Re-combustion hot gas generating furnace

A technology of hot gas generation and generator, applied in the direction of combustion method, combustion equipment, fuel supply, etc., which can solve the problems of not meeting environmental protection requirements, unrealizable fluidity, and lack of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

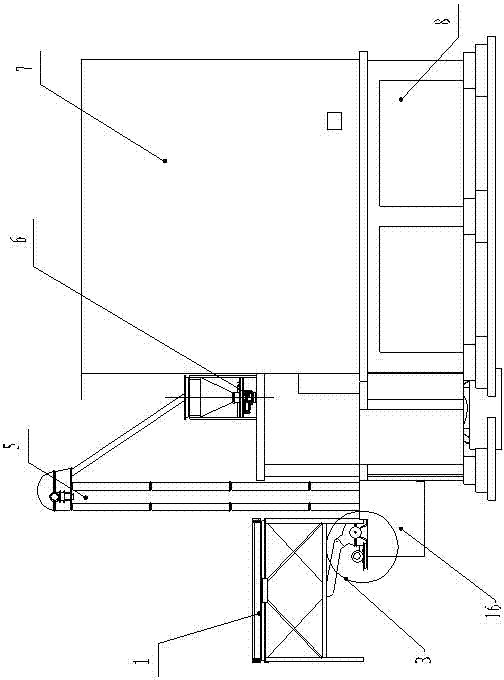

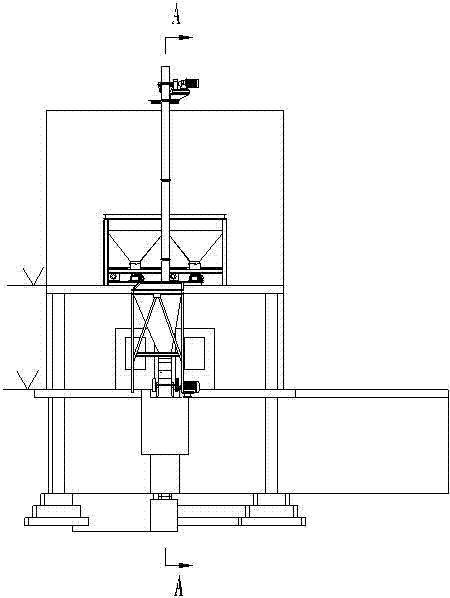

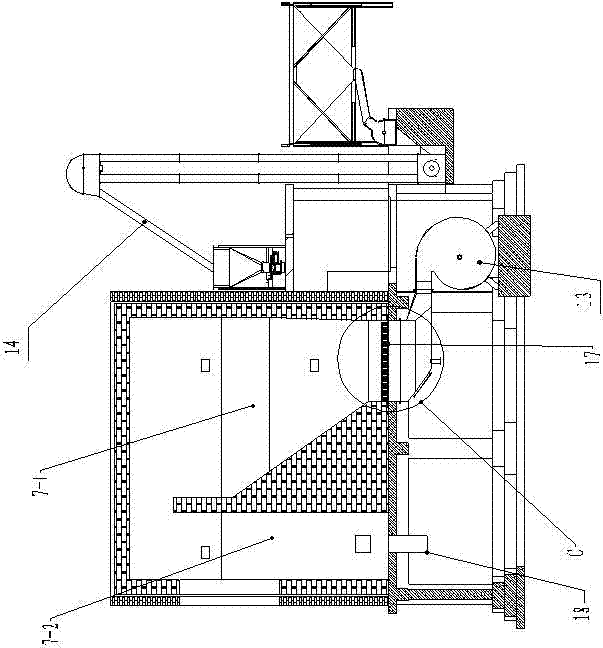

[0025] like figure 1 , 2 , 3, 4, 5, 6, 7, 8, a kind of post-combustion hot gas generator, including generator furnace body 7, also includes raw coal batching bin 1, bucket elevator 5, disc feeder 6, Blower 13, the bottom of the raw coal batching bin 1 is provided with a coal pulverizer 2 connected thereto, the coal pulverizer 2 communicates with the pulverized coal storage bin 16, and the pulverized coal storage bin 16 passes through the hopper Type hoist 5, chute 14 are communicated with disc feeder 6, and this disc feeder 6 is communicated with generator furnace body 7, and described generator furnace body 7 bottoms are provided with air inlet 17, and at air inlet The position 17 is provided with an air distribution plate 10, and the air distribution plate 10 is provided with a wind cap 9, and the air inlet 17 communicates with the blower 13 through the bellows 11.

[0026] The described generator furnace body 7 is fixedly arranged on the generator furnace body foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com