Device and method for treating waste gas

A technology of exhaust gas post-treatment and equipment, which is applied in the direction of exhaust gas treatment, mechanical equipment, gas channels, etc., and can solve problems such as difficult combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

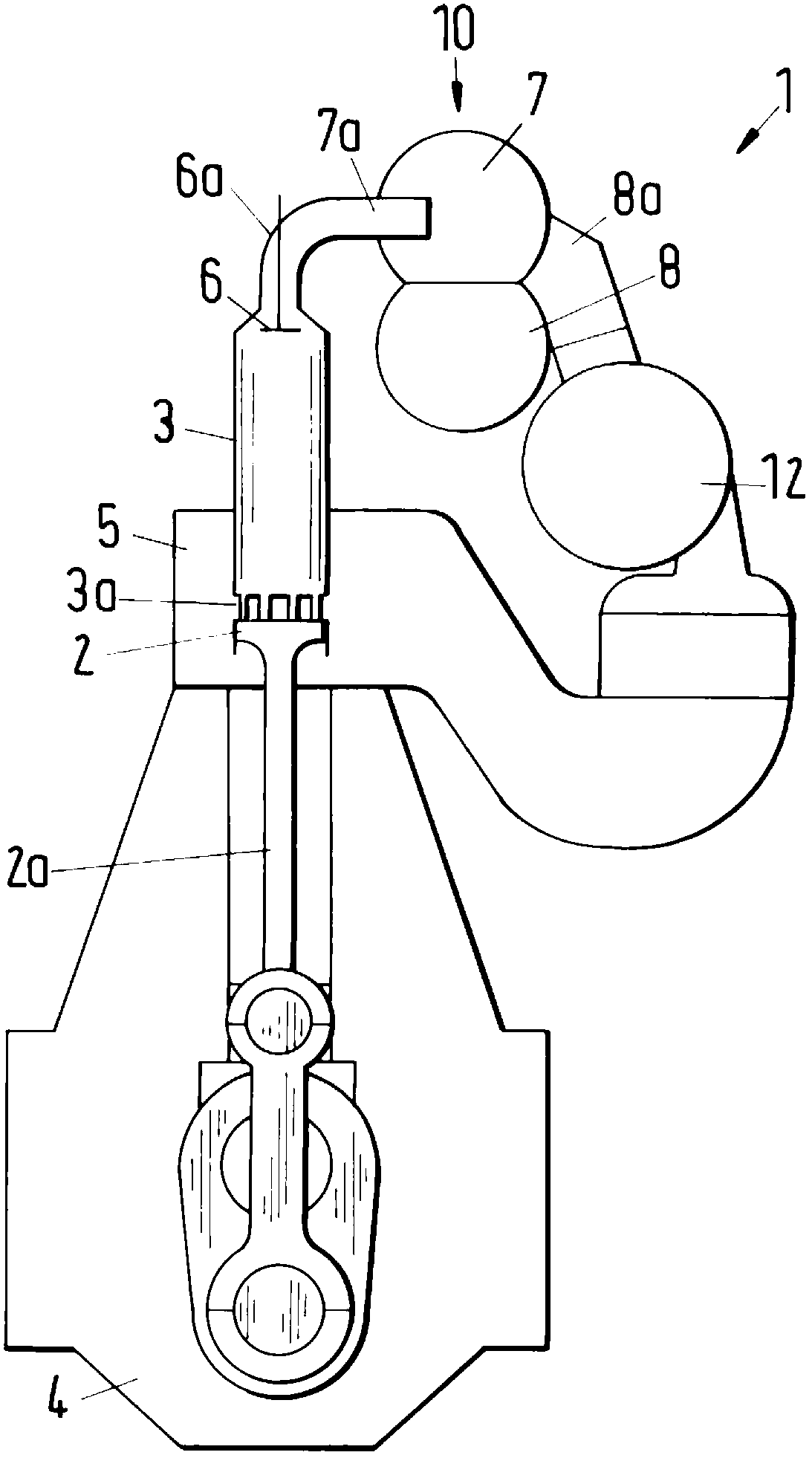

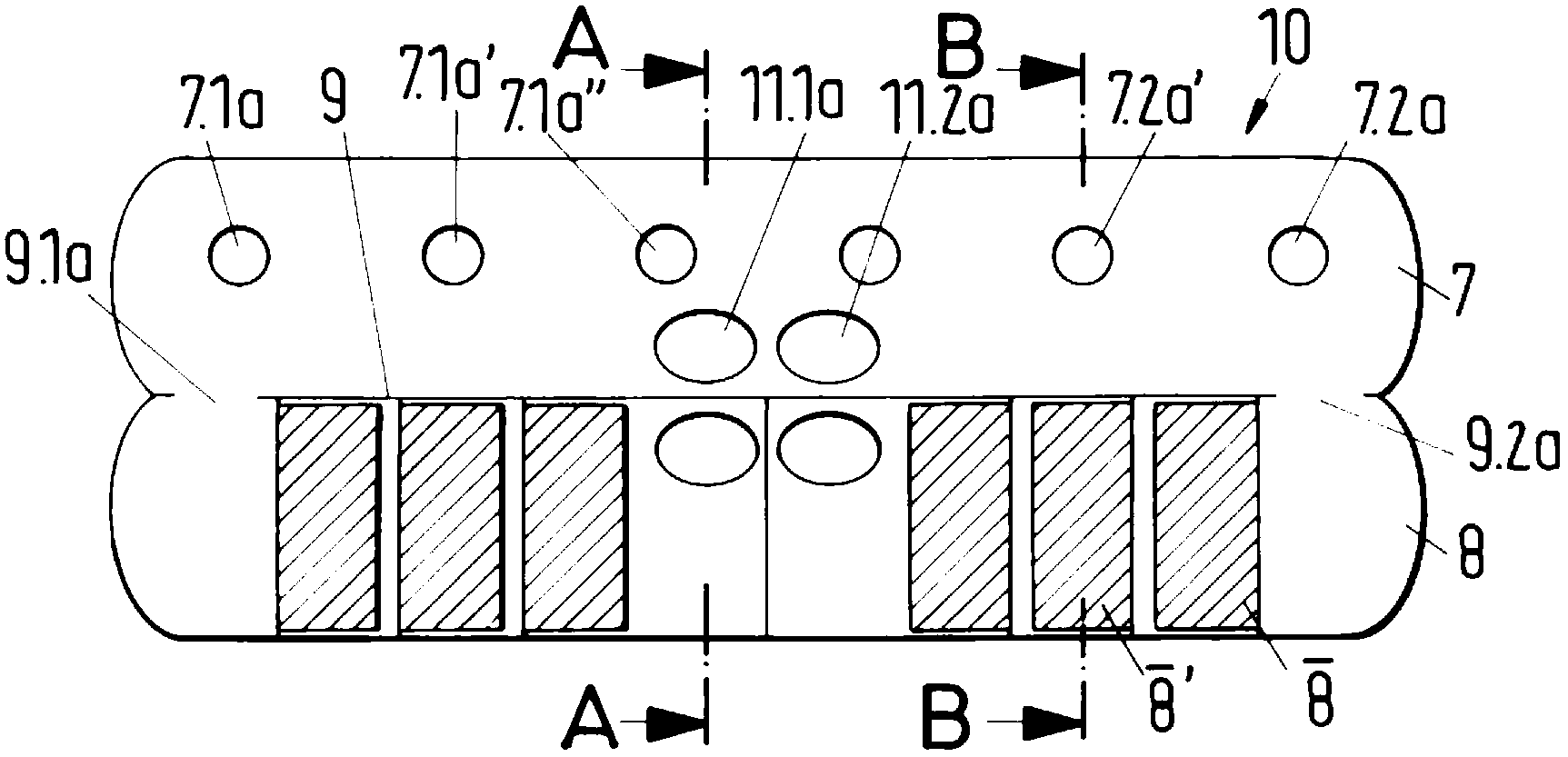

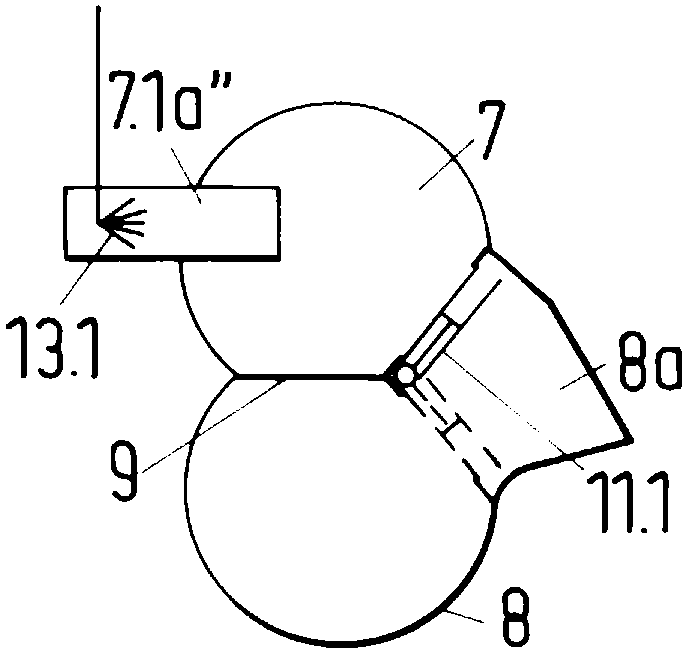

[0032] figure 1An embodiment of a large diesel engine 1 according to the invention is shown. Large diesel engines, especially large two-stroke diesel engines, such as are used in ships and power plants, generally comprise one or more of the following components: a crankshaft rotatably supported in a crankcase 4, at least one crosshead And at least one piston 2 arranged in a cylinder liner 3 in a movable manner. Typically, the piston 2 is connected in each case via a piston rod 2a to a crosshead, and the crosshead is connected in each case via a connecting rod to a crankshaft for driving said crankshaft. The cylinder liner 3 is usually terminated upwards by the cylinder head, so that a cylinder space (also called combustion space) emerges between the piston and the cylinder head.

[0033] In modern large-scale two-stroke diesel engines, direct-flow scavenging of the cylinder space is usually provided, that is, as soon as the piston 2 is located below the scavenging slit 3a, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com