Comprehensive utilization method of catalytic cracking gasoline sludge

A technology for catalytic cracking of gasoline and alkali slag, which is applied in the direction of chemical instruments and methods, preparation of alkali metal compounds, organic compounds, etc., can solve the problems of inability to form economies of scale, complex process flow, complex purification treatment, etc., and achieve the reduction of easily oxidized Possibility of deterioration, simple process flow, effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

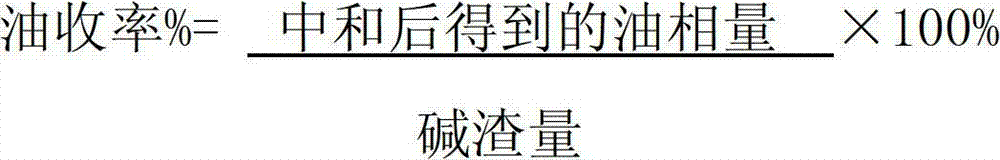

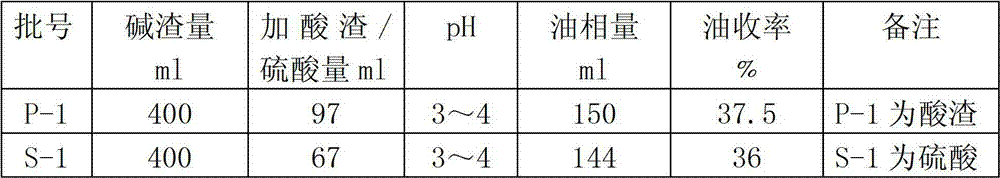

[0027] Take 400ml of catalytic cracking gasoline alkali residue and place it in a 500ml beaker, neutralize it with alkylated acid residue until the acidity reaches pH 3-4, stir for 20-30 minutes, and control the temperature at 40-50°C to reduce light The oil evaporates. After standing still, the layers were separated, and the upper oil phase was taken out to obtain P-1. The results are shown in Table 1.

Embodiment 2、3

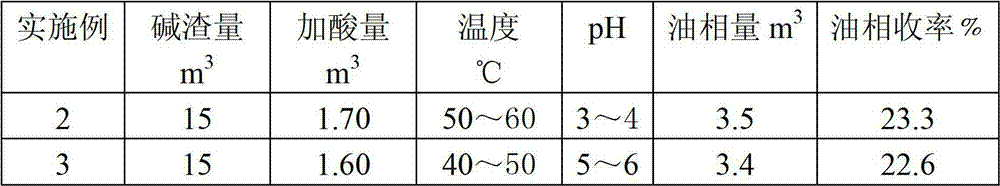

[0033] Add 15m 3 Catalyzed cracking gasoline alkali slag is put in the reactor, add alkylated acid slag, control the reaction temperature at 40-60°C, stir at 100 rpm, stop adding acid when the pH is 3-6, and the H discharged from the top of the kettle 2 S and other gases are absorbed with waste lye, continue to stir for 20 to 30 minutes, put them into the separation tank, and let them stand for 2 to 3 hours. The water phase is separated from the oil phase. The oil phase yield is shown in Table 2.

[0034] Table 2 15m 3 Device neutralization reaction results

[0035]

Embodiment 4

[0037] Take the oil phase produced in Example 2 and put it into the distillation bottle of the glass distillation device with a distillation column of ф38×300mm, first carry out atmospheric distillation, control the temperature at the top of the tower at 80-94°C, and collect the water-containing light oil product. Then conduct moderate vacuum distillation, control the tower top temperature at 150-160°C, and the gauge pressure at 280-300mmHg to collect crude phenol products. The results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com