Engine thermal management system

A thermal management system and engine technology, applied in engine components, machines/engines, engine cooling, etc., can solve problems affecting engine work efficiency, backward cooling methods, low engine temperature, etc., to reduce pollutant emissions and maximize efficiency. The best effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

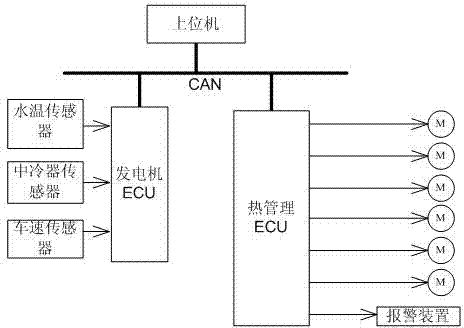

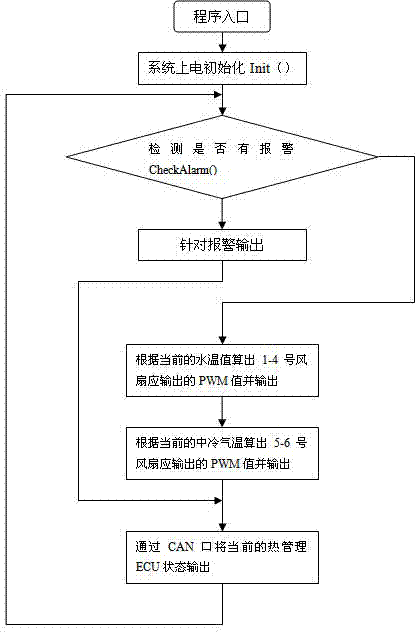

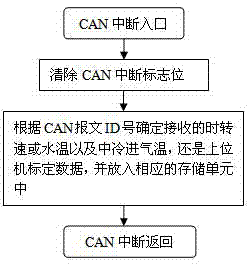

[0016] like figure 1 , for vehicles with CAN network, the engine thermal management system is built on the basis of the original vehicle electrical control system. The original vehicle electrical control system includes a CAN bus. The CAN bus is connected with a host computer and an engine ECU, and the engine ECU is connected with a vehicle speed sensor (the above belongs to the prior art and will not be described in detail). On this basis, install the engine water temperature sensor and the intercooler temperature sensor at the corresponding positions of the engine and the intercooler in the car. These two sensors are also connected to the engine ECU, and the engine ECU performs A / D conversion on the output signals of the two sensors. , the converted data is sent to the CAN bus, and is taken by the thermal management ECU connected to the bus. After processing and analysis, it drives a corresponding group of cooling fans. In this embodiment, the group of cooling fans includes ...

Embodiment 2

[0021] like Figure 5 As shown, this implementation is suitable for vehicles without CAN network. At this time, the engine water temperature sensor and the intercooler temperature sensor are connected to the thermal management ECU, so the thermal management ECU should have a corresponding AD interface, that is, an analog signal acquisition port. Image 6 It is a process of AD acquisition by means of timing interruption. In Embodiment 1, these AD interfaces can also be reserved for the thermal management ECU for backup.

[0022] In this embodiment, the thermal management ECU directly controls the fan according to the collected information, and the specific process will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com