Plant fiber-ceramsite compound heat retaining building block

A plant fiber, composite thermal insulation technology, applied in the field of thermal insulation blocks, can solve the problems of unsatisfactory block strength, poor heat reflection ability of thermal insulation materials, general thermal insulation effect, etc., to improve thermal insulation effect, reduce total cost, The effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

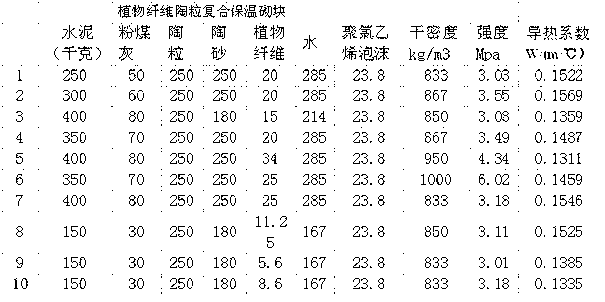

[0006] The material fiber ceramsite composite thermal insulation block provided by the invention includes cement, fly ash, ceramsite, pottery sand, plant fiber, water and polyvinyl chloride foam, and the mass ratio of the above materials is cement 100-400, fly ash 30 -80, ceramsite 250, pottery sand 180 or 250, plant fiber 5.6-34, water 167-285, polyvinyl chloride foam 22-25, wherein water is the water consumption when mixing, polyvinyl chloride foam in the present invention is not Using the method of mixing with other materials, it is inserted directly into the hole of the block after the block is formed. The above materials can be selected within a range, and the plant fiber is rice husk or straw or wheat straw fiber, and the effect of rice husk is the best. After the rice husk is added to the block, the multi-layer rice husk can have a better heat reflection effect after being superimposed. Among the above materials, the strength grade of cement is 42.5, the fly ash is gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com