TN (tunnel nitrate)-SONOS (silicon oxide nitrate oxide silicon) memory with composite nitrogen-based dielectric tunneling layer

A TN-SONOS, composite medium technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve the problem of not being able to simultaneously meet the data writing and erasing speed and data static retention characteristics, and the silicon nitride storage layer is resistant to erasing and writing. The ability and data retention ability are reduced, and it is difficult to meet the requirements of the speed of data writing and erasing, so as to improve the data retention characteristics, reduce traps and interface states, and improve the erasing rate and operation window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a specific manufacturing method of the memory of the present invention.

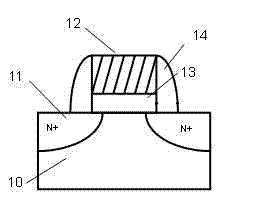

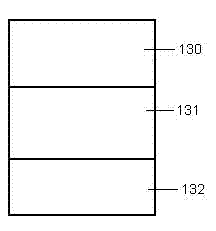

[0029]Firstly, a semiconductor substrate is provided, and then a layer of SiON is formed by dry oxygen oxidation on the substrate in an atmosphere containing nitrogen. (x) , where the value of x is 1.25, and the layer thickness is 13?. Then use LPCVD on SiON (x) A layer of Si is formed on top 3 N 4 , a thickness of 20?. Then use LPCVD technique on Si 3 N 4 SiON (y) , where the value of y is 1.65 and the thickness is 35?. After the tunneling layer is formed, LPCVD technology is used to form 60? Si 3 N 4 Charge trapping layer and 60? SiO2 blocking layer. Then a polysilicon gate is formed on it by LPCVD, and side wall structures are formed on both sides of the gate. Finally, source and drain regions are formed by self-aligned ion implantation.

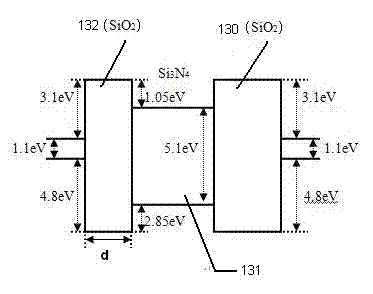

[0030] image 3 Shown is a schematic diagram of the energy bands of the dielectric stack between the gate and channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com