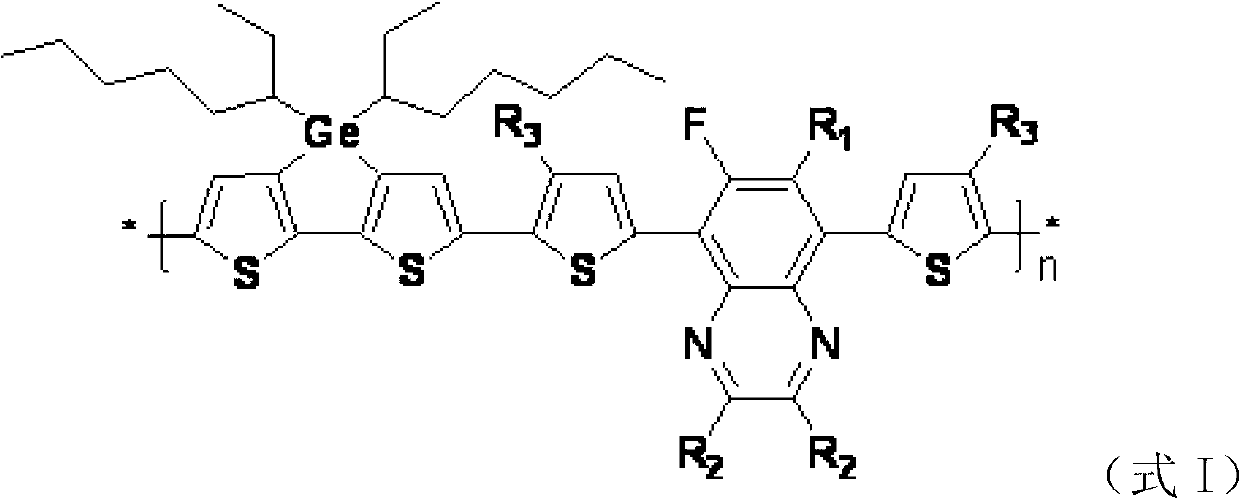

Dithiophene ring-fused germanium pentadiene-fluoroquinoxaline conjugated polymer

A conjugated polymer, double thieno technology, applied in the field of functional polymer materials, to achieve the effect of increasing the open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

