Method for solving copper conductor temperature by optical fiber temperature for photoelectric composite submarine cables

A submarine cable and photoelectric composite technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of consuming manpower and material resources, low accuracy of thermal performance parameters, etc., and achieve the effect of no damage and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

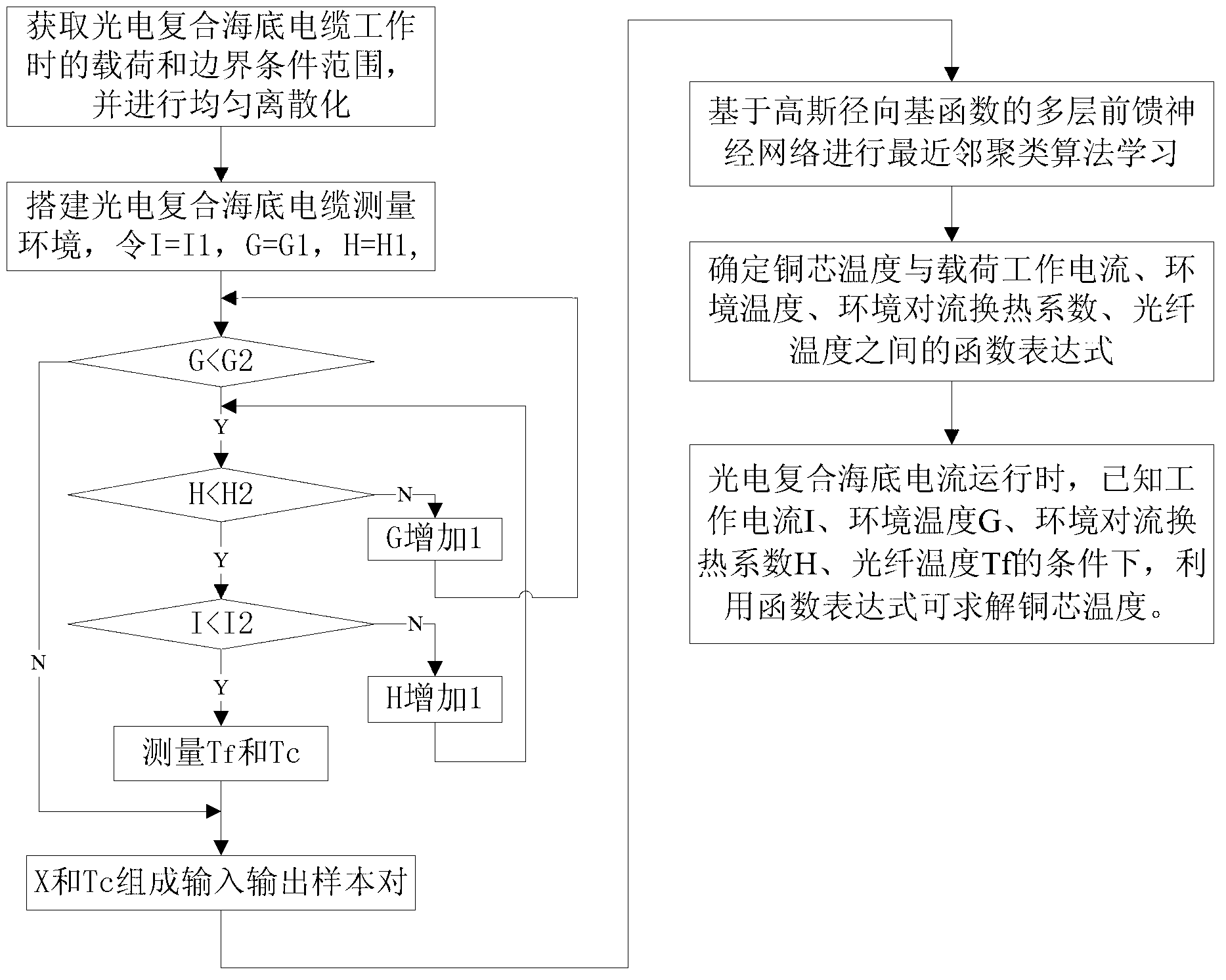

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

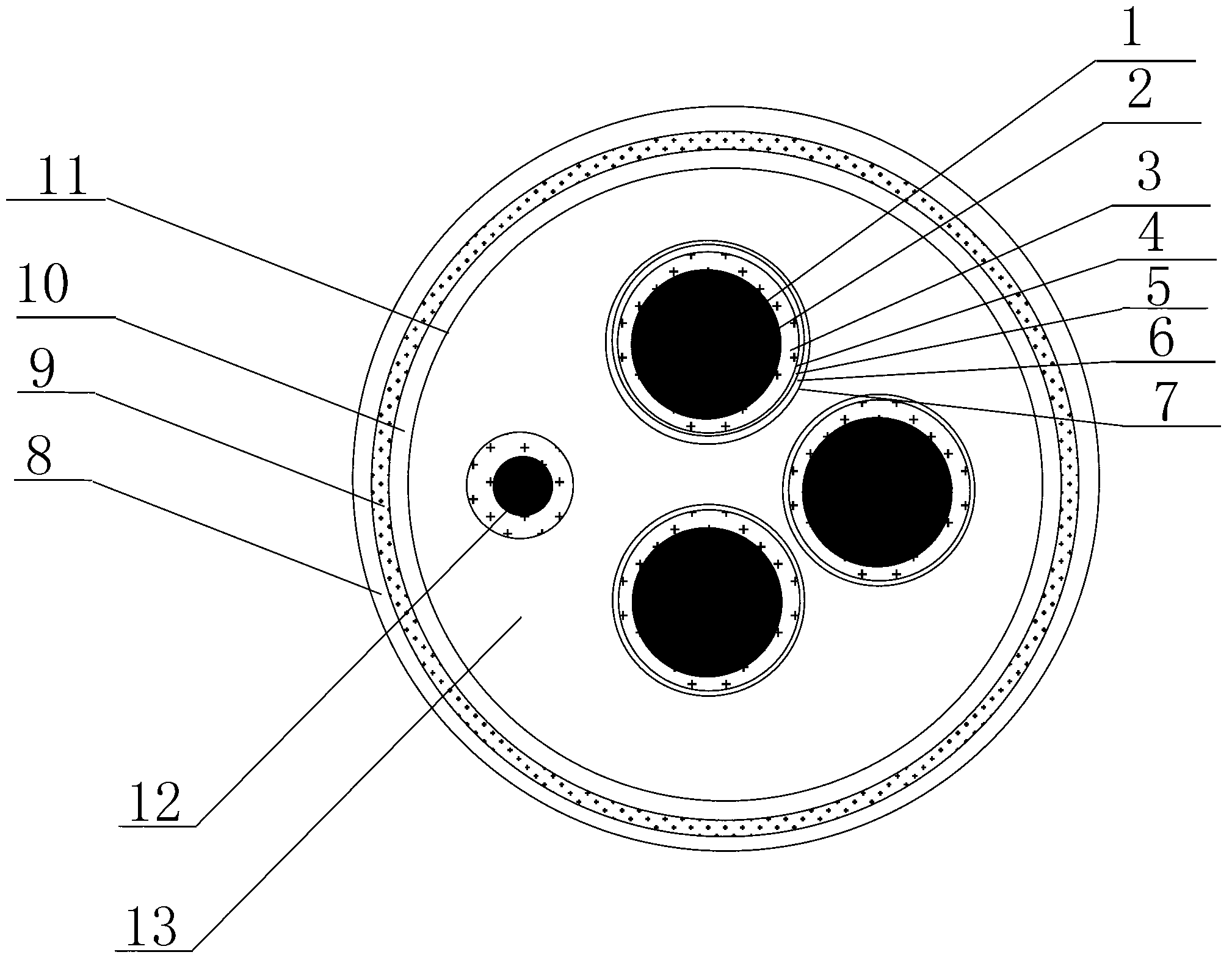

[0018] figure 1 It is a structural schematic diagram of a photoelectric composite submarine cable that needs to measure the copper core temperature in the present invention. Such as figure 1 Shown: A photoelectric composite submarine cable that needs to measure copper core temperature includes three water-blocking copper conductors 1, each water-blocking copper conductor 1 has a conductor shield 2 on its surface, and the outer layer of the conductor shield 2 has XLPE insulation 3, XLPE insulation 3 The outer layer of the insulating shield 4 is provided with an insulating shield 4, and the outer layer of the insulating shield 4 is provided with a semiconductor water-blocking layer 5, and the outer layer of the semiconductor water-blocking layer 5 is followed by an alloy lead sleeve 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com