Novel material of piston of breaking hammer and manufacturing process of piston

A new type of material and breaking hammer technology, applied in the field of breaking hammers, can solve the problems of piston hitting end face depression, low core strength, low tensile strength, etc., and achieve the effect of low hardness, increased life and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

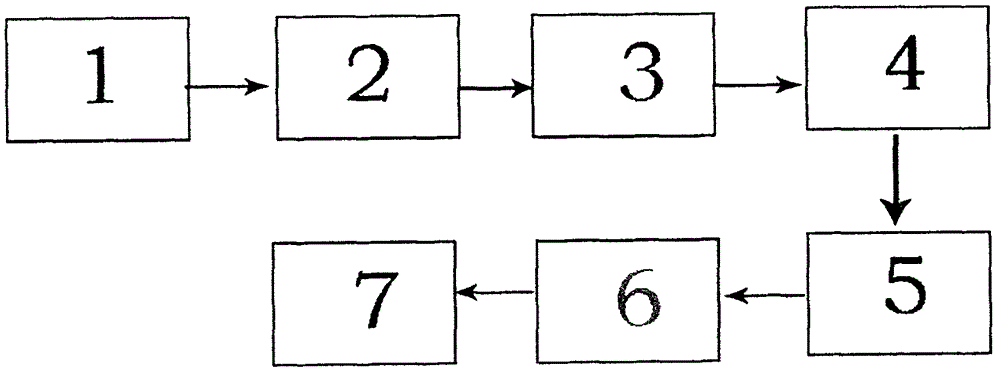

[0023] Embodiment: A preparation process for a breaker piston includes blank forging 1, normalizing and high temperature tempering 2, machining 3, carburizing and quenching 4, cryogenic treatment 5, low temperature tempering 6, and finishing 7. Rough forging 1 is to pour the new material of the broken hammer into the mold to form the blank of the broken hammer piston, and then change the shape and size of the blank under the action of external force; the broken hammer piston after rough forging is normalized and tempered at high temperature 2 stage, first heat to 500°C, hold for 10 minutes, cool in still air and then heat to 500-650°C, hold for 10 minutes, cool to room temperature, after normalizing and high temperature tempering for 2, there is almost no residual Austrian It provides a good basic structure for quenching, and the hardness of the workpiece after tempering is suitable for subsequent machining 3; machining 3 is cold working at room temperature to change the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com