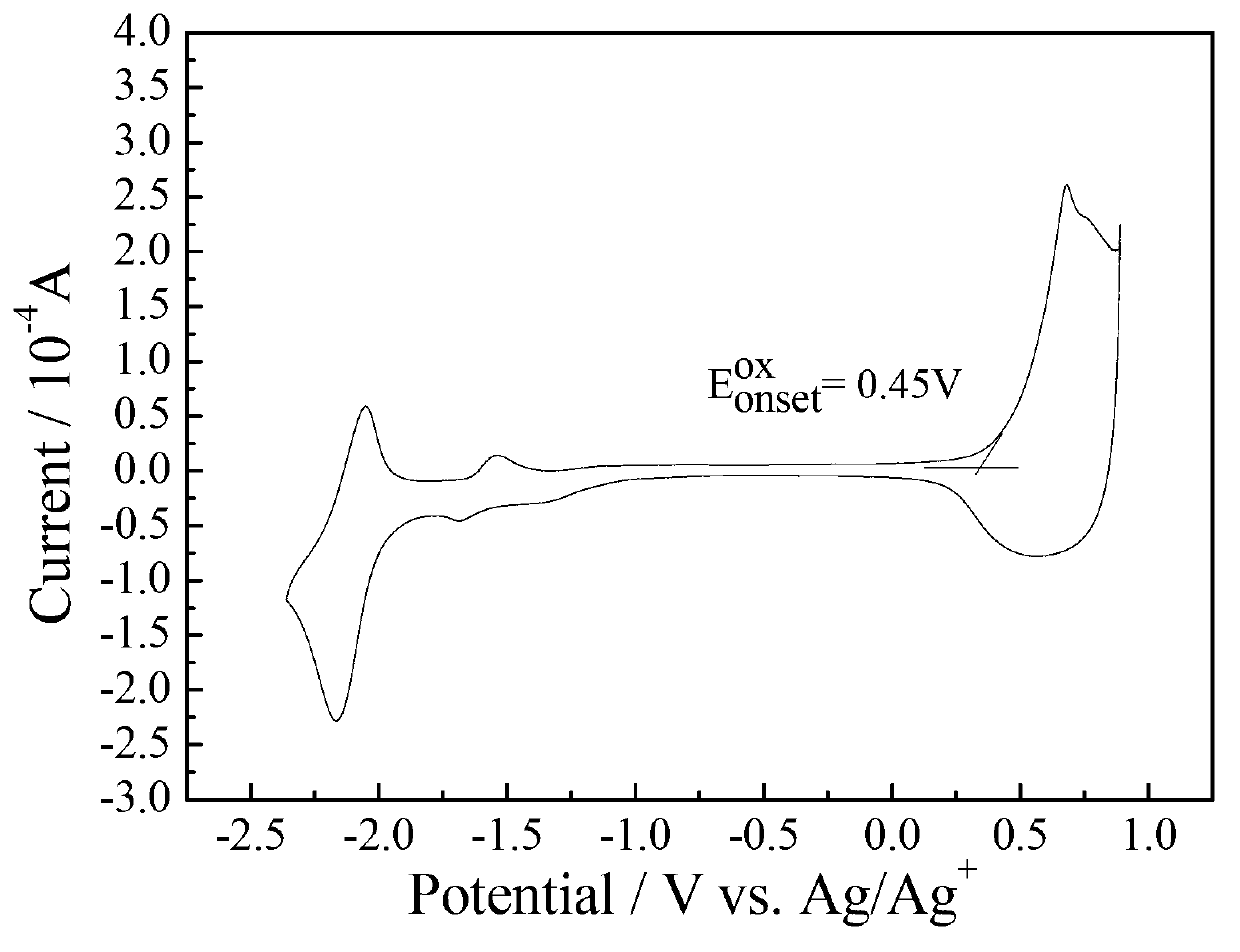

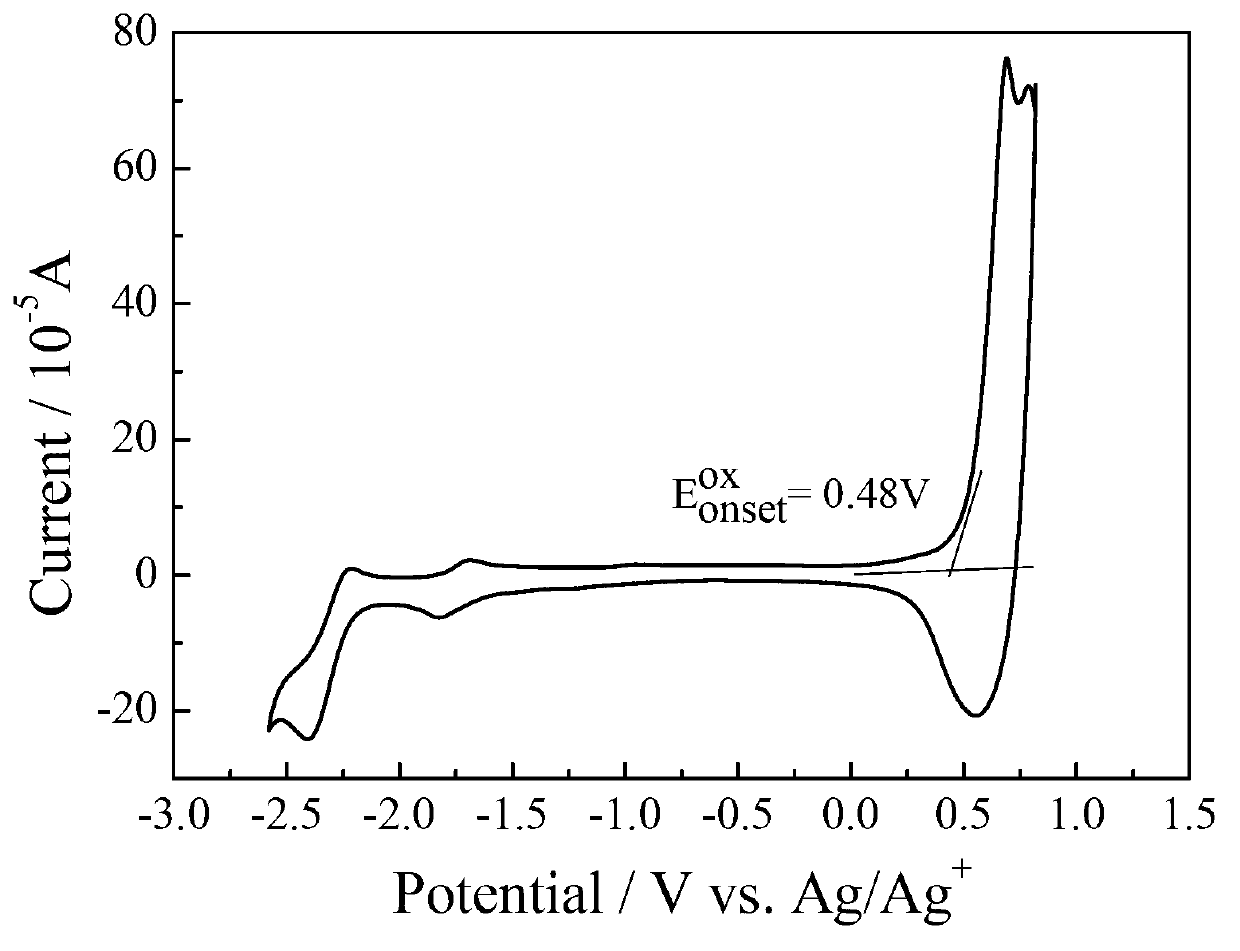

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of 6-fluoro-5,8-bis(5-bromo-4-hexylthiophene)-2,3-bis(3-octyloxyphenyl)quinoxaline:

[0037] (1) The preparation of 4-fluoro-3,6-dibromo-1,2-phenylenediamine (compound 1) is carried out according to the following reaction equation:

[0038]

[0039] 5-Fluoro-4,7-dibromo-2,1,3-benzothiadiazole (5 g, 0.016 mol) was dissolved in 150 ml of absolute ethanol, and NaBH was added in batches at 0 °C 4 (11.1g, 0.29mol), and then reacted at room temperature for 20h. After the reaction, concentrate to remove ethanol, add 160ml of water, extract with ethyl acetate, wash the organic phase with brine, and finally anhydrous MgSO 4 dry. The crude product obtained after concentration to remove the organic solvent was purified by a silica gel column, and the eluent was n-hexane / ethyl acetate (25:1, v / v) to obtain 4-fluoro-3,6-dibromo-1,2- 3.5 g of phenylenediamine, yield 78%.

[0040] (2) Preparation of 1,2-bis(3-octyloxyphenyl)ethanedione (compound 2)

[0041] Follow ...

Embodiment 2

[0056] Synthesis of 6-fluoro-5,8-bis(5-bromo-4-hexylthiophene)-2,3-bis(4-octyloxyphenyl)quinoxaline (compound 9):

