Device for quickly detecting pesticide residues in fruits and vegetables, and application thereof

A technology for pesticide residues, fruits and vegetables, which is applied in the field of pesticide residue detection devices, can solve the problems of separation, misjudgment of conclusions, and interference with the accuracy of photometric detection results, so as to achieve accurate detection results and eliminate interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

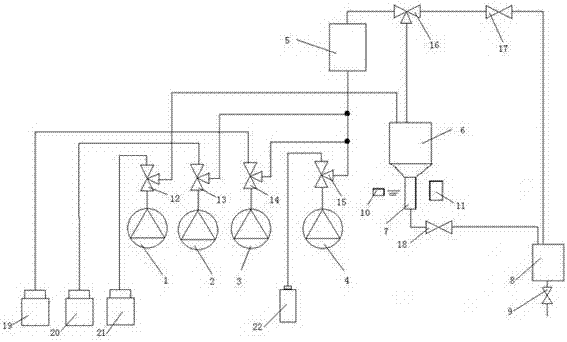

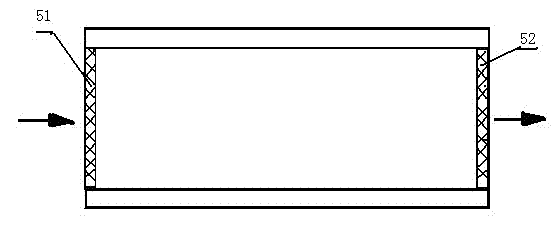

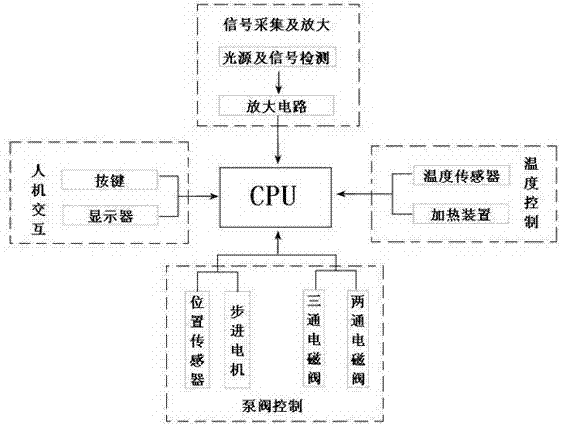

[0061] A rapid detection device for pesticide residues in fruits and vegetables, the schematic diagram of its structure and principle is shown in figure 1 As shown, it includes chromogenic pool 6, waste liquid pool 8, sample liquid supply device 22, chromogenic liquid supply device 21, buffer solution supply device 20, substrate supply device 19, sample liquid pump 4, substrate pump 3, display A color liquid pump 1, a buffer pump 2, a valve system and an electronic measurement and control system, and also includes a reactor 5 for carrying enzymes used in the detection of pesticide residues in immobilized fruits and vegetables;

[0062] The sample liquid pump 4, the substrate pump 3, the chromogenic liquid pump 1, and the buffer pump 2 are all selected plunger pumps, and are respectively provided with corresponding position sensors, and each of the described plunger pumps is started by its Corresponding stepping motor to control;

[0063] The valve system includes three-way va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com