Preparation method of starch adhesive for papermaking coating, its product, and application of product

A technology of starch glue and starch, which is applied in coating, papermaking, paper coating, etc., can solve the problems of restricted application range, slow drying speed, poor water resistance, etc., and achieve the effects of easy operation, improved adhesion, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

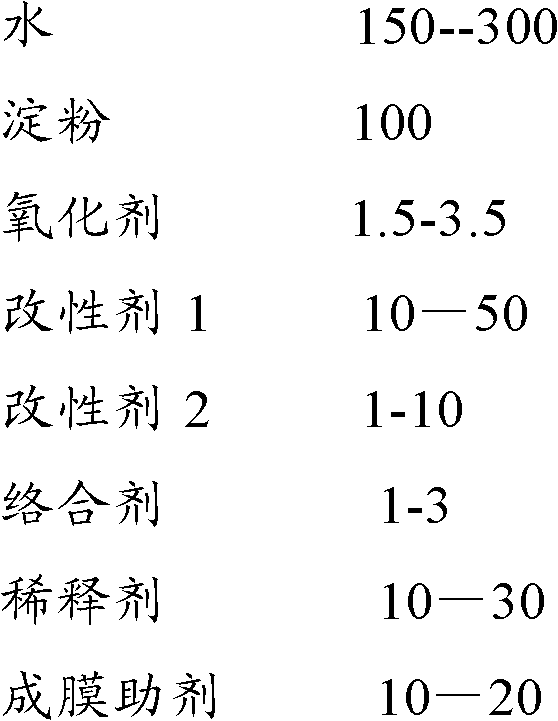

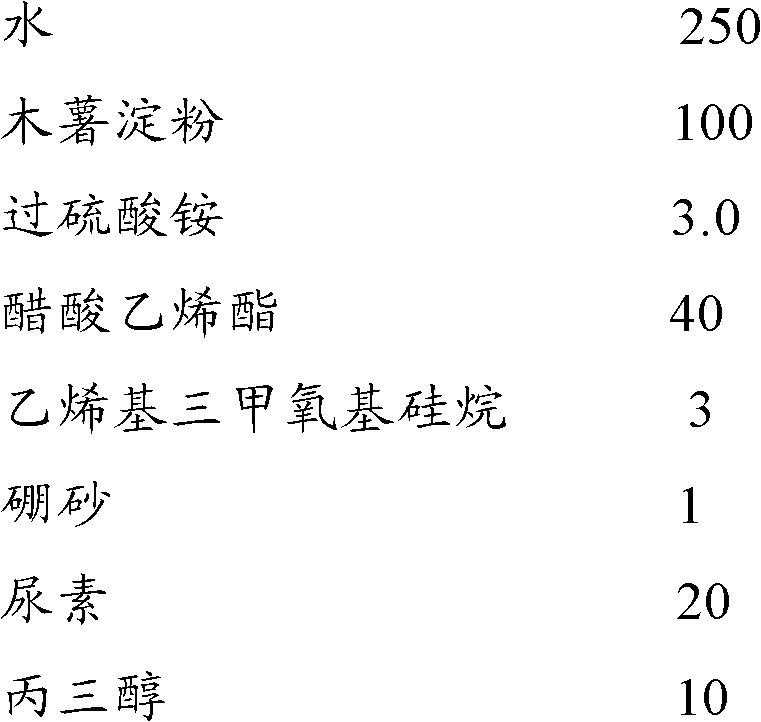

[0028] The weight of each material used is as follows (g):

[0029]

[0030] Process method: add citric acid to 35% cassava starch milk, adjust pH=2-3. Ammonium persulfate solution was added under stirring, the temperature was raised to 60°C, and the oxidation reaction was carried out for 1 hour. Adjust PH=4, add vinyl acetate and the remaining ammonium persulfate slowly at the same time, finish adding in 30 minutes, react at 75°C for 2 hours, adjust PH=7, add vinyltrimethoxysilane slowly at a uniform speed, finish adding in 10 minutes, then slowly add 5 % borax aqueous solution, keep the temperature at 80°C for 30min, cool down to 50°C, add urea and glycerol, stir for 20min, cool down to room temperature, discharge, and pack.

