Material sorting device

A technology for sorting devices and materials, which is applied in the direction of biofuels, special dry distillation, and the manufacture of combustible gases, etc. It can solve the problems of limited carbonization quality, simple structure, and insufficient straw combustion, etc., to ensure carbonization quality and production efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A specific embodiment is enumerated below in conjunction with the accompanying drawings to further illustrate the invention.

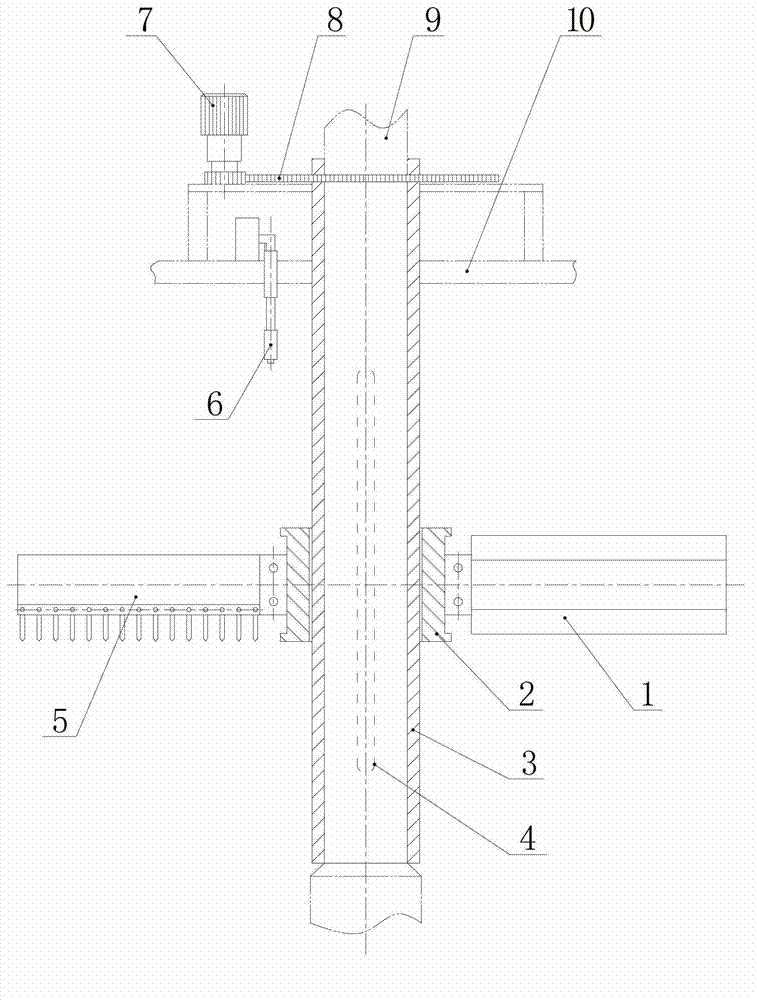

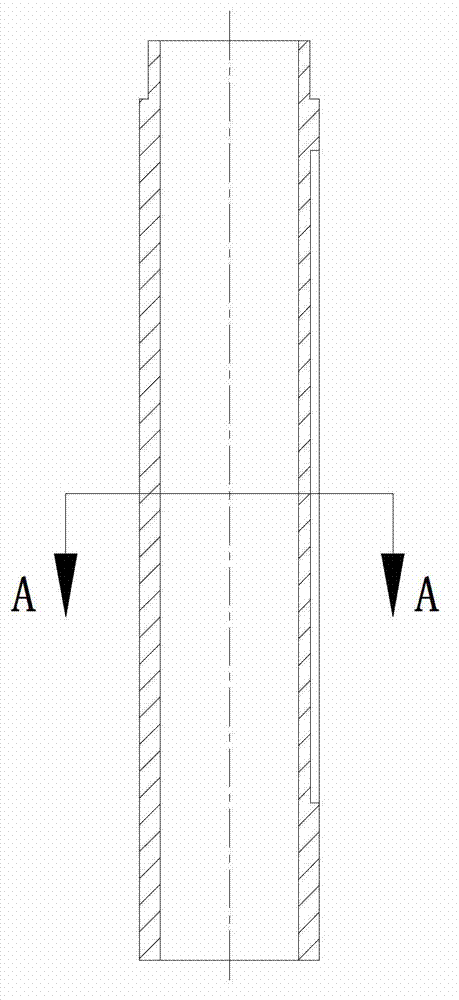

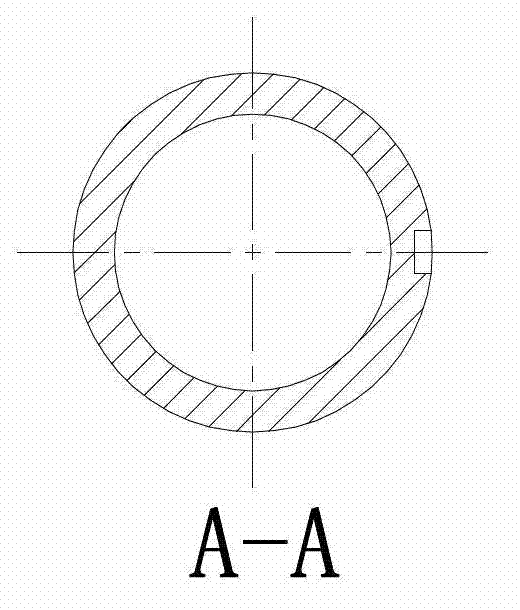

[0021] In this example, if Figure 1-Figure 5 As shown, a material sorting device includes a rotating sleeve 3, a lifting sleeve 2, a furnace rake 5, a regular hexagonal column 1 and a transmission device 8; the outer peripheral surface of the rotating sleeve 3 is provided with a first keyway, and the first keyway matches There is a flat key 4, and the rotating sleeve 3 is set on a fixed shaft 9; the inner peripheral surface of the lifting sleeve 2 is provided with a second keyway matching the flat key 4, and the lifting sleeve 2 is set on the rotating sleeve 3 through the key; The rake 5 is fixed on the outer peripheral surface of the lifting sleeve 2, and the action surface of the rake teeth is a horizontal plane; the regular hexagonal prism 1 is fixed on the outer peripheral surface of the lifting sleeve 2, and the central axis of the regular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com