Method for manufacturing high-voltage electro-ceramic insulator

A technology of high-voltage electric porcelain and its manufacturing method, which is applied in the field of electric porcelain equipment, can solve the problems of poor resistance to rapid changes in cold and heat, poor antifouling performance, excessive harmful stress expansion coefficient, and loss of strength of insulators, and achieve excellent electrical performance and good insulation shock. Wear strength, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

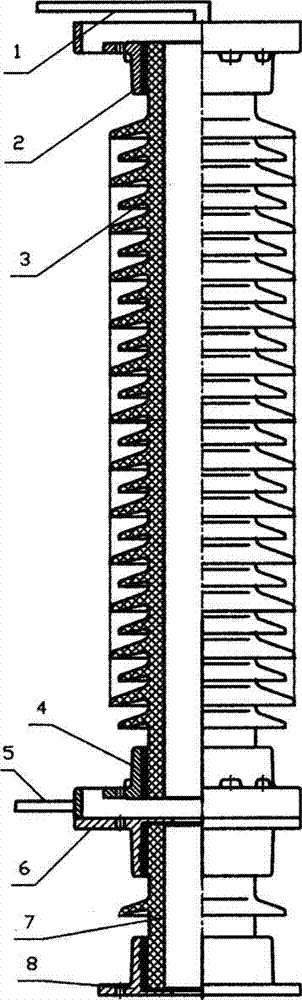

Image

Examples

Embodiment 1

[0039] A method for manufacturing a high-voltage electric porcelain insulator, the specific steps of which are as follows:

[0040] (1) Weight percentage of high voltage electric ceramic material components:

[0041] 30% high alumina powder, 5% black mud, 15% Nanzhang soil, 20% left cloud soil, 15% feldspar, 15% refractory soil;

[0042] (2) Material mixing: Mix the above material components according to the percentage requirements, and send them to the ball mill after mixing;

[0043] (3) Ball milling after mixing: Ball milling after mixing: mix the mixed material with water, material: water = 1:1, and mill in the ball mill for 13-17 hours to make the fineness reach 0.8-1.2 %;

[0044] (4) Screening: TW-1-G type equipment is usually used, and the screen density is generally 120-170 holes. To screen the mud, a hexagonal drum screen and a fixed center vibrating screen are used in series, through which the fineness of the billet can be controlled. And keep the mud uniform, an...

Embodiment 2

[0071] A method for manufacturing a high-voltage electric porcelain insulator, the specific steps of which are as follows:

[0072] (1) Weight percentage of high voltage electric ceramic material components:

[0073] High alumina powder 45%, black mud 7%, Nanzhang soil 17%, left cloud soil 14%, feldspar 6%, refractory soil 11%;

[0074] (2) Material mixing: Mix the above material components according to the percentage requirements, and send them to the ball mill after mixing;

[0075] (3) Ball milling after mixing: Ball milling after mixing: mix the mixed material with water, material: water = 1:1, and mill in the ball mill for 13-17 hours to make the fineness reach 0.8-1.2 %;

[0076] (4) Screening: TW-1-G type equipment is usually used, and the screen density is generally 120-170 holes. To screen the mud, a hexagonal drum screen and a fixed center vibrating screen are used in series, through which the fineness of the billet can be controlled. And keep the mud uniform, and...

Embodiment 3

[0103] A method for manufacturing a high-voltage electric porcelain insulator, the specific steps of which are as follows:

[0104] (1) Weight percentage of high voltage electric ceramic material components:

[0105] High alumina powder 55%, black mud 2%, Nanzhang soil 8%, left cloud soil 15%, feldspar 10%, refractory soil 10%;

[0106] (2) Material mixing: Mix the above material components according to the percentage requirements, and send them to the ball mill after mixing;

[0107] (3) Ball milling after mixing: Ball milling after mixing: mix the mixed material with water, material: water = 1:1, and mill in the ball mill for 13-17 hours to make the fineness reach 0.8-1.2 %;

[0108] (4) Screening: TW-1-G type equipment is usually used, and the screen density is generally 120-170 holes. To screen the mud, a hexagonal drum screen and a fixed center vibrating screen are used in series, through which the fineness of the billet can be controlled. And keep the mud uniform, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com