Disperse dye monomeric compound and disperse dye

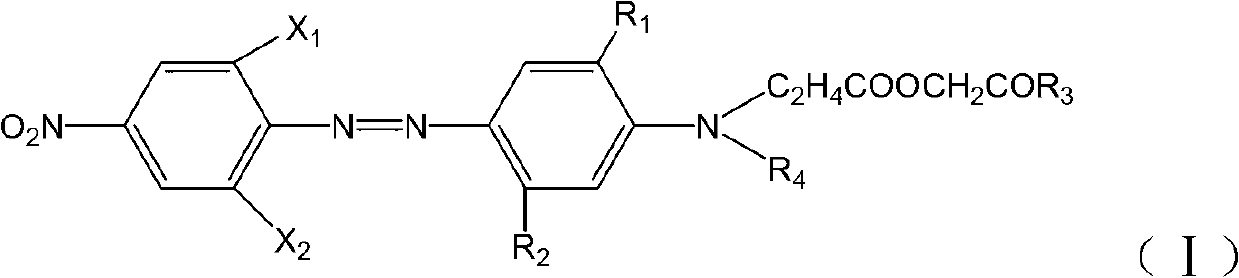

A technology of disperse dyes and dye monomers, applied in azo dyes, organic dyes, monoazo dyes, etc., to achieve the effect of high color yield, strong dye depth and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

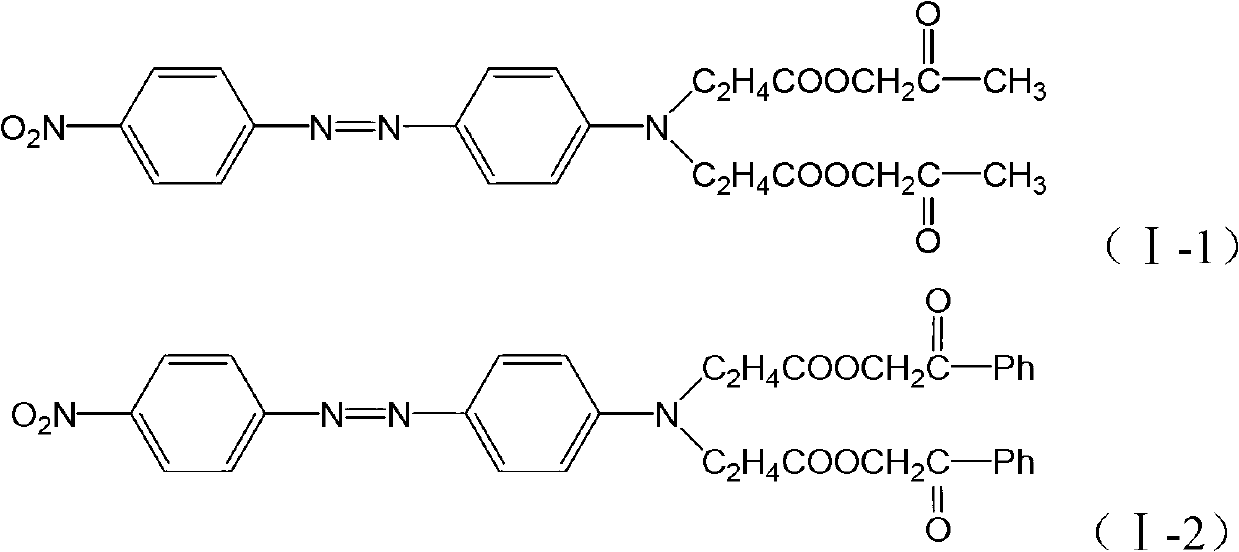

Embodiment 1

[0031] Preparation of the coupling component represented by formula (Ⅲ-1) (N,N-dimethylcarbonylmethoxycarbonylethylaniline):

[0032] Put 18.6g of aniline, 72g of acrylic acid and 100g of water into a 500ml container, raise the temperature to 90°C, keep it warm for 10h, add 100g of methanol while cooling down, keep stirring at 0~5°C for 12h; then crystallize and filter, wash with 50g of methanol, and dry. A dicarboxylic acid product is obtained. Put 68.5g of bromoacetone, 11.6g of soda ash and 23.7g (100%) of the dicarboxylic acid product prepared above into a 500ml container, and raise the temperature to 80°C; then put in 5g of potassium iodide, and keep it warm for 12 hours; then cool down to 40°C, Add 100g of water, crystallize and filter.

[0033]

[0034]

[0035] Diazotization reaction: Put 25g of water into a 500ml container, cool down and add 87g of concentrated sulfuric acid, and continue to cool down to 10°C; add 13.8g of p-nitroaniline, and stir at 20~30°C fo...

Embodiment 2

[0039] Preparation of the coupling component represented by formula (Ⅲ-2) (N,N-diphenylcarbonylmethoxycarbonylethylaniline):

[0040] Put 18.6g of aniline, 72g of acrylic acid and 100g of water into a 500ml container, raise the temperature to 90°C, keep it warm for 10h, add 100g of methanol while cooling down, keep stirring at 0~5°C for 12h; then crystallize and filter, wash with 50g of methanol, and dry. A dicarboxylic acid product is obtained. Put 100.4g of 2-bromoacetophenone, 11.6g of soda ash and 23.7g (percentage) of the above-prepared dicarboxylic acid product into a 500ml container, raise the temperature to 80°C, add 5g of potassium iodide, and keep the temperature for 12h; then cool down To 40°C, add 200g of water, crystallize and filter.

