Resonance transmission rod for connecting sensor in acoustic emission detection

An acoustic emission sensor and acoustic emission detection technology, which is applied in the direction of material analysis, instruments, and measurement devices using acoustic emission technology, can solve the problems of distortion, large error in detection value, and attenuation of acoustic emission signal conduction, and achieve the detection value. The effect of small error, removal of signal interference, and removal of environmental noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

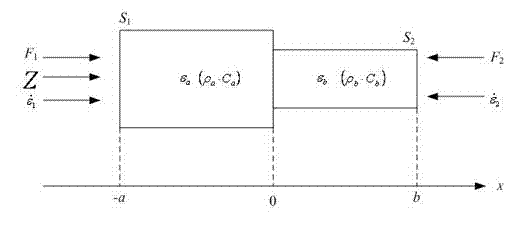

[0083] The acoustic emission signal that occurs when the lead is broken is typical, and it is relatively easy to obtain the signal, and it is similar to the acoustic emission signal that occurs when the solid material is broken and damaged. The lead broken signal will be used as the acoustic emission source for the verification test. Research shows that the center frequency of the acoustic emission signal from lead breaking is 80KHz, so the resonant natural frequency of the conduction rod designed below is 80KHz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com