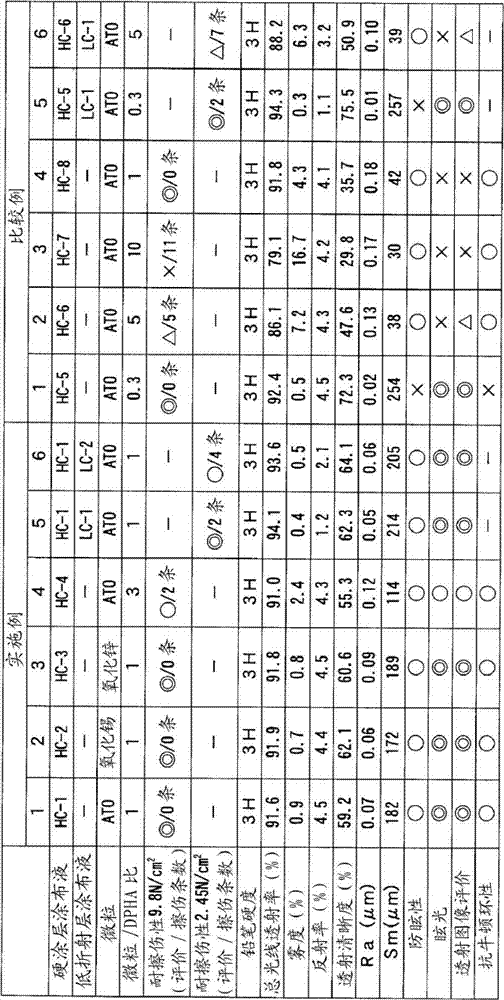

Embodiment 1

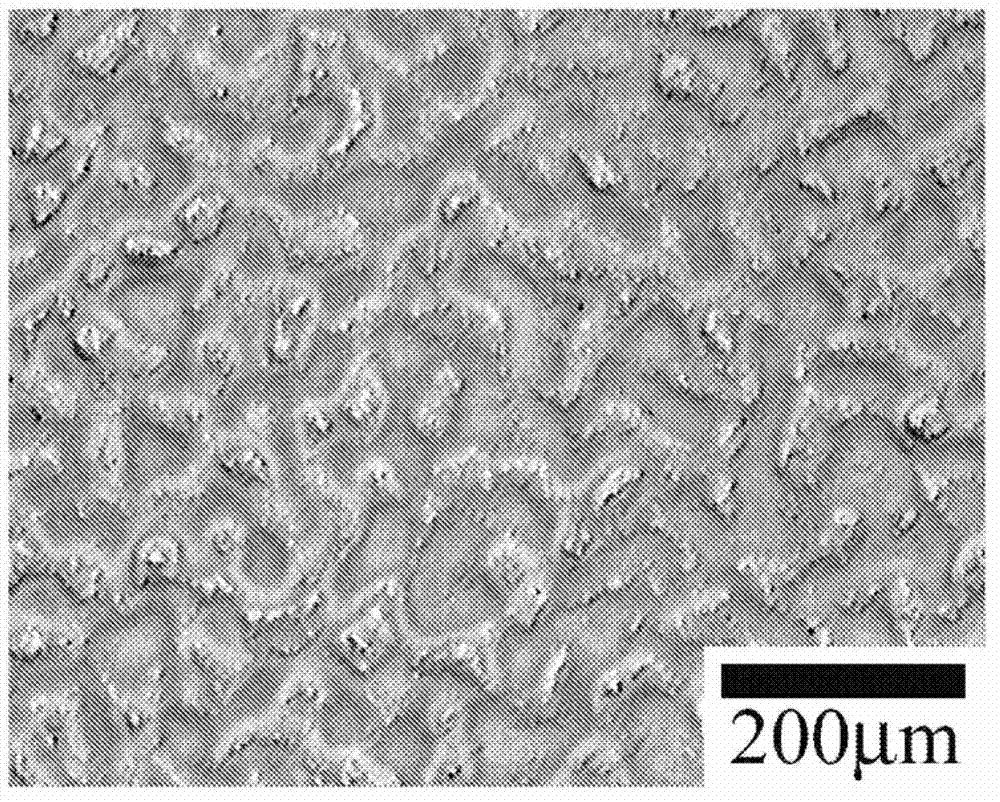

[0175] Using a cellulose triacetate film (manufactured by Fujifilm Co., Ltd., TAC, thickness 80 μm) as a transparent film, the hard coat coating liquid HC-1 was coated on the film with a bar coater #30, and then Dry at 70°C for 1 minute. Ultraviolet irradiation device (manufactured by Ushio Electric Co., Ltd., high-pressure mercury lamp, ultraviolet irradiation amount: 800mJ / cm 2 ) to UV-cure the coating film to form a hard coating with a hard coating and a concave-convex structure. The thickness of the hard coat