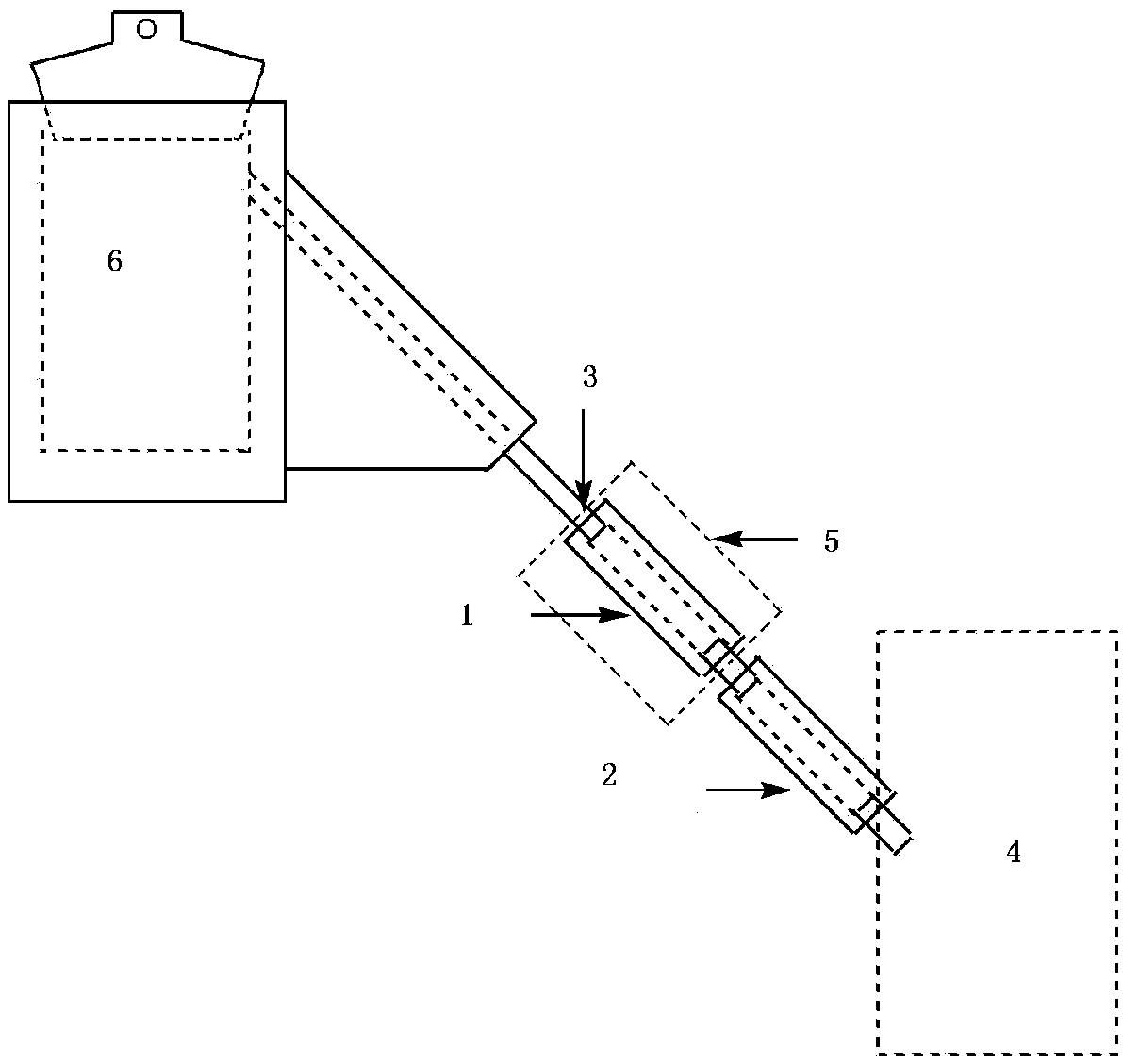

Oil-water separator in oil shale dry distillation analysis and oil-water content determination method

An oil-water separation device and oil shale technology, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of oil shale oil content error, shale oil and water loss, long operation time, etc., to achieve The effects of slow heat transfer, shortened experiment time, and simple collection and separation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Weigh 10.03g of oil shale with a particle size less than 2mm, and put it into an aluminum retort. Connect the oil suction device and the water suction device successively at the air guide pipe of the aluminum retort. The oil absorbing device adopts a glass tube with a diameter of 0.9cm and a length of 9cm, which contains 3g of polypropylene fiber material. The temperature of the oil absorbing device is controlled at 80°C; the water absorbing device adopts a glass tube with an inner diameter of 0.9cm and a length of 7cm, and contains 1g of cross-linked polyacrylic acid Super absorbent resin, keep the air unobstructed. Heat the aluminum retort at a heating rate of 10°C / min, and keep the temperature at 520°C for 20 minutes. Remove the water absorbing device and the oil absorbing device, take out the semi-coke, and weigh the quality of the oil absorbing device, water absorbing device and semi-coke respectively. The mass of the oil absorption device before carbonization was...

Embodiment 2

[0035] Weigh 51.21 grams of oil shale with a particle size of less than 2 mm, and put it into an aluminum retort. Connect the oil suction device and the water suction device successively at the air guide pipe of the aluminum retort. The oil absorbing device adopts a glass tube with an inner diameter of 3.6cm and a length of 9cm, which contains 9g of polypropylene fiber material. The temperature of the oil absorbing device is controlled at 70°C; the water absorbing device adopts a glass tube with an inner diameter of 3.6cm and a length of 7cm, and contains 40g of colorless silica gel. Keep the gas flowing. Heat the aluminum retort at a heating rate of 10°C / min, and keep the temperature at 520°C for 20 minutes. Remove the water suction device and the oil suction device, and take out the semi-coke. The mass of the oil absorption device before carbonization was 49.17 grams and that of the oil absorption device after carbonization was 56.56 grams. The mass of the water absorption...

Embodiment 3

[0037] Weigh 5.01 grams of oil shale with a particle size of less than 2mm, and put it into an aluminum retort. Connect the oil suction device and the water suction device successively at the air guide pipe of the aluminum retort. The oil absorbing device adopts a glass tube with a diameter of 1.1 cm and a length of 9 cm, and contains 0.7 g of modified expanded perlite. The temperature of the oil absorbing device is controlled at 75 ° C; the water absorbing device adopts a glass tube with an inner diameter of 1.1 cm and a length of 7 cm, and contains 4 g of colorless Silicone, keep the gas unobstructed. Heat the aluminum retort at a heating rate of 10°C / min, and keep the temperature at 520°C for 20 minutes. Remove the water suction device and the oil suction device, and take out the semi-coke. The mass of the oil absorption device before carbonization was 5.18 grams, the mass of the oil absorption device after carbonization was 5.34 grams, the mass of the water absorption de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com