[0041]

[0042]Diazotization reaction: Put 25g of water into a 500ml container, cool down and add 87g of concentrated sulfuric acid, and continue to cool down to 10°C; add 13.8g of p-nitroaniline, and stir at 20~30°C for 4 hour...

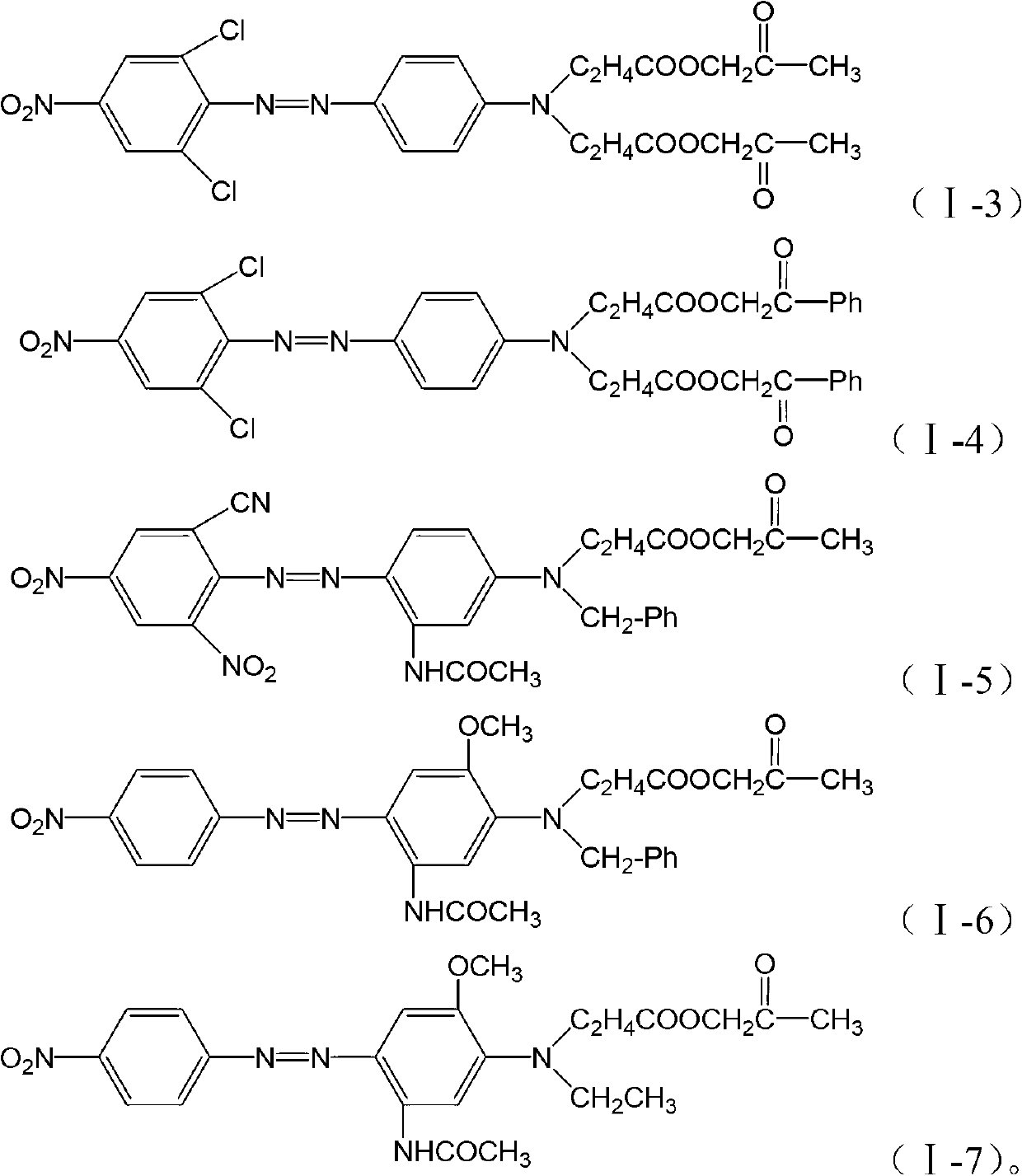

Embodiment 3

[0046] Diazotization reaction: Add 80g of concentrated sulfuric acid and 35g of 40% nitrosyl sulfuric acid to a 500ml container, cool down to 0~5°C, and add 20.7g of 2,6-dichloro-p-nitroaniline within 3~4h, add After the heat preservation for 3 hours, the diazo solution (for standby) was prepared.

[0047] Coupling reaction: put 1000g of water, 20g of concentrated sulfuric acid and 34.9g (percentage) of the coupling component of formula (Ⅲ-1) into a 2L container, beat for half an hour; distill the diazo solution prepared above within 1-2h Add it dropwise into the beating liquid of the coupling component, control the temperature at 0~5°C and react for 5~6h; after the end point is reached (detect the reaction with the percolation ring test), raise the temperature of the material to 75°C, and keep it warm for 3h; finally filter and wash until Neutral, the dye filter cake shown in formula (Ⅰ-3) can be prepared, λ max [DMF]=433nm, the dyed fabric is brown tone.

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com