Crack self-healing bituminous concrete and preparation method thereof

A self-healing technology for asphalt concrete, applied in the field of asphalt concrete, can solve problems such as the influence of the self-healing ability of asphalt pavement cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

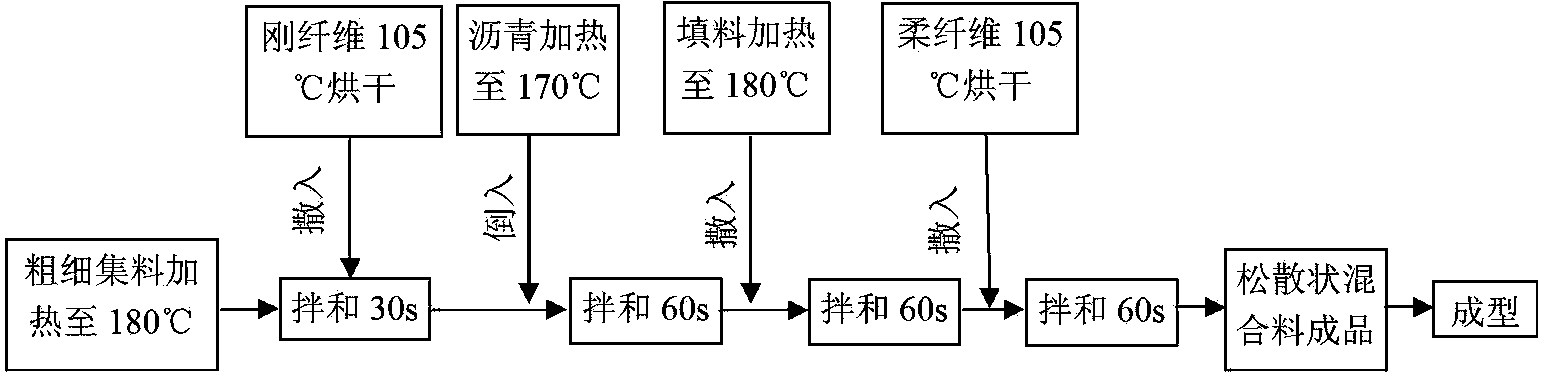

[0018] The invention provides the preparation method of the above-mentioned crack self-healing asphalt concrete, including material preparation, mixing and molding processes, such as figure 1 As shown, the specific steps are as follows:

[0019](1) Material preparation: The quality of coarse aggregate, fine aggregate and filler is weighed in proportion according to the median value of densely graded asphalt concrete AC-13 gradation specified in JTG F40-2004, and the coarse aggregate, fine aggregate and filler Put them in an oven at 105°C±5°C and dry to constant weight; test the density of mineral aggregates and asphalt with various particle sizes according to the method specified in JTJ 052-2000 Test Procedures for Asphalt and Asphalt Mixtures in Highway Engineering; and then according to JTG F40— 2004 Appendix B.6 determines the asphalt ratio of asphalt concrete composed of coarse aggregate, fine aggregate, filler and asphalt, and the asphalt ratio of the crack self-healing c...

Embodiment 1

[0025] This embodiment provides a method for preparing crack self-healing asphalt concrete.

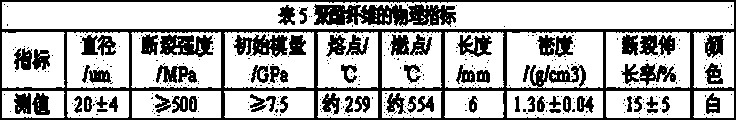

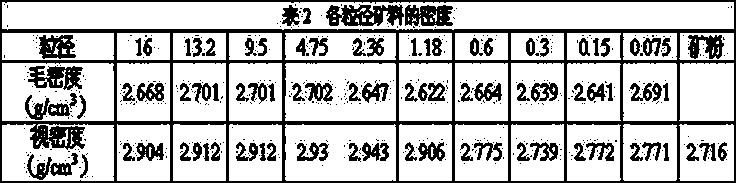

[0026] (1) Material preparation: The quality of porous basalt aggregates with a particle size of 1.18mm or more, limestone aggregates with a particle size of 1.18mm or less and finely ground limestone powder shall be in accordance with the densely graded asphalt concrete AC-13 grade specified in the specification JTG F40-2004 Mixing (see Table 1) median value is weighed in proportion, porous basalt aggregate, limestone aggregate and finely ground limestone powder are placed in an oven at 105°C ± 5°C and dried to constant weight; Test the density of porous basalt aggregates, limestone aggregates, ground limestone and heavy traffic AH-70 asphalt by the method specified in JTJ 052-2000 in the test procedure for mixtures (see Table 2); then determine according to JTG F40-2004 Appendix B.6 The asphalt ratio of the asphalt concrete composed of porous basalt aggregate, limestone aggregate, g...

Embodiment 2

[0039] The same part of this example and Example 1 will not be repeated, the difference is that 0.5% wt of the total mass of the porous basalt aggregate, limestone aggregate, ground limestone powder and heavy traffic AH-70 asphalt is mixed with steel fiber .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com