Cathode-adjustable single anode magnetic control electron gun

A magnetron electron gun, adjustable technology, applied to the electron/ion gun of the transit time type electron tube, etc., can solve the problems of inability to adjust, the efficiency of the injection-wave interaction is reduced, and the initial speed of the electron is discretely increased, and the reduction is achieved. Equipment error and thermal deformation, excellent performance, and the effect of reducing discreteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

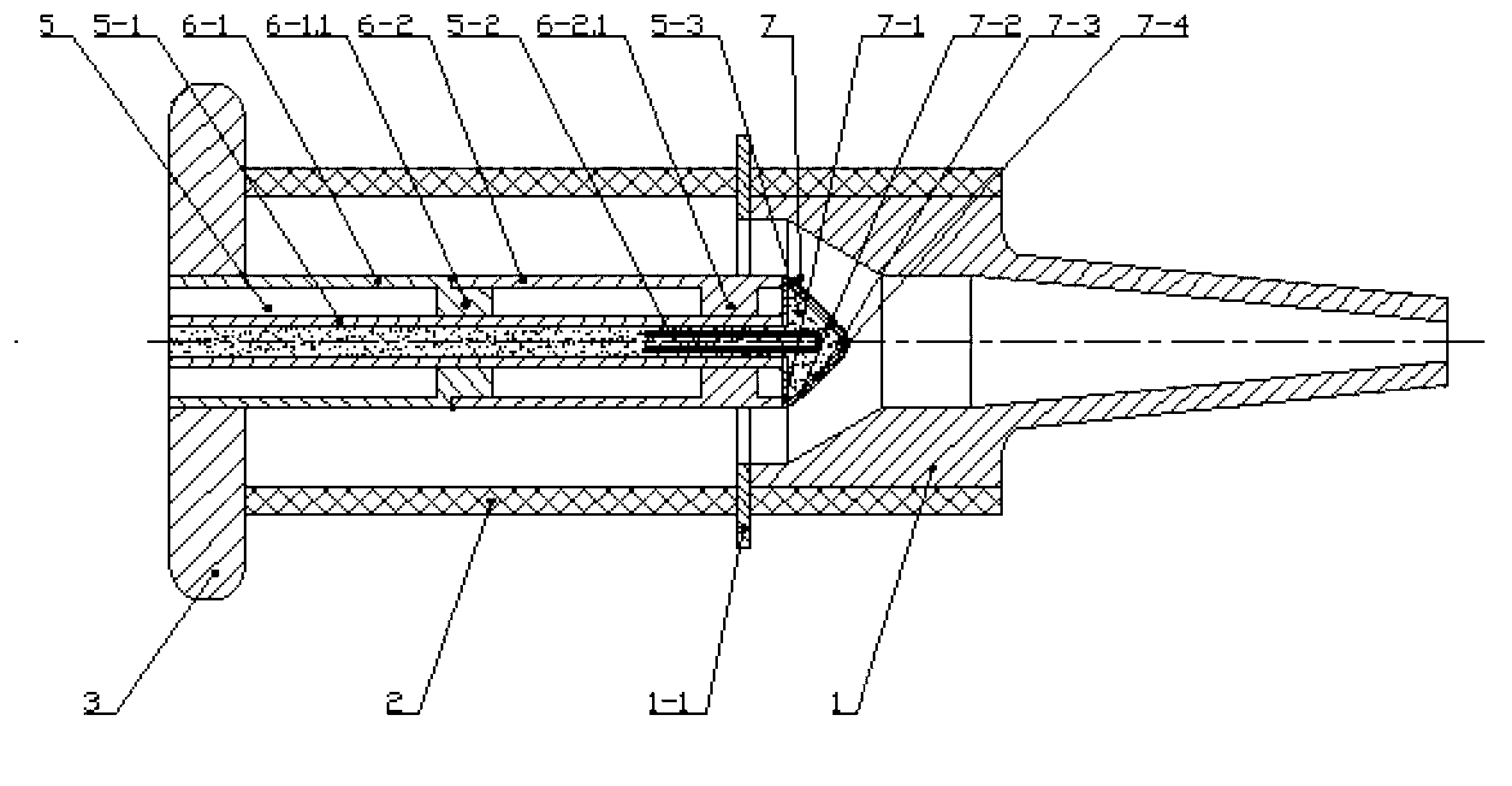

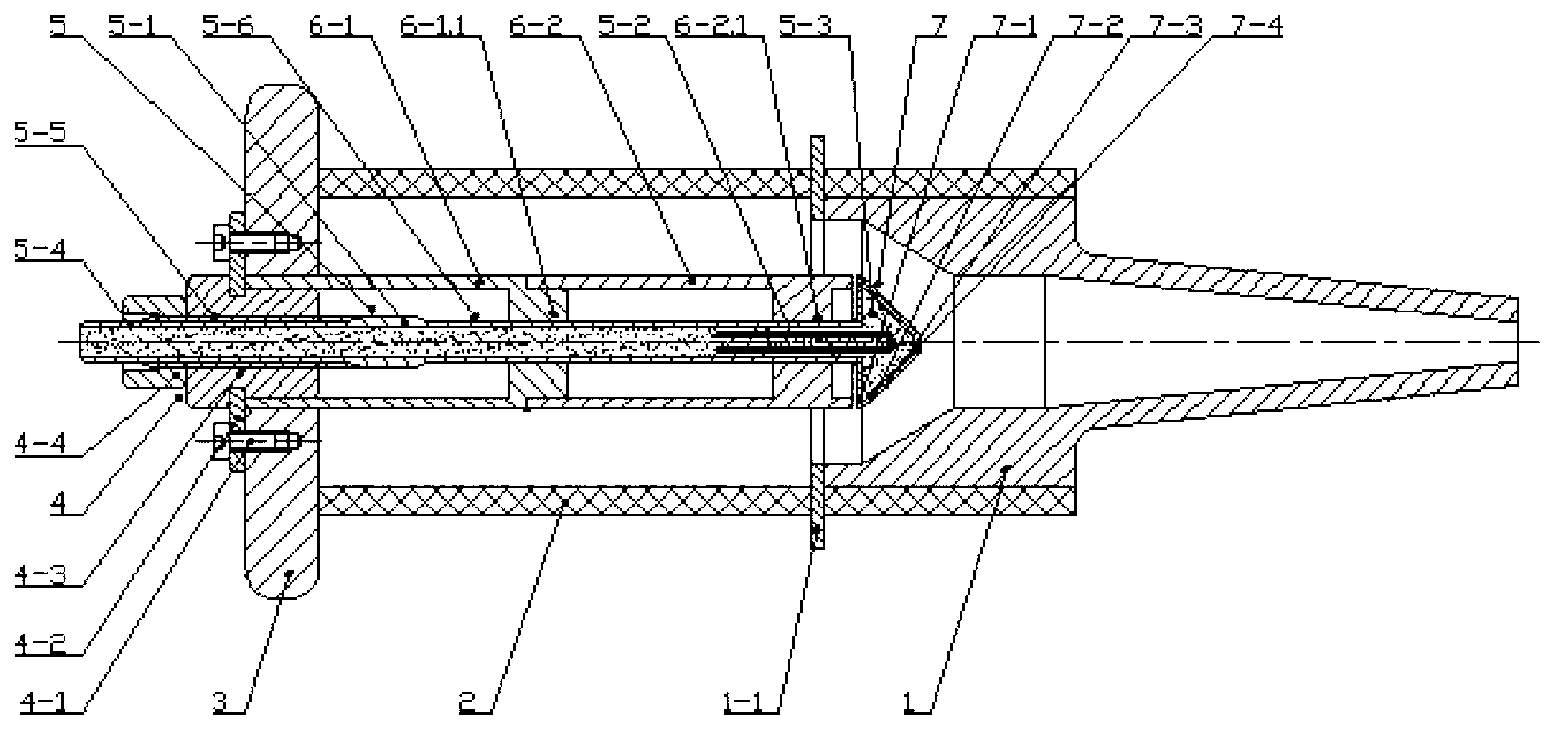

[0012] This embodiment: the total length is 283mm, the anode 1. The axial length is 136mm, the outer diameter of the rear part is Φ57mm, the diameter of the middle part is Φ26mm, the front length is 86mm, the inclination angle of the cone annulus at the rear part (covered on the cathode) is 32°, and the taper of the front part is 11 °, shell 2. outer diameter Φ68mm, length 150mm, wall thickness 5.5mm, base 3. outer diameter Φ102mm, thickness 15mm, center hole diameter Φ27mm; heating wire assembly 5: heating wire sleeve 5-1 length 152mm, outer Diameter Φ10mm, wall thickness 1.0mm, upper scale section 5-4 outer diameter Φ9.0mm (wall thickness 0.5mm), axial length 10mm, adjusting thread 5-5 adopts G10 fine tooth pipe thread, thread section length 45mm, The guide plane 5-6 in this embodiment is made of two arc-shaped cylinders with a symmetrical grinding height of 0.2mm on the upper and lower sleeves before the length of the thread section; the resistance of the heating wire 5-2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com