Cold-resistant EPR (Ethylene-Propylene Rubber) insulating rubber eraser used on wind power generation flexible cable

A kind of flexible cable and cold-resistant technology, applied in the direction of organic insulators, rubber insulators, etc., can solve the problems of low temperature tensile strength of -40 °C, poor cold-resistant performance of ethylene-propylene rubber, etc., to improve cold-resistant performance, good cold-resistant performance, Good extrusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

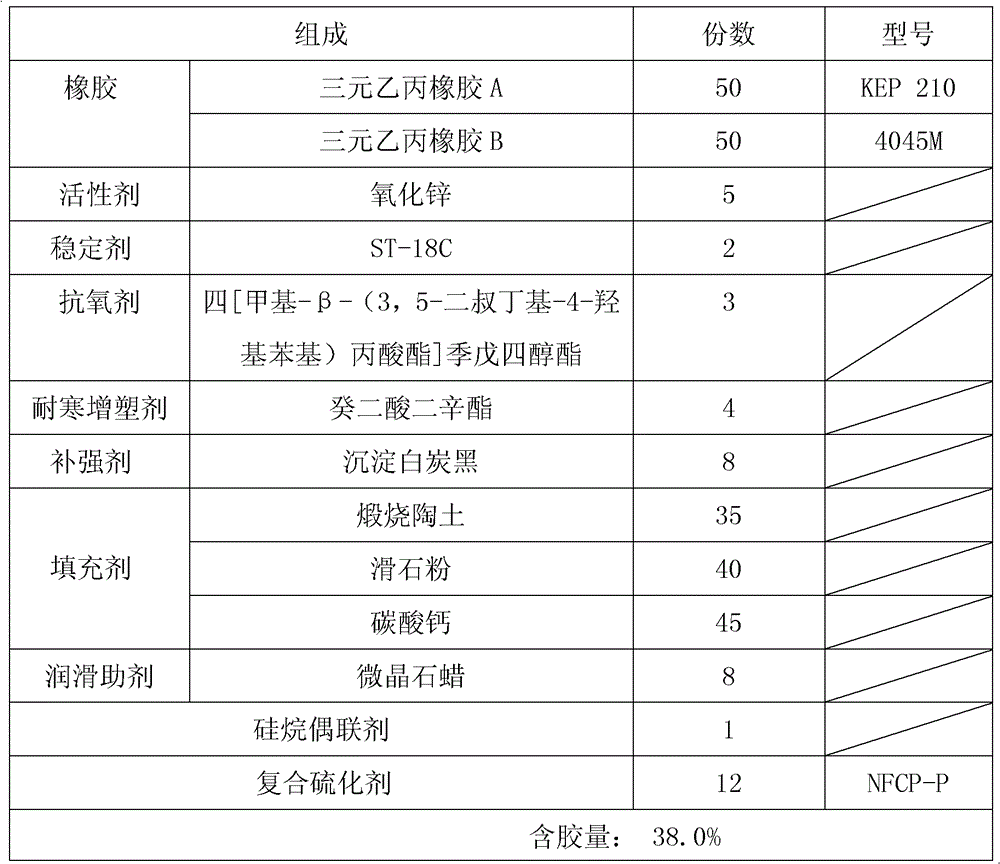

[0032] The composition of the EPR insulating rubber of the present embodiment, the proportioning number of parts and the model are shown in Table 1:

[0033] Table I

[0034]

[0035] In this example:

[0036] Properties of mixed film:

[0037] Mooney viscosity M(1+4) at 100°C is: 35.0Mv

[0038] The maximum torque MH at 170℃*15min on the rheometer is: 3.2N.m

[0039] The process scorch time t10 at 170℃*15min on the rheometer is: 1.0min

[0040] The process positive vulcanization time t90 at 170℃*15min on the rheometer is: 9.0min

