Synthetic method for controllable lithium ion battery cathode material lithium iron phosphate

A lithium-ion battery, lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as general electrochemical capacity, processing performance, and general consistency performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

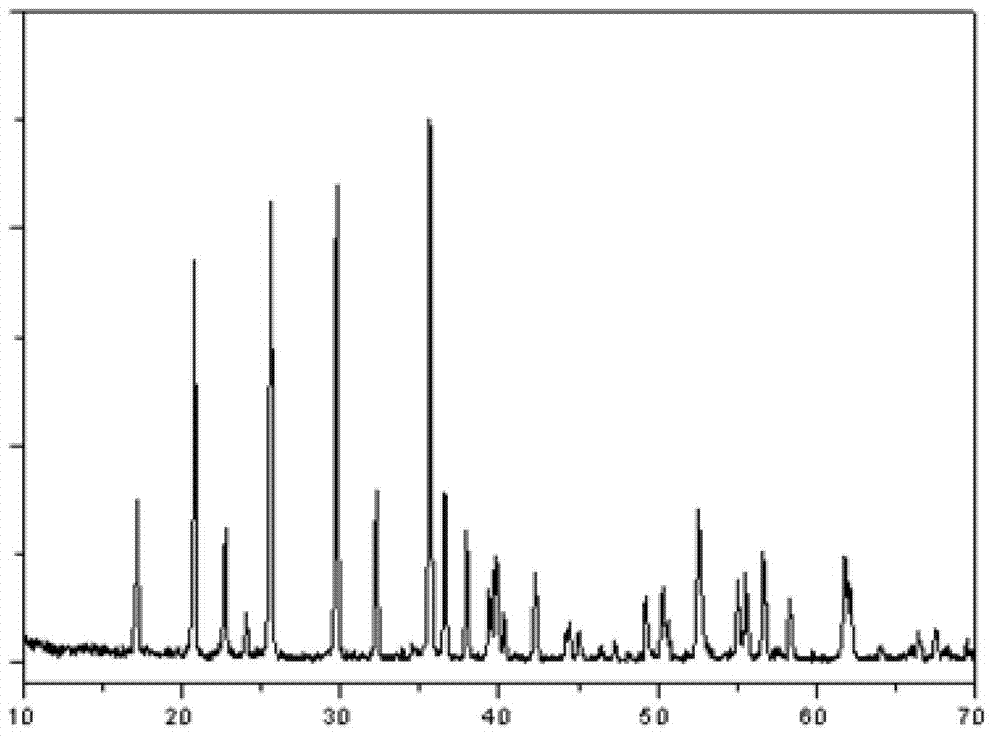

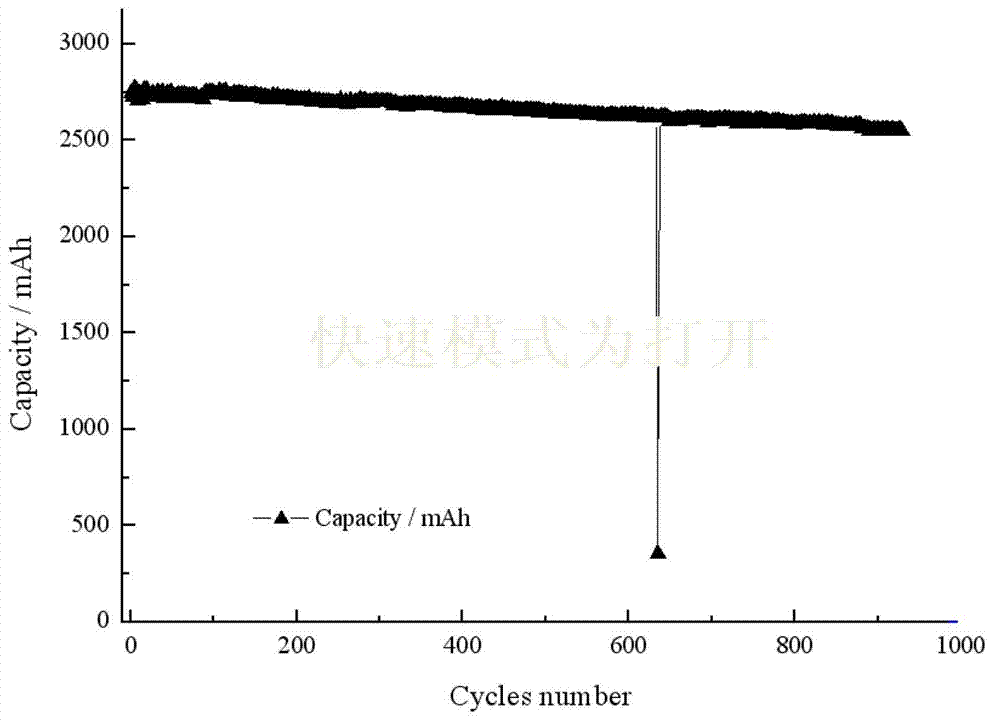

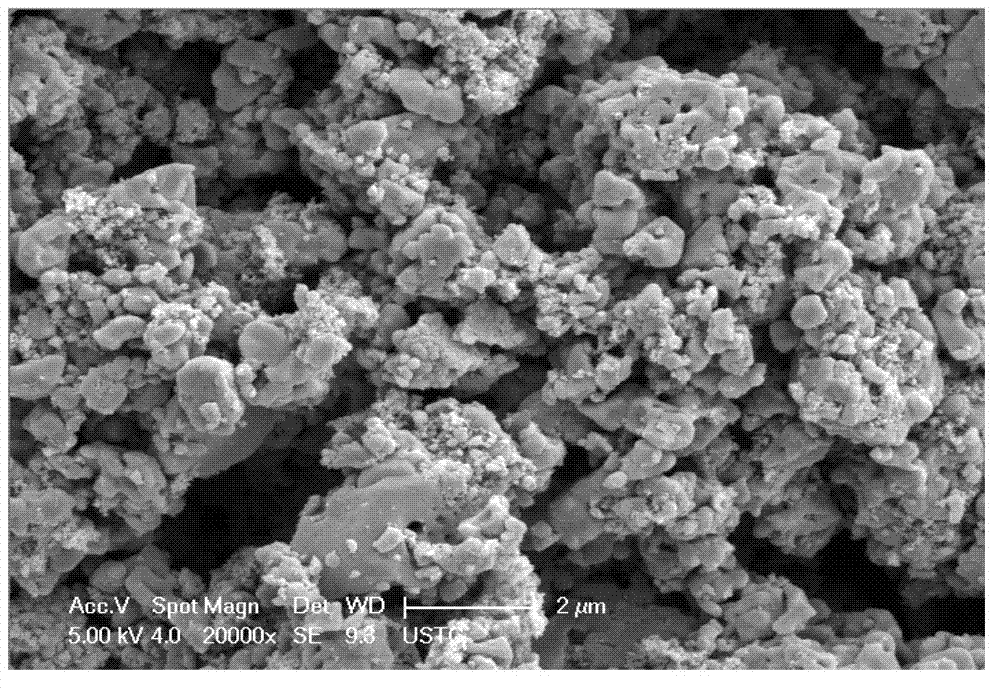

[0023] Weigh 2000g of micron-sized iron oxide, 2740g of battery-grade lithium dihydrogen phosphate, 196g of magnesium acetate and 104g of sucrose, and add the raw materials to a stirring mill added with 5000mL of deionized water, control the stirring speed at 500 rpm, stir and grind 4h. Add 2000 mL of deionized water, add 216 g of acetylene ink into the stirring mill, control the stirring speed at 500 rpm, and stir and grind for 1 hour. The ground slurry was spray-dried to obtain a dry precursor powder, and the dry precursor powder was calcined at 650° C. for 4 hours under the protection of nitrogen to obtain a calcined material. Weigh 2000g of calcined material and 80g of sucrose, add deionized water according to 50% solid content, grind in a stirring mill for 1h, spray dry and collect the slurry to obtain secondary dry material. The above-mentioned secondary dried powder was kept at 750° C. under nitrogen protection for 4 hours to obtain a carbon-coated lithium iron phospha...

Embodiment 2

[0025] Weigh 2000g of micron-sized iron oxide, 2740g of battery-grade lithium dihydrogen phosphate, 156.8g of magnesium acetate and 72.8g of sucrose, and add the raw materials to a stirring mill with 5000mL of deionized water, and control the stirring speed at 500 rpm. Stir and grind for 2h. Add 