Efficient thermal oxidation furnace for low afterburning-amount smoke constant-speed grading reaction

A technology of thermal oxidation furnace and graded reaction, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as limitation, and achieve the effects of reducing manufacturing costs, avoiding tempering, and improving the degree of sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

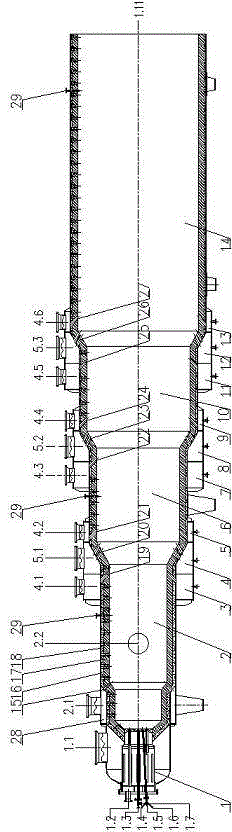

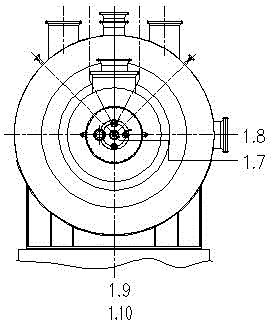

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as figure 1 , figure 2 As shown, a high-efficiency thermal oxidation furnace with low supplemental combustion flue gas constant velocity staged reaction, the thermal oxidation furnace includes a furnace body and a burner 1, and the burner 1 is arranged at the front end of the furnace body. The burner 1 has an independent combustion-supporting air inlet 1.1; the furnace body includes a combustion section 2 that uses high-calorific-value fuel and combustion-supporting air to generate high-temperature flue gas through peroxygen mixed combustion, and a combustion section for gradually thermally oxidizing and decomposing the exhaust gas. Multi-stage thermal oxidation section; in this embodiment, the thermal oxidation section is three-stage, that is, the primary thermal oxidation section 6, the secondary thermal oxidation section 10 and the third-stage thermal oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com