Preparation method of low-cost and high-performance lithium iron phosphate

A lithium iron phosphate, high-performance technology, applied in the field of preparation of low-cost and high-performance lithium iron phosphate, can solve the problems of high cost, influence on the price of lithium batteries, and influence on the popularization of electric vehicles, so as to reduce the cost of raw materials, reduce the cost of sintering, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preparation method of a kind of low-cost high-performance lithium iron phosphate of the present embodiment, concrete experiment comprises the following steps:

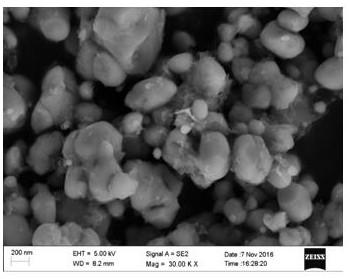

[0022] (1) The iron source and phosphorus source selected in this experiment are anhydrous ferric orthophosphate (the actual Fe / P is 0.97±0.1), and the shape is a spherical particle. First, it is crushed efficiently in a high-energy pulverizer, and the particle size is controlled by D50 after crushing. Below 1.5um; lithium source is industrial grade lithium carbonate (purity ≥ 99%).

[0023] (2) According to the molar ratio (1.01-1.03): 1:1, weigh a certain amount of lithium source, iron source, phosphorus source, mix the titanium source with a molar ratio (0.01-0.02), and then add the mass fraction (4- 10)% carbon source, the actual formula adopted in this experiment is iron phosphate: 21.285Kg, lithium carbonate: 5.339Kg, titanium dioxide: 0.105Kg, anhydrous glucose: 2.25Kg, β-cyclodextrin: 1.175Kg, Nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com