Polyurethane rigid foam used for thermal insulation technique of wall

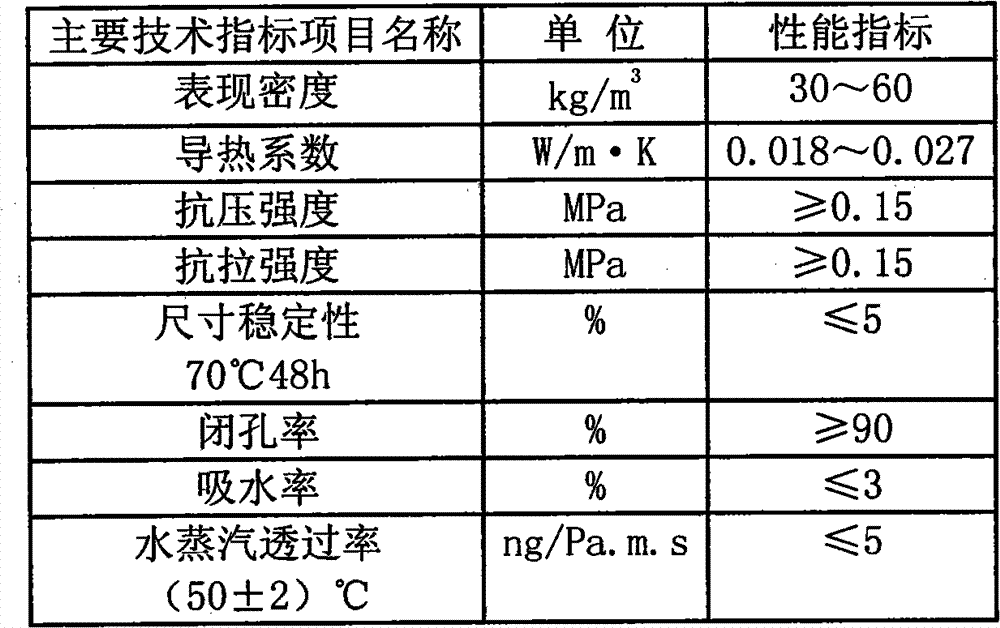

A technology of rigid polyurethane foam and polyurethane spraying, which is applied in thermal insulation, building components, construction, etc., can solve problems such as thermal and cold bridges, and achieve the effects of low thermal conductivity, increased service life, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

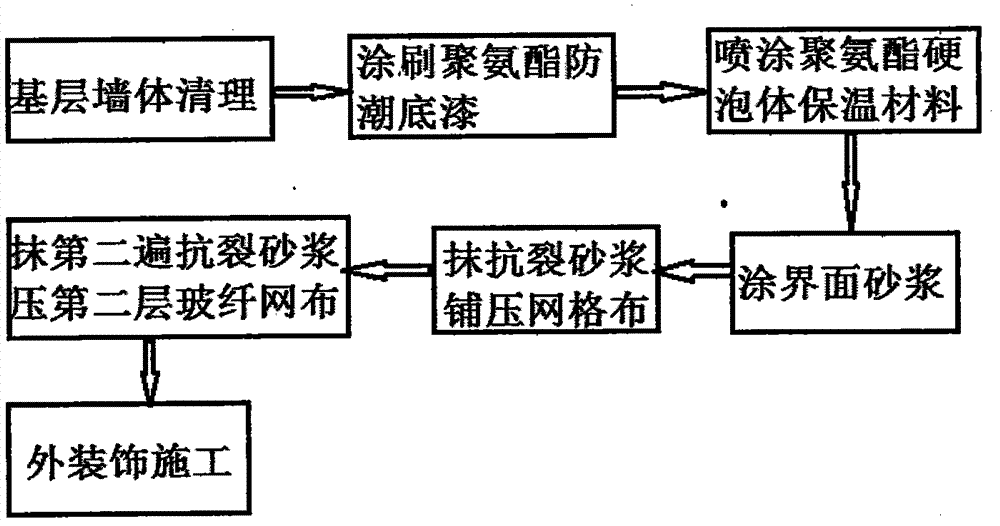

[0018] The technological process of polyurethane rigid foam used for wall insulation is as follows: base wall cleaning, painting polyurethane moisture-proof primer, spraying polyurethane rigid foam insulation material, coating interface mortar, applying anti-cracking mortar, laying grid cloth, and wiping the second layer. The anti-cracking mortar is applied twice, the second layer of glass fiber mesh cloth is pressed in, and finally the exterior decoration construction is carried out.

[0019] In this embodiment, in the steps of applying anti-cracking mortar and laying grid cloth, what is laid and pressed is alkali-resistant grid cloth.

[0020] In this embodiment, glass fiber is added to the rigid polyurethane foam as a toughening agent. Polyester fiber can also be added as a toughening agent. After the toughening agent is added, the single micropores can be cross-linked with each other to form a network structure, which solves the problem of powder dropping and further enha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com