[0041] Volume resistivity at 20°C: 5.6*10 14 Ω.m

[0042] Tensile strength: 7.5N / mm 2

[0043] Elongation: 380%

[0044] Specific gravity: 1.42g / cm 3

[0045] -40℃×4 hours cold resistance tensile elongation: 120%

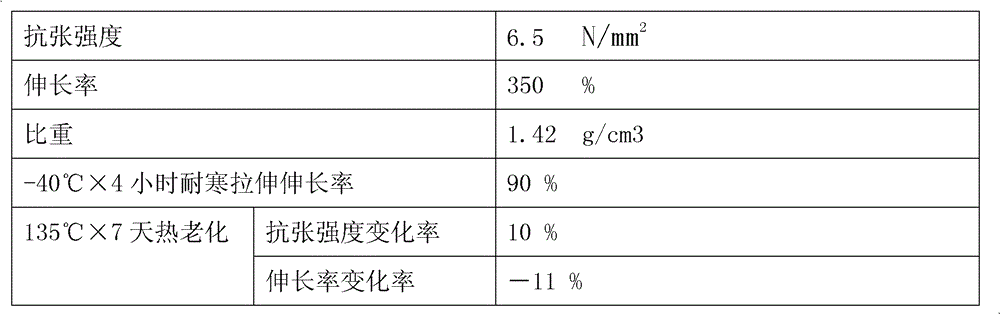

[0046] The performance of the finished product EPR insulating rubber produced according to the present embodiment is shown in Table 2:

[0047] Table II

[0048]

Embodiment 2

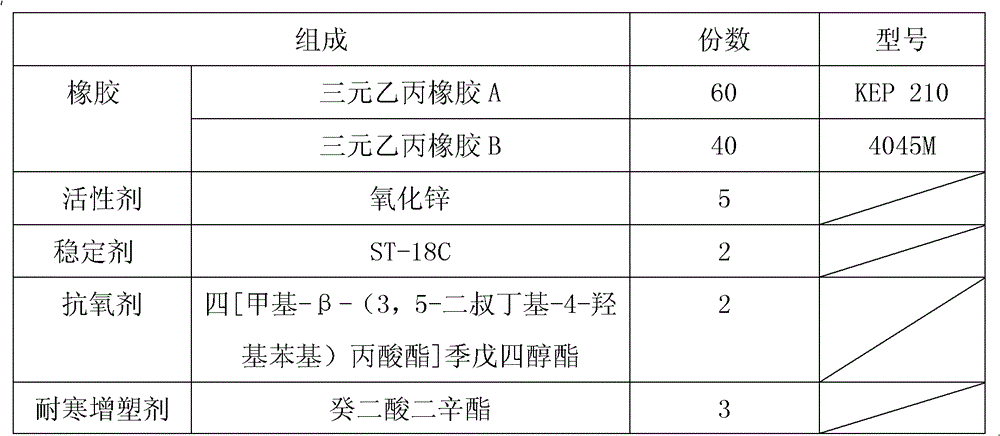

[0050] The composition of the EPR insulating rubber of the present embodiment, the proportioning number of parts and the model are shown in Table 3:

[0051] Table three

[0052]

[0053]

[0054] In this example:

[0055] Performance of mixed film:

[0056] Mooney viscosity M(1+4) at 100°C is: 32.0Mv

[0057] The maximum torque MH at 170℃*15min on the rheometer is: 3.3N.m

[0058] The process scorch time t10 at 170℃*15min on the rheometer is: 0.9min

[0059] The process positive vulcanization time t90 at 170℃*15min on the rheometer is: 8.2min

[0060] Volume resistivity at 20°C: 6.5*10 14 Ω.m

[0061] Tensile strength: 8.0N / mm 2

[0062] Elongation: 350%

[0063] Specific gravity: 1.40g / cm 3

[0064] -40℃×4 hours cold resistance tensile elongation: 90%

[0065] The performance of the finished product EPR insulating rubber produced according to the present embodiment is shown in Table 4:

[0066] Table four

[0067]

Embodiment 3

[0069] The composition of the EPR insulating rubber of the present embodiment, the proportioning number of parts and the model are shown in Table five:

[0070] Table five

[0071]

[0072] In this example:

[0073] Properties of mixed film:

[0074] Mooney viscosity M(1+4) at 100°C is: 33.5Mv

[0075] The maximum torque MH at 170℃*15min on the rheometer is: 3.0N.m

[0076] The process scorch time t10 at 170℃*15min on the sulfur rheometer is: 1.1min

[0077] The process positive vulcanization time t90 at 170℃*15min on the rheometer is: 10.0min

[0078] Volume resistivity at 20°C: 2.2*10 14 Ω.m

[0079] Tensile strength: 7.0N / mm 2

[0080] Elongation: 340%

[0081] Specific gravity: 1.41g / cm 3

[0082] -40℃×4 hours cold resistance tensile elongation: 135%

[0083] The performance of the finished product EPR insulating rubber produced according to the present embodiment is shown in Table six:

[0084] Table six

[0085]

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com