2000 mL of deionized water, add 296.6 g of acetylene ink into the stirring mill, control the stirring speed at 500 rpm, and stir and grind for 1 hour. The ground slurry was spray-dried to obtain a dry precursor powder, and the dry precursor powder was calcined at 650° C. for 4 hours under the protection of nitrogen to obtain a calcined material. Weigh 2000g of calcined material and 80g of sucrose, add deionized water according to 50% solid content, grind in a stirring mill for 1h, spray dry and collect the slurry to obtain secondary dry material. The above-mentioned secondary dried powder was kept at 750° C. under nitrogen protection for 4 hours to obtain a carbon-coated lithium iron ...

Embodiment 3

[0027] Weigh 2000g of micron-sized iron oxide, 2740g of battery-grade lithium dihydrogen phosphate, 156.8g of magnesium acetate and 182g of sucrose, and add the raw materials to a stirring mill added with 5000mL of deionized water, control the stirring speed at 500 rpm, and stir Grinding for 3h. Add 2000 mL of deionized water, add 273 g of acetylene ink into the stirring mill, control the stirring speed at 500 rpm, and stir and grind for 1 hour. The ground slurry was spray-dried to obtain a dry precursor powder, and the dry precursor powder was calcined at 650° C. for 4 hours under the protection of nitrogen to obtain a calcined material. Weigh 2000g calcined material, 80g sucrose and 60g polyvinyl alcohol, add deionized water according to 50% solid content, grind in a stirring mill for 2h, spray dry the slurry and collect it to obtain secondary dry material. The above-mentioned secondary dried powder was kept at 750° C. under nitrogen protection for 4 hours to obtain a carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com