Preparation method for conductive timber

A wood and conductive polymer technology, applied in the direction of non-metallic conductors, organic material conductors, etc., can solve the problems of waste, material transition consumption, etc., and achieve the effect of convenient operation, good strength-to-weight ratio, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

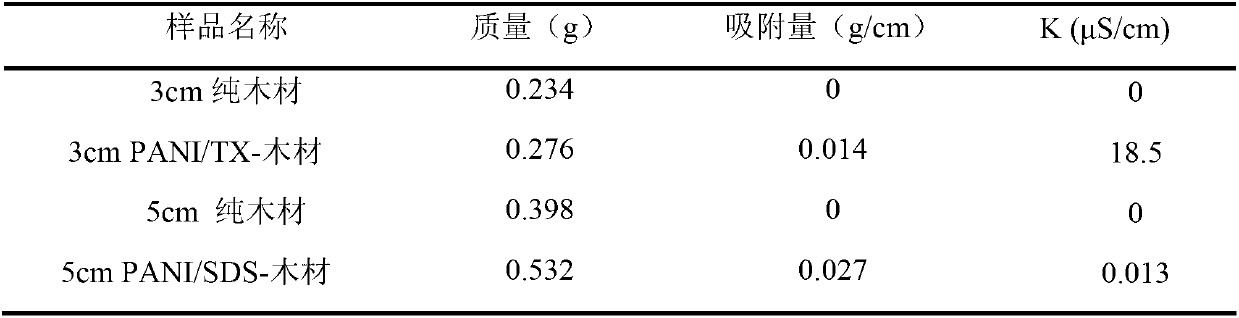

Embodiment 1

[0035] Doping with TX-100 (polyethylene glycol octylphenyl ether) to prepare polyaniline and import it into wood

[0036] (1) Measure 1-10mL of aniline, slowly add 1-500mL of 0.1-1M HCl solution under stirring; then add 1-10mL of Triton X-100, 1-10mL of n-hexanol and n-hexane mixture ( Among them, the volume ratio of n-hexanol and n-hexane is 1-10:1-5), after adding, stir first, and then vibrate in ultrasonic wave for 1-60min to obtain transparent microemulsion TX-100 / ANI emulsion;

[0037] (2) Weigh 1-10g of ammonium persulfate (APS) and dissolve it in 1-100mL of distilled water;

[0038] (3) Pour the prepared TX-100 / ANI emulsion into a three-necked flask, add wood samples, start the stirring device, and keep the temperature at a moderate speed (1-5°C) (cold water bath), and insert a thermometer into the left port , monitor the temperature of the reaction at any time, and install a dropping funnel at the right port;

[0039] (4) Put the prepared APS solution into the droppi...

Embodiment 2

[0043] Doping with sodium lauryl sulfate to prepare polyaniline and pour it into wood

[0044] (1) Take 1-10g of sodium lauryl sulfate, slowly pour it into 1-100mL of 0-1M HCl solution under stirring, and stir to obtain the aqueous phase;

[0045] (2) Measure 1-100mL of aniline, and slowly add it into the above-mentioned sodium dodecylsulfonate hydrochloric acid solution under stirring; then add 1-100mL of a mixture of n-hexanol and n-hexane (the volume of n-hexanol and n-hexane The ratio is 1-10:1-5), after the addition is complete, stir first, then vibrate in ultrasonic waves to obtain a transparent microemulsion;

[0046] (3) Weigh 1-10g of ammonium persulfate (APS) and dissolve it in 1-100mL of distilled water;

[0047] (4) Pour the prepared transparent emulsion into a three-neck flask, add wood samples, start the stirring device, keep the temperature low (1-10°C) (cold water bath), insert a thermometer in the left port, and monitor the reaction temperature at any time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com