NdFeB magnet grain boundary diffusion method

A grain boundary diffusion, NdFeB technology, applied in the direction of magnetic objects, magnetic materials, inductor/transformer/magnet manufacturing, etc., can solve the problems of surface state damage of magnets, reduction of magnet remanence, reduction of charging amount, etc., to achieve enhanced Penetrating ability, improving coercivity, preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

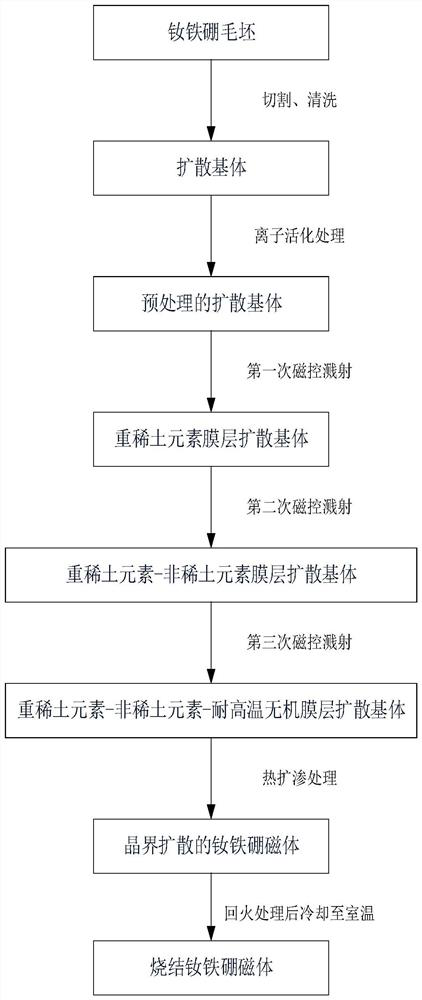

Method used

Image

Examples

Embodiment 1

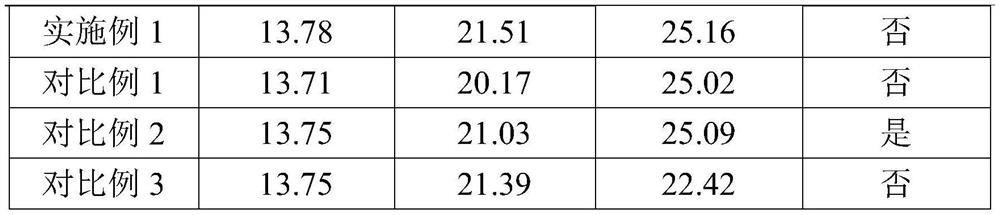

[0058] The sintered NdFeB magnet with the grade of N50M is selected as the diffusion matrix, and its size is 20*30*4mm. Dy was selected as the heavy rare earth element target, Al as the non-rare earth element target, and alumina as the inorganic target. Magnetron sputtering is used to deposit heavy rare earth Dy film, non-rare earth Al film, and aluminum oxide inorganic film on the surface of the diffusion substrate in sequence, followed by grain boundary diffusion.

[0059] Step 1: Preprocessing

[0060] Use degreaser to remove oil from the surface, then use 4 wt.% dilute nitric acid solution to clean the diffusion matrix for rust removal, use deionized water to ultrasonically clean the diffusion matrix, and dry it with a hair dryer for use. Evacuate the coating chamber of the coating equipment to 1x10 -4 Below Pa, high-purity argon gas was introduced, and the gas path was cleaned for 10 minutes. Put the pretreated diffusion substrate into the magnetron sputtering coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com