Airfoil blade disk turbine mixer used in fermentation tank

A disc turbine stirring and fermenter technology, which is applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc. , Insufficient airflow control ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

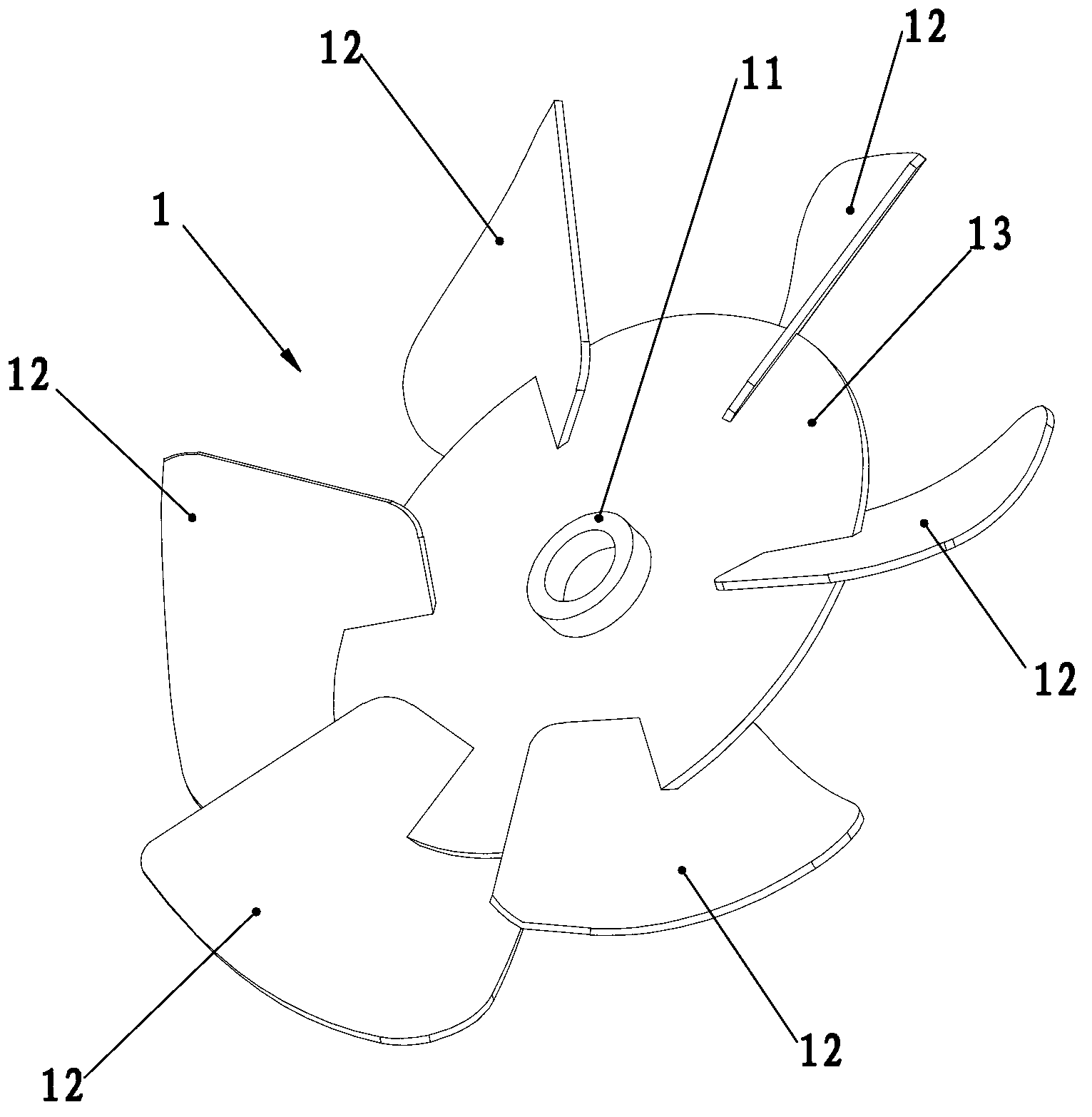

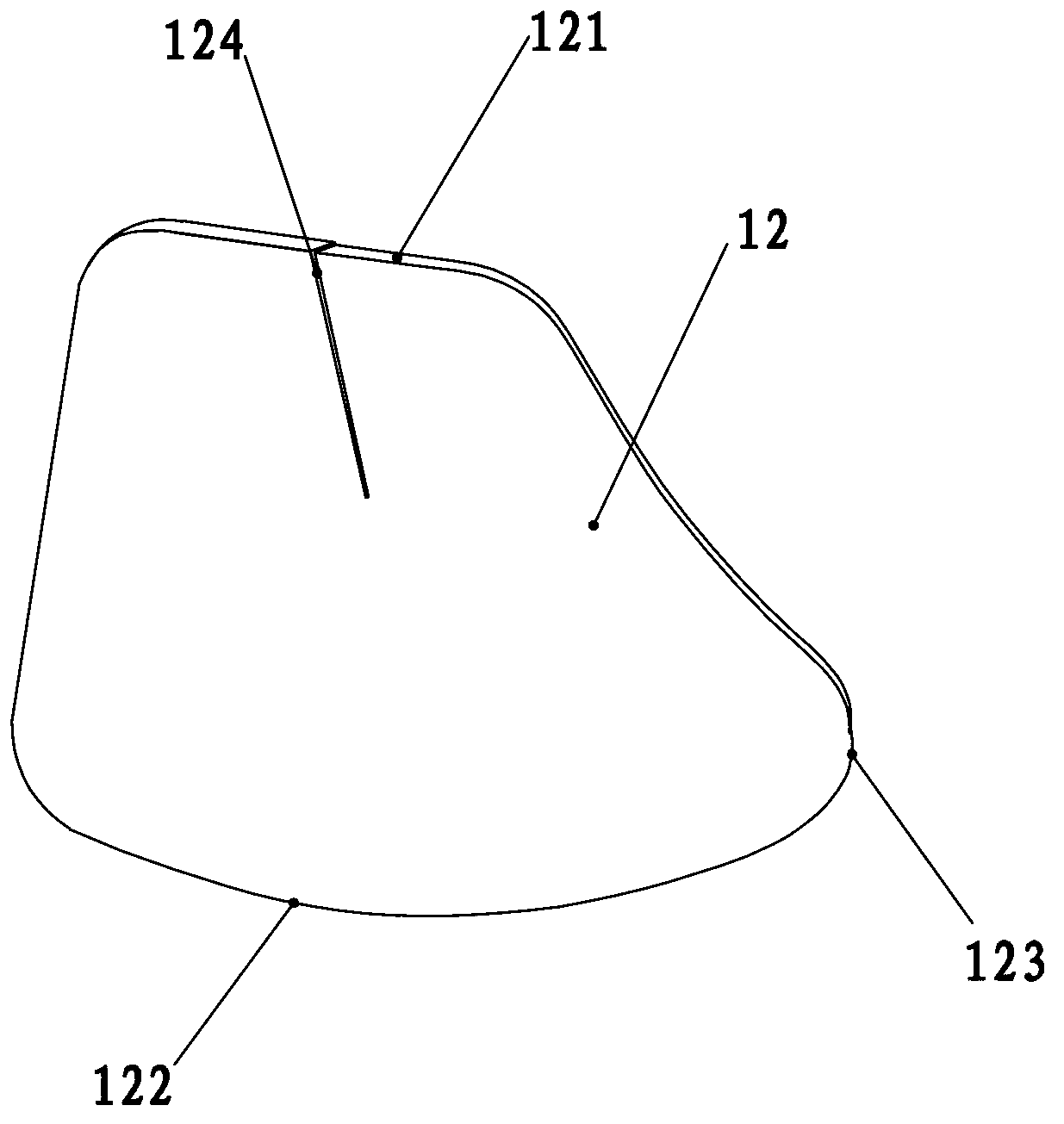

[0015] Such as figure 1 , figure 2 The illustrated aerofoil disc turbine agitator for a fermenter includes an agitator body 1, and the agitator body 1 includes a hub 11 and agitating blades 12 uniformly distributed along the circumference of the hub 11, between the agitating blade 12 and the hub 11 There is an annular airflow guiding plate body 13 therebetween, and the airflow guiding plate 13 is fixedly connected with the hub 11 and the stirring blade 12; the stirring blade 12 is installed on the airflow guiding plate body 13 in an oblique shape. By setting the air flow guide plate 13 between the hub 11 and the stirring blade 12, during use, the rising air flow will be blocked by the air flow guide plate 13, and then translate to the stirring blade 12 along its air flow guide plate 13, and the stirring blade 12 Stir it to disperse the airflow; this setting can control the rising airflow, effectively prevent the airflow from directly passing through the agitator body 1 witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com