Unsaturated polyester resin coated controlled-release fertilizer with sulfur as base coating and preparation method thereof

A polyester resin and controlled-release fertilizer technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of high price of coated fertilizers, low sulfur content, and wide application, and achieve good nutrient control Release performance, fast curing and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

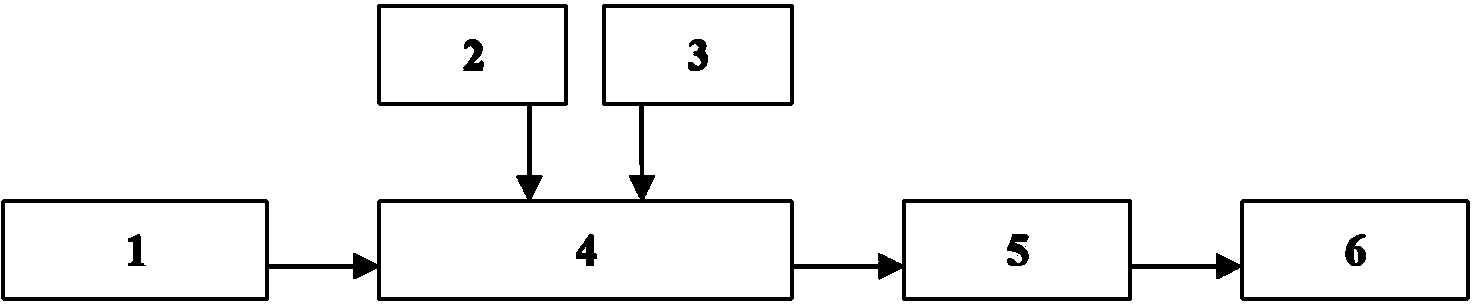

Method used

Image

Examples

Embodiment 1

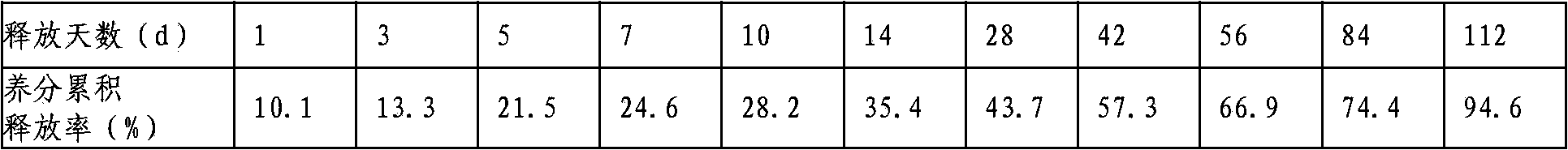

[0023] Put 85kg of large-grain urea with a diameter of 2-5mm into the drum, heat it to 60-90°C, and spray the liquid sulfur heated to the molten state (150-160°C) with compressed air (two-fluid nozzle) On the surface of the urea granule fertilizer, the air atomizing nozzle sprays 15kg of liquid sulfur onto the granule, and the sulfur in the obtained sulfur-coated urea accounts for 15% of the total weight of the fertilizer. Then unsaturated polyester 191#0.288kg, accelerator cobalt octoate 0.006kg and initiator methyl ethyl ketone peroxide 0.01kg are mixed and stirred evenly, then gradually added to the urea granules coated with sulfur, along with the continuous rotation of the drum, that is The unsaturated polyester resin coating solution can be evenly coated on the surface of the particles, and it can be cured into a film in about 5 minutes. The obtained product is an unsaturated polyester resin-coated controlled-release fertilizer with sulfur as the base coat. This fertiliz...

Embodiment 2

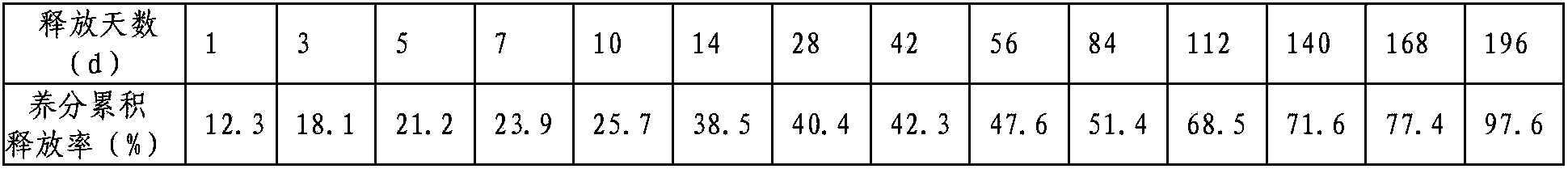

[0027] Put 82kg of large-grain urea with a diameter of 2-5mm into the drum, heat it to 60-90°C, and then spray the liquid sulfur heated to the molten state (150-160°C) with compressed air (two-fluid nozzle) On the surface of urea granule fertilizer, this air atomizing nozzle can spray at a rate of 50-80g per minute, and directly spray all 18kg of liquid sulfur on the granule, and the sulfur in the obtained sulfur-coated urea accounts for 18% of the total weight of the fertilizer . Then unsaturated polyester 3301#0.336kg, accelerator cobalt naphthenate 0.007kg and initiator methyl ethyl ketone peroxide 0.009kg are mixed and stirred evenly, and then gradually added to the sulfur-coated urea particles, with the continuous rotation of the drum