High-power LD pumping thulium laser module

A laser module and high-power technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of laser reliability reduction, inability to prevent, and reduce laser efficiency, so as to achieve reliable operation, avoid sudden damage, and operate reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

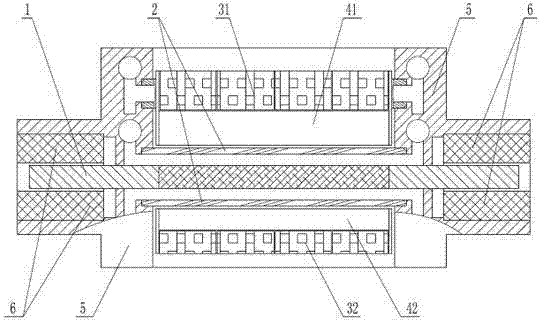

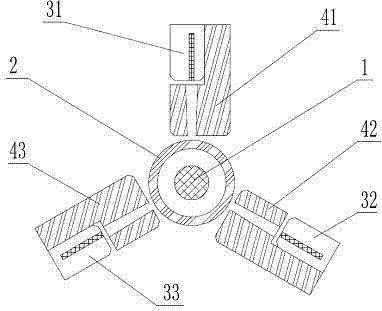

[0020] Such as Figure 1~2 As shown, the LD-pumped high-power thulium laser module of the present invention includes a laser crystal rod 1, a quartz sleeve 2, three sets of LD arrays 31, 32, and 33, three sets of light guide structures 41, 42, and 43, a support structure 5, and a crystal End heating sleeve 6 . The two ends of the quartz sleeve 2 are pressed and sealed through the sealing ring and the sleeve connection hole of the supporting structure. The outer surface of the quartz sleeve 2 is plated with silver reflective film, and the 1mm wide optical slits are uniformly distributed at 120 degrees around the axial centerline. Laser crystal rod 1 adopts a Tm:YAG bonded crystal rod with a diameter of 5mm. The part to be pumped is a doped crystal, and the part installed at both ends and heated on the surface is a non-doped crystal. The length is 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com