Inorganic foam heat insulating material with second-grade closed-pore structure and preparation method thereof

A technology of inorganic foam and thermal insulation materials, which is applied in household appliances, ceramic products, and other household appliances, etc., can solve the problems of different physical and chemical characteristics, complex composition of coal gangue, different requirements for chemical composition and physical and chemical properties of coal gangue, etc. Achieve high compressive strength, simple and convenient preparation method, and improve heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing an inorganic foam insulation material with a secondary closed-cell structure, comprising the following steps:

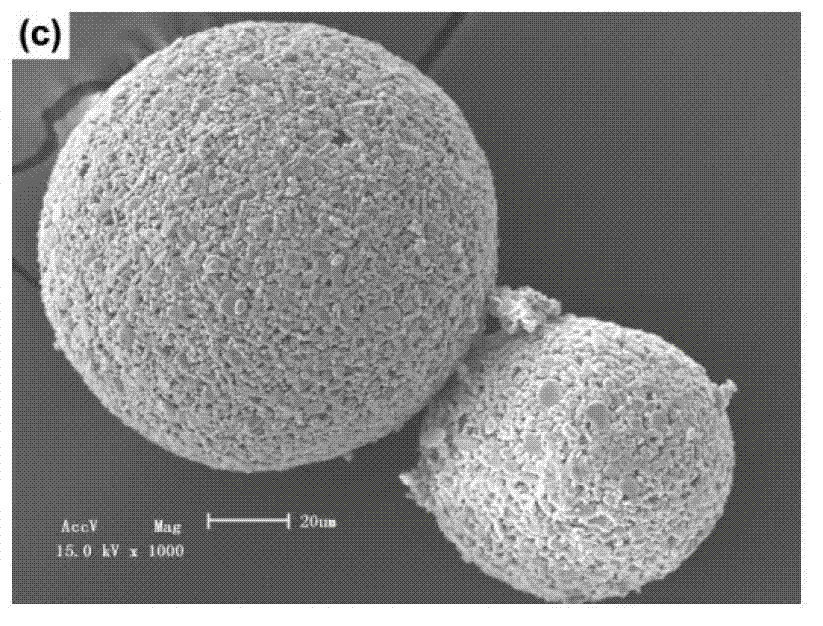

[0042] Step 1: Weigh 70-100 parts by weight of hollow spheres, 35-80 parts by weight of cementitious material, 0-5 parts by weight of fibers, 0-12 parts by weight of reinforcing agent and 0-5 parts by weight of water-repellent agent, and prepare uniformly mixed Powder;

[0043] Step 2: Add 76-154 parts by weight of water to the uniformly mixed powder, the water-material ratio is 0.60-0.76, stir, and prepare the uniformly mixed powder into a uniformly dispersed slurry;

[0044] Step 3: Add 0.1 to 2.5 parts by weight of foaming agent or prefabricated foam to the above slurry, the volume of the foam is 2 to 8 times the volume of the slurry, and fully stir to prepare a stable foam slurry;

[0045] Step 4: Pour the stable foam slurry into the mold to form it, and dry it naturally after curing.

[0046] In step 3, the stirring time is 10-180...