layer in the obtained optical film was about 10 μm. The surface of the obtained optical film was observed with a laser microscope, and the results are shown in figure 1 .

Embodiment 2

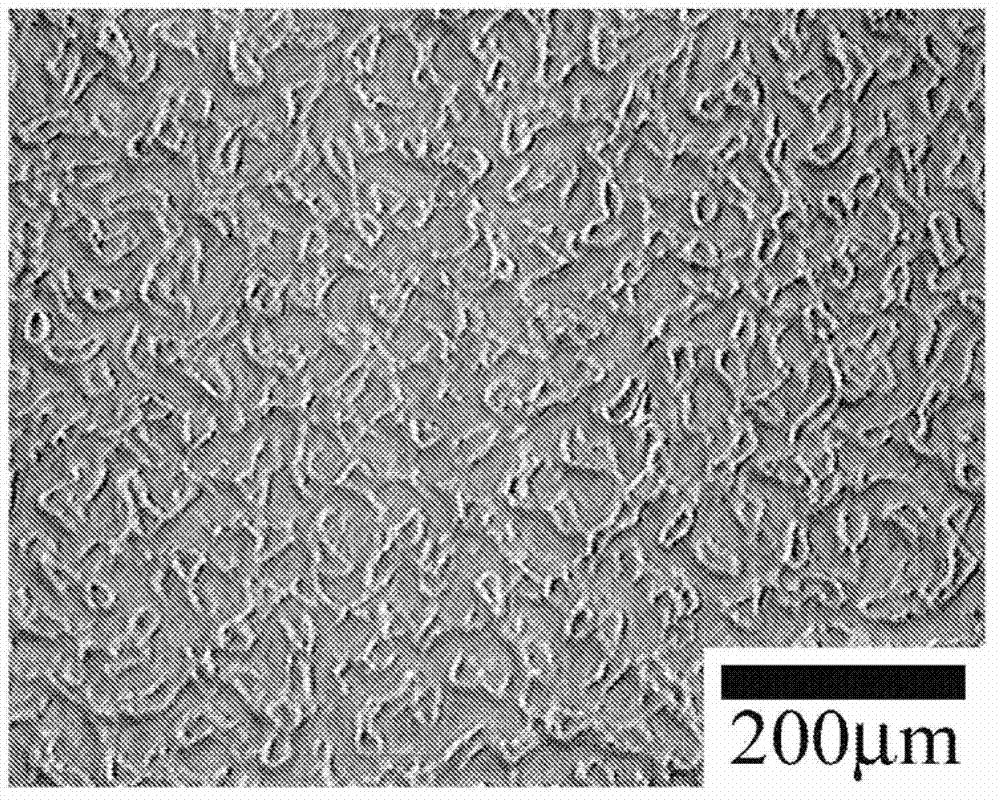

[0177]An optical film was produced in the same manner as in Example 1 except that hard coat coating liquid HC-2 was used instead of hard coat coating liquid HC-1.

Embodiment 3

[0179] An optical film was produced in the same manner as in Example 1 except that hard coat coating liquid HC-3 was used instead of hard coat coating liquid HC-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com