Embodiment 2

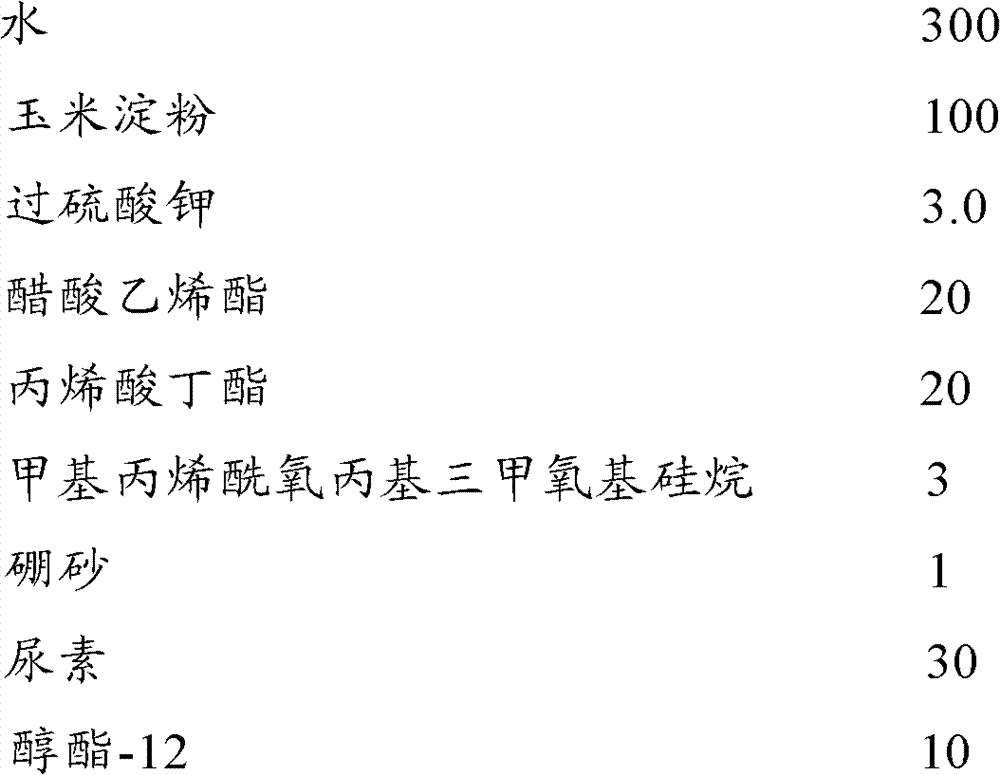

[0032] The weight of each material used is as follows (g):

[0033]

[0034] Process method: add hydrochloric acid to 30% cornstarch milk, adjust pH=2-3. Potassium persulfate solution was added under stirring, the temperature was raised to 60°C, and the oxidation reaction was carried out for 1 hour. Adjust PH=4, slowly add vinyl acetate, butyl acrylate and the remaining potassium persulfate at the same time, finish adding in 30 minutes, react at 75°C for 2 hours, adjust PH=7, add methacryloxypropyltrimethoxysilane slowly at a uniform speed After adding 10 minutes, slowly add 5% borax aqueous solution, keep the temperature at 80°C for 30 minutes, cool down to 50°C, add urea, alcohol ester-12, defoamer and fungicide, stir for 20 minutes, cool to room temperature, discharge, and pack.

Embodiment 3

[0036] The weight of each material used is as follows (g):

[0037]

[0038] Process method: add hydrochloric acid to cornstarch milk, adjust pH=2-3. Potassium persulfate solution was added under stirring, the temperature was raised to 60°C, and the oxidation reaction was carried out for 1.5 hours. Adjust PH=4, add vinyl acetate, butyl acrylate and the remaining potassium persulfate slowly at the same time, finish adding in 30 minutes, react at 70°C for 3 hours, adjust PH=7, add waterproof 3# slowly at a uniform speed, finish adding in 10 minutes, then slowly add 5% borax aqueous solution, keep the temperature at 80°C for 30 minutes, cool down to 50°C, add urea and alcohol ester-12, stir for 20 minutes, cool down to room temperature, discharge, and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com