Piling method of spiral steel pile

A technology of spiral steel and pile driver, which is applied to drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc. It can solve the problems of high labor cost, reduced strength of steel piles, and personnel injuries, and achieves wide application range and high efficiency. Pile driving speed, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

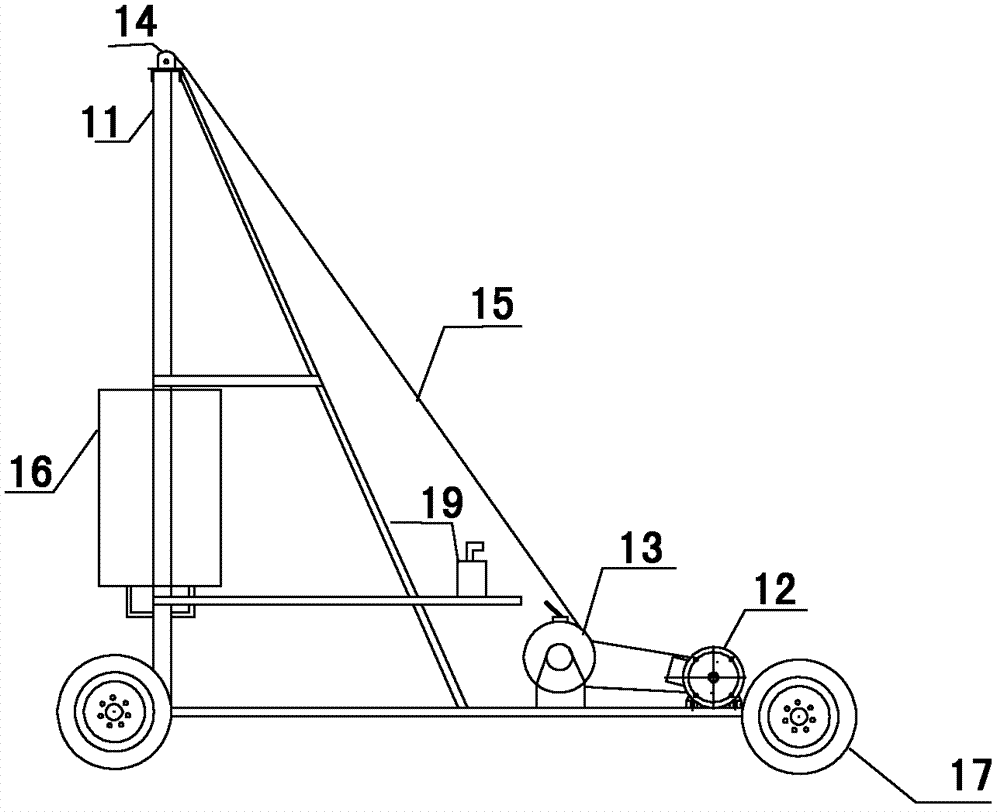

[0025] The piling method of the spiral steel pile of the present invention is to punch out a deep hole equivalent to the buried depth of the spiral steel pile with a hole puncher 1, and then screw the spiral steel pile into the above-mentioned deep hole with a pile placing machine 2 . Since the bottom of the drilling machine and the pile driver are provided with wheels, they can move within a certain range so as to drive multiple spiral steel piles within a certain range. According to the different terrain and geological conditions, two guide rails can also be prepared, and the drilling machine or pile laying machine can be erected on the guide rails to perform operations and move on the guide rails.

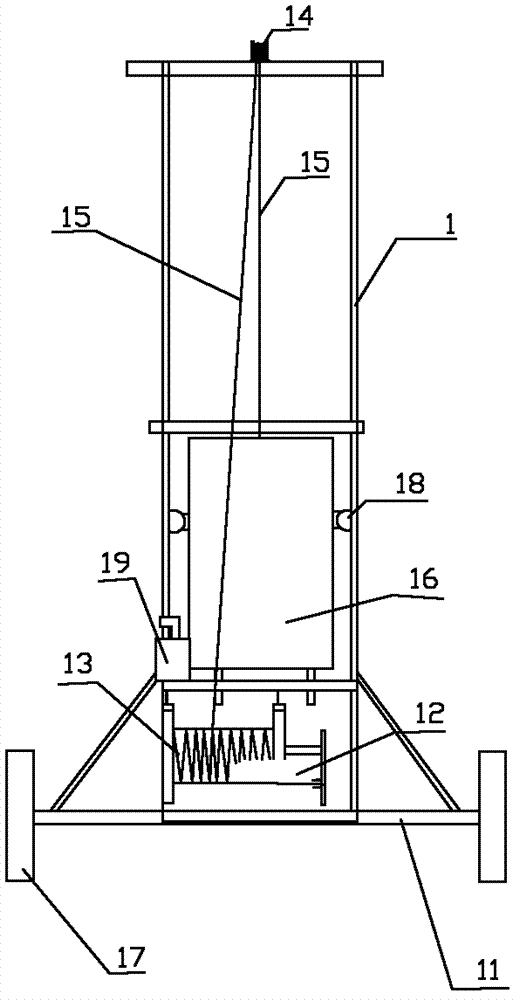

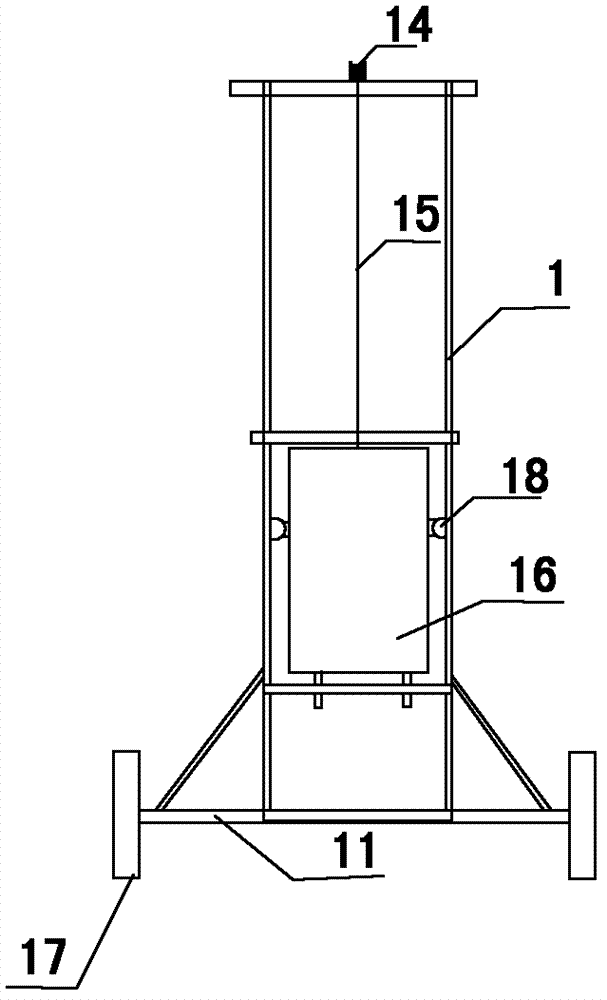

[0026] see Figure 1 to Figure 4 , punching machine 1 among the present invention comprises pedestal 11, motor 12, hoist 13, pulley 14, stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com