Embodiment 1

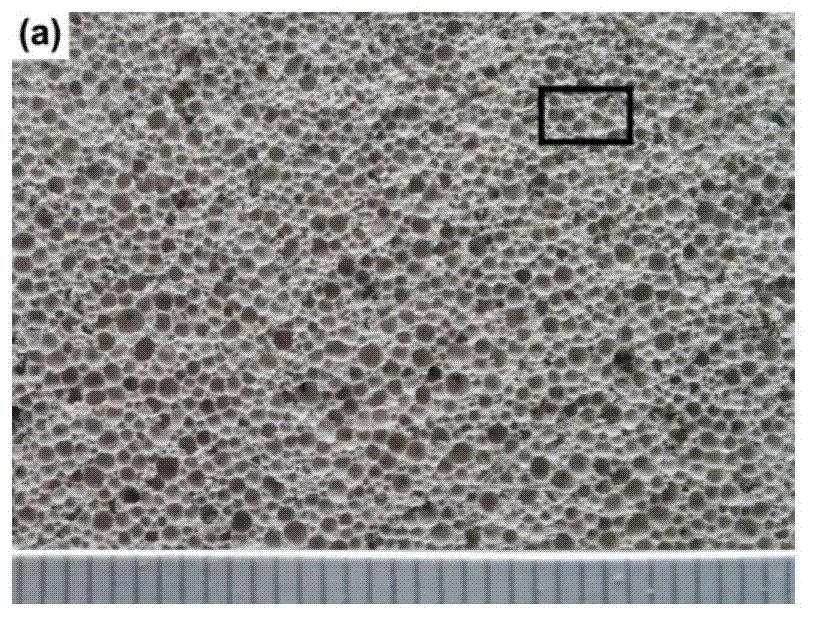

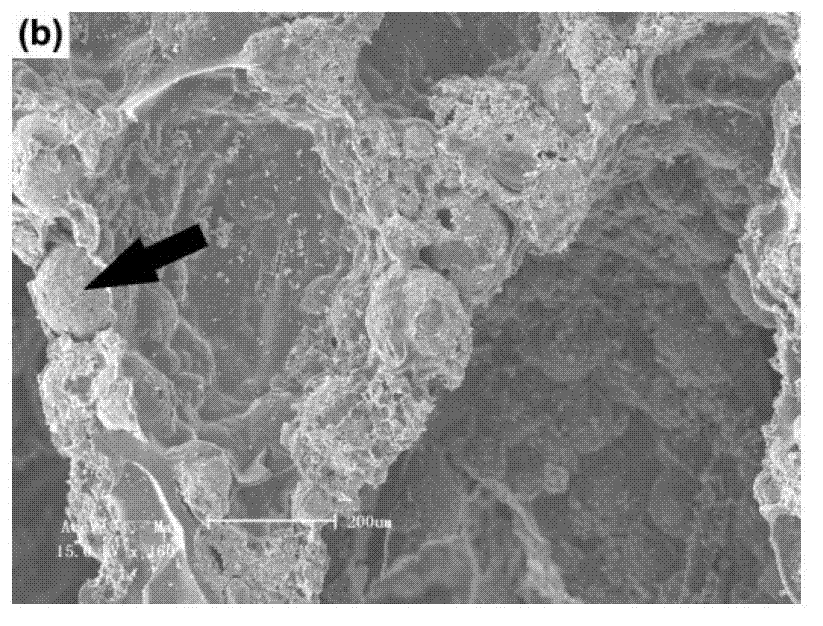

[0048] The mass ratio of hollow sphere, water glass, glass fiber, reinforcing agent, water repellent and water is 70:30:3:5:4:60. Mix the above raw materials evenly and stir for a period of time to obtain a slurry. Preparation of foaming agent aqueous solution: Dilute the animal foaming agent by 1:100 to obtain the foaming agent aqueous solution, then add the foaming agent aqueous solution to the foaming machine, and make foam by the foaming machine. Add the foam to the above slurry, the volume of the added foam is 4 times the volume of the slurry, stir the foam and the slurry evenly, after pouring, curing, and molding, an inorganic hollow ball foam insulation material with a secondary closed-cell structure is obtained .

Embodiment 2

[0050] The mass ratio between hollow spheres, aluminum dihydrogen phosphate, aluminum dihydrogen phosphate curing agent, polypropylene fiber, reinforcing agent, water-repellent agent, and water is 60:40:5:4:3:4:90, and the above raw materials Mix well and stir for a while to get a slurry. Preparation of foaming agent aqueous solution: Dilute the animal foaming agent by 1:100 to obtain the foaming agent aqueous solution, then add the foaming agent aqueous solution to the foaming machine, and make foam by the foaming machine. Add the foam to the above slurry, the volume of the added foam is 5 times the volume of the slurry, stir the foam and the slurry evenly, after pouring, curing, and molding, an inorganic hollow ball foam insulation material with a secondary closed-cell structure is obtained .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com