[0057] Follow the reaction equation shown below:

[0058]

[0059] The synthesis method is the same as that of compound 5, except that 1,2-bis(3-octyloxyphenyl)ethanedione is replaced by 1,2-bis(4-octyloxyphenyl)ethanedione.

Embodiment 3

[0061] Synthesis of 6,7-difluoro-5,8-bis(5-bromo-4-hexylthiophene)-2,3-bis(3-octyloxyphenyl)quinoxaline (compound 14):

[0062] (1) Preparation of 4,5-difluoro-3,6-dibromo-1,2-phenylenediamine (compound 11)

[0063] Follow the reaction equation shown below:

[0064]

[0065] Compound 10 (10g, 0.031mol) was dissolved in 300ml absolute ethanol, and NaBH was added in batches at 0°C 4 (22.2g, 0.59mol), then reacted at room temperature for 5h. After the reaction, concentrate to remove ethanol, add 200ml of water, extract with ethyl acetate, wash the organic phase with saturated brine, and finally anhydrous MgSO 4 dry. The crude product obtained by concentration was purified by silica gel column, and the eluent was n-hexane / ethyl acetate (20:1, v / v) to obtain 4,5-difluoro-3,6-dibromo-1,2-benzene Diamine 6.1g, yield 65%.

[0066] (2) Preparation of 6,7-difluoro-2,3-bis(3-octyloxyphenyl)quinoxaline (compound 12)

[0067] Follow the reaction equation shown below:

[0068] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com