Preparation method of multi-stage pore channel beta molecular screen

A technology of molecular sieves and channels, which is applied in the field of preparation of multi-stage channel molecular sieves, can solve the problems of discontinuous intercrystalline pores and the decrease of micropore volume of Beta molecular sieves, and achieve the goal of avoiding the loss of molecular sieve quality, reducing synthesis costs, and simplifying synthesis steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First mix 4g of fumed silica, 1.48g of aluminum sulfate and 11.21g of an aqueous solution with a mass fraction of 35% tetraethylammonium hydroxide, and then add 0.132g of sodium hydroxide to obtain the original solution of aluminosilicate. than SiO 2 :Al 2 o 3 :TEA + :OH - =1:0.033:0.4:0.45, stirred at room temperature for 1 hour, then evaporated to dryness at 70°C to obtain "pseudo-solid phase" aluminosilicate, and measured the water content H 2 O and SiO 2 The molar ratio was 2.1. Take 5g of the obtained "pseudo-solid phase" aluminosilicate, and transfer it to a closed static reaction kettle, and crystallize at a crystallization temperature of 140°C for 60h. After the crystallization is completed, the synthesized sample is The rate of 2°C / min was raised from room temperature to 550°C for 4 h at constant temperature to obtain the final sample with a yield of 98%.

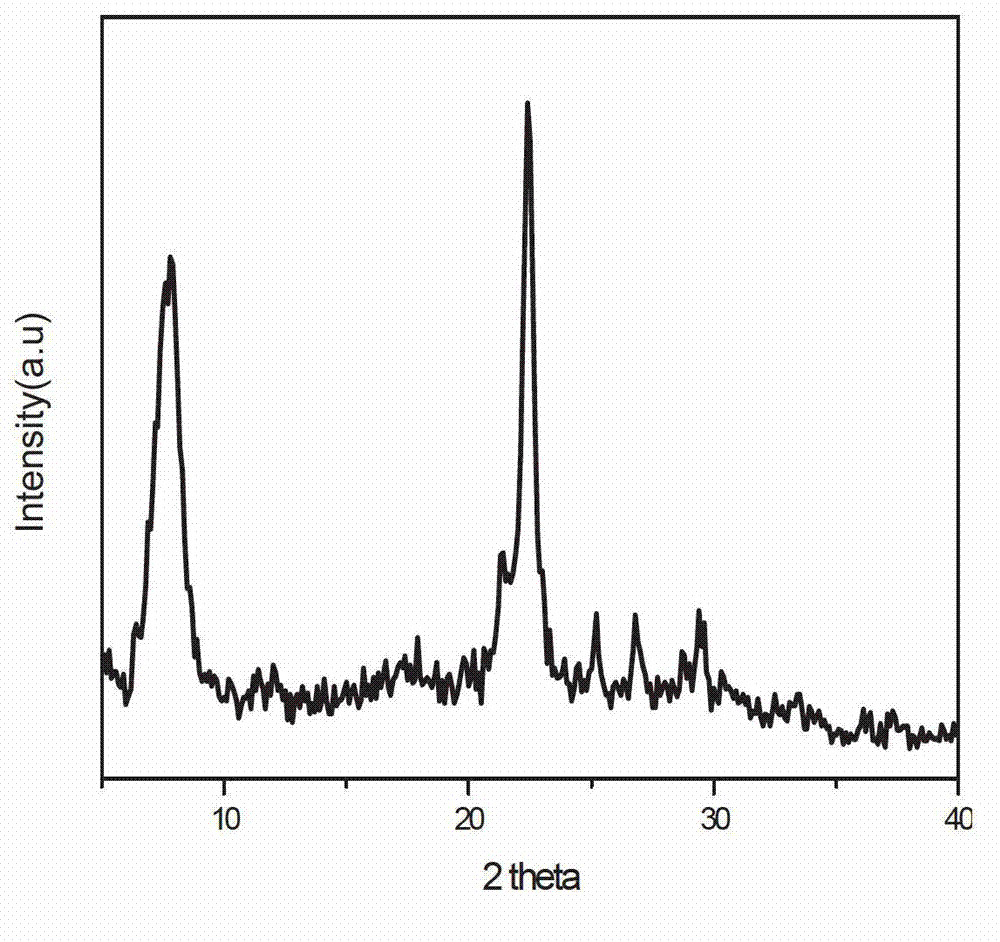

[0031] X-ray diffraction showed that the sample was Beta molecular sieve (attached figure 1 ), an...

Embodiment 2

[0033]First mix 4g of fumed silica, 0.74g of aluminum sulfate and 11.21g of an aqueous solution with a mass fraction of 35% tetraethylammonium hydroxide, and then add 0.132g of sodium hydroxide to obtain the original solution of aluminosilicate. than SiO 2 :Al 2 o 3 :TEA + :OH - =1:0.0167:0.4:0.45, stirred at room temperature for 6 hours, and then evaporated to dryness at 70°C to obtain a "pseudo-solid phase" aluminosilicate, and the water content H 2 O and SiO 2 The molar ratio is 2.1. Take 5g of the obtained "pseudo-solid phase" aluminosilicate, and transfer it to a closed static reaction kettle, and crystallize at a crystallization temperature of 140°C for 60h. After the crystallization is completed, the synthesized sample is The rate of 2°C / min was raised from room temperature to 550°C for 4 h at constant temperature to obtain the final sample with a yield of 98%.

[0034] X-ray diffraction shows that the obtained sample is a Beta molecular sieve, and the specific s...

Embodiment 3

[0036] First mix 33.33g of 30% silicon dioxide, 3.70g of aluminum sulfate and 28.02g of 35% tetraethylammonium hydroxide in water, mix well and then add 0.33g of sodium hydroxide to obtain the original aluminosilicate solution, the molar ratio of raw materials is SiO 2 :Al 2 o 3 :TEA + :OH - =1:0.033:0.4:0.45, stirred at room temperature for 1 hour, then evaporated to dryness at 70°C to obtain "pseudo-solid phase" aluminosilicate, and measured the water content H 2 O and SiO 2 The molar ratio was 3.0. Take 5g of the obtained "pseudo-solid phase" aluminosilicate, and transfer it to a closed static reaction kettle, and crystallize at a crystallization temperature of 140°C for 60h. After the crystallization is completed, the synthesized sample is placed in a muffle furnace Calcined at a constant temperature from room temperature to 550 °C for 4 h at a rate of 2 °C / min, the yield was 99%.

[0037] X-ray diffraction shows that the obtained sample is a Beta molecular sieve, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com