Biodegradable lubricating oil composition having flame retardancy

A lubricating oil composition and a biodegradable technology, applied in the field of biodegradable lubricating oil compositions, can solve problems such as promoting fire, and achieve the effects of excellent flame retardancy and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

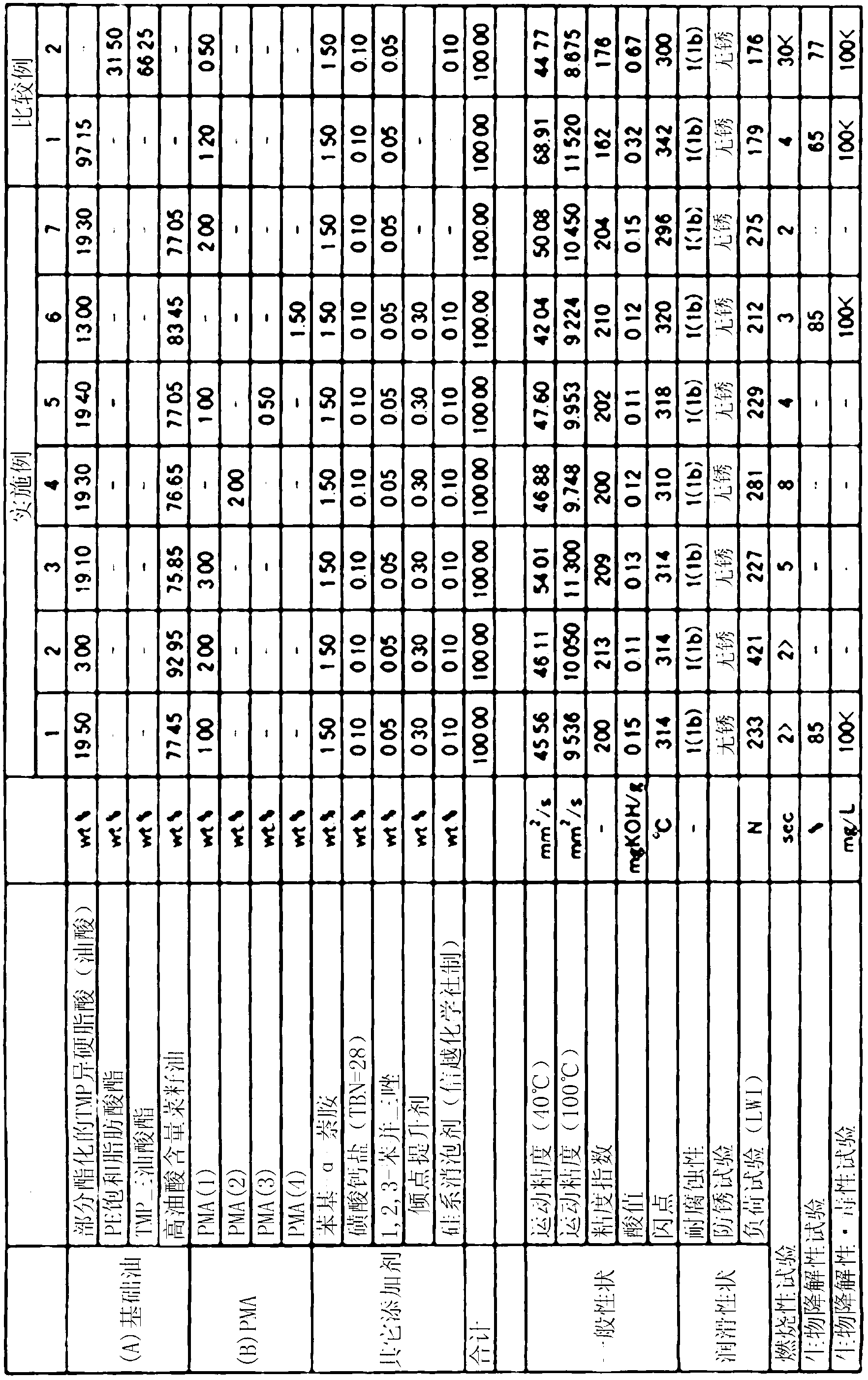

Embodiment 1~7 and comparative example 1、2

[0067] The plant-derived oil and polyol ester were mixed in the amounts shown in Table 1 to prepare a base oil, and then the polymethacrylate and other additives shown in Table 1 were added to the base oil. For each lubricating oil combination obtained The materials, as described below, were evaluated for general properties, lubricating properties, combustion properties, and biodegradability. The results are shown in Table 1. In addition, the details of the used vegetable-derived oil, polyol ester, and polymethacrylate are shown below.

[0068] (oil from vegetable)

[0069] Rapeseed oil with high oleic acid content: 73% by mass of oleic acid, 4% by mass of fatty acids having 16 or less carbon atoms, and 22% by mass of fatty acids having 18 carbon atoms (excluding oleic acid)

[0070] (polyol ester)

[0071] Partially esterified TMP (trimethylolpropane) isostearic acid (oleic acid): 40°C kinematic viscosity of 60.0mm 2 / s, 100℃ kinematic viscosity is 10.0mm 2 / s, the acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com