Rare earth-containing Y-type molecular sieve cracking catalyst and preparation method thereof

A cracking catalyst, molecular sieve technology, applied in the direction of molecular sieve catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of small total pore volume and specific surface area of cracking catalyst, poor wear resistance, etc., to reduce production costs and Effects of low pressure, coke yield and heavy oil yield, and good abrasion resistance for subsequent waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

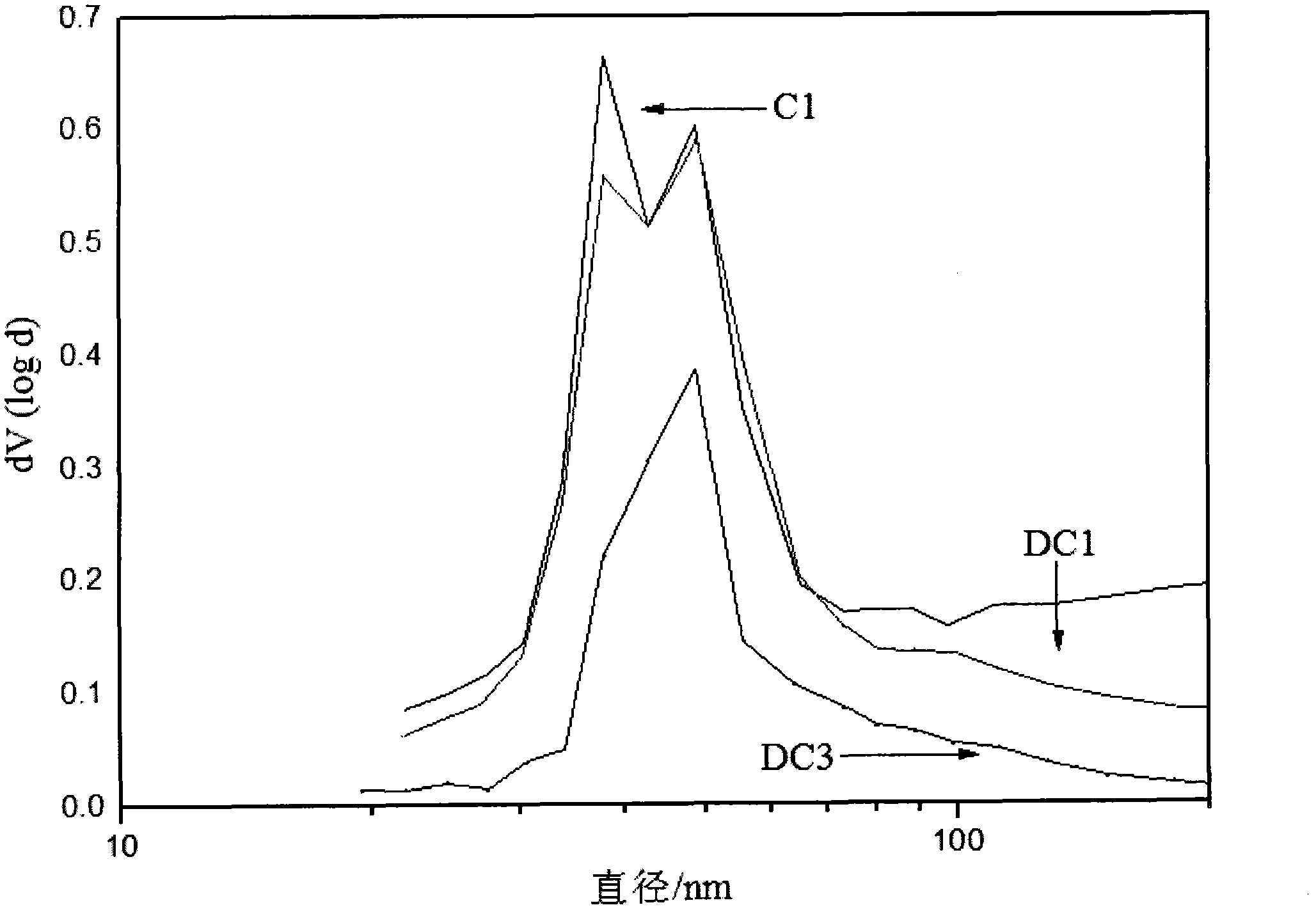

Image

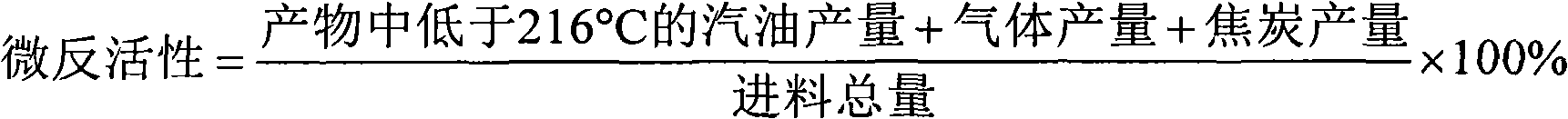

Examples

preparation example Construction

[0015] The preparation method of the Y-type molecular sieve cracking catalyst containing rare earth according to the present invention comprises the following steps:

[0016] (1) mixing the NaY molecular sieve without ion exchange with the substrate, beating and spray-drying to form a catalyst precursor;

[0017] (2) performing a first calcination on the catalyst precursor at a temperature of 200°C to less than 400°C, and performing ammonium ion exchange on the product obtained after the first calcination; and

[0018] (3) subjecting the product obtained after the ammonium ion exchange to at least one second roasting and at least one rare earth ion exchange, the rare earth ion exchange being performed after the second roasting;

[0019] The temperature of the ammonium ion exchange is higher than the temperature of the rare earth ion exchange, and the temperature of the ammonium ion exchange is 100-200°C; the temperature of the second calcination is higher than the temperature ...

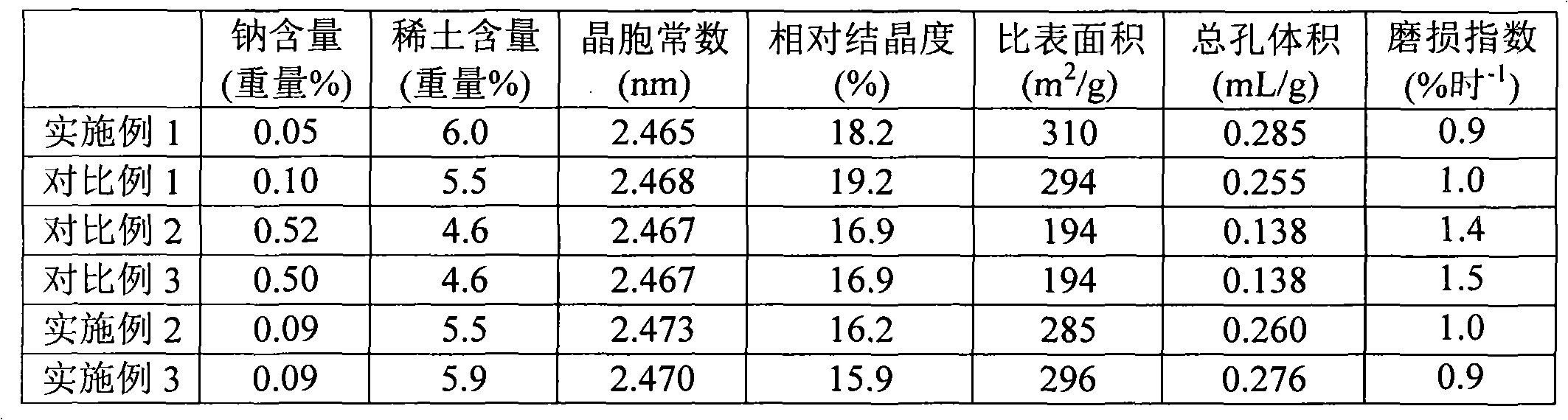

Embodiment 1

[0045] This example is used to illustrate the rare earth-containing Y-type molecular sieve cracking catalyst and its preparation method provided by the present invention.

[0046] (1) Preparation of catalyst precursor

[0047] Mix 3000g kaolin (purchased from Suzhou Kaolin Co., Ltd. on a dry basis), 300g aluminum sol (purchased from Sinopec Catalyst Qilu Branch in terms of alumina) and 4500g decationized water, and beat to obtain slurry M1; Bauxite (calculated as alumina, purchased from Shandong Aluminum Works), 10000g decationized water and 310ml hydrochloric acid (HCl content is 36% by weight) are mixed, beating to obtain slurry M2; M1 and M2 are mixed, stirred evenly, Stand at ℃ for aging for 1 hour, add 1550 g of NaY molecular sieve without ion exchange (on a dry basis, purchased from Sinopec Catalyst Qilu Branch) under stirring, stir evenly, and then carry out spray-drying molding to obtain a catalyst precursor.

[0048] (2) The first ion exchange

[0049] 150 g of the ...

Embodiment 2

[0061] This example is used to illustrate the rare earth-containing Y-type molecular sieve cracking catalyst and its preparation method provided by the present invention.

[0062] (1) Preparation of catalyst precursor

[0063] 3000g kaolin (on a dry basis, purchased from Suzhou Kaolin Co.), 1500g deionized water and 452ml hydrochloric acid (HCl content is 36% by weight) were mixed, beaten, and then added 2000g pseudoboehmite (calculated on alumina, purchased From Shandong Aluminum Works), stirred for 1 hour, left to age at 60-70° C. for 1 hour, added 3550 g of ion-exchanged NaY molecular sieves (on a dry basis, purchased from Sinopec Catalyst Qilu Branch) under stirring, and stirred homogeneous, and then spray-dried to obtain a catalyst precursor.

[0064] (2) The first ion exchange

[0065]150 g of the catalyst precursor prepared in (1) was calcined at 390° C. for 0.5 hours, and then the calcined catalyst precursor was beaten with 1500 mL of decationized water, and 100 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com