Method for extracting potassium from sea water by using continuous ion exchange method

A continuous ion and ion exchange column technology, applied in the field of seawater treatment by ion exchange, can solve the problems of low recovery rate, long operation cycle, unstable composition of potassium-rich liquid, etc., and achieve low cost, stable composition, and shortened operation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

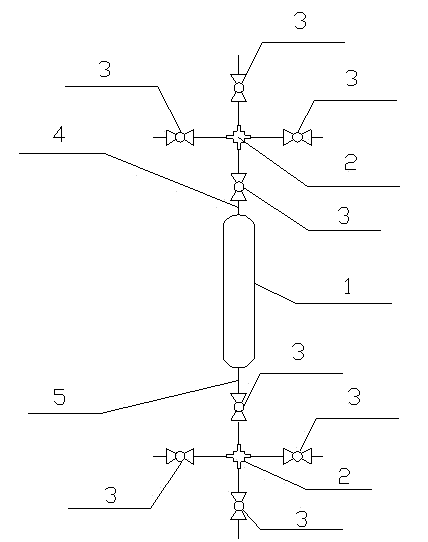

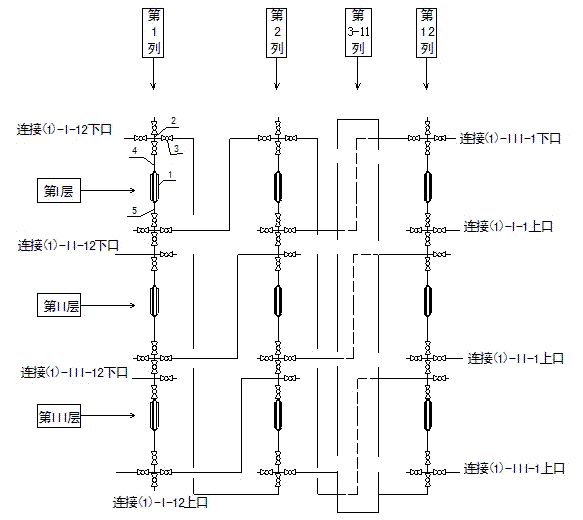

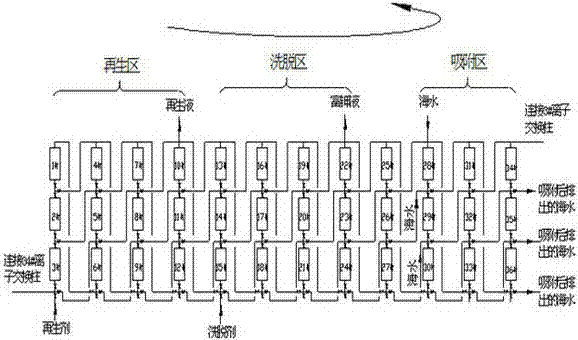

[0032] The first step, simulate the setup of the moving bed

[0033] Complete the setting of the simulated moving bed as mentioned above, the whole continuous ion exchange device is divided into adsorption zone, elution zone and regeneration zone, wherein, in the adsorption zone, an adsorption unit is formed by 6 ion exchange columns 1 connected in series, so that each adsorption unit The mass transfer height is controlled to 6m, including three adsorption units, forming 3 columns; the elution area is composed of 3 columns in series, a total of 9 adsorbed and saturated ion exchange columns 1, and the mass transfer height is 9m during the elution process; the elution is completed The ion exchange column 1 of the process forms the regeneration area, and the regeneration area is composed of 3 columns in series with a total of 9 eluted ion exchange columns 1, and the mass transfer height of the regeneration process is 9m;

[0034] The second step, the adsorption process

[0035] ...

Embodiment 2

[0044] The first step, simulate the setup of the moving bed

[0045] Complete the setup of the simulated moving bed as described above, the above-mentioned whole continuous ion exchange device is divided into an adsorption zone, an elution zone and a regeneration zone, wherein, each layer in the adsorption zone is composed of three ion exchange columns 1 connected in series to form an adsorption unit, so that each The mass transfer height of the adsorption unit is controlled to 3m, including three adsorption units in total, forming 3 columns; the elution area is composed of 2 columns connected in series, a total of 6 adsorbed and saturated ion exchange columns 1, and the mass transfer height during the elution process is 6m; The ion-exchange column 1 that has completed the elution process forms a regeneration zone. The regeneration zone is composed of 4 columns in series and a total of 12 eluted ion-exchange columns 1. The mass transfer height of the regeneration process is 12m...

Embodiment 3

[0056] The first step, simulate the setup of the moving bed

[0057] Complete the setup of the simulated moving bed as described above, the above-mentioned whole continuous ion exchange device is divided into an adsorption zone, an elution zone and a regeneration zone, wherein, each layer in the adsorption zone is composed of five ion exchange columns 1 connected in series to form an adsorption unit, so that each The mass transfer height of the adsorption unit is controlled to 5m, including three adsorption units in total, forming 5 columns; the elution area is composed of 4 columns connected in series, a total of 12 adsorbed and saturated ion exchange columns 1, and the mass transfer height during the elution process is 12m; The ion-exchange column 1 that has completed the elution process forms a regeneration zone. The regeneration zone is composed of 2 columns in series and a total of 6 eluted ion-exchange columns 1. The mass transfer height of the regeneration process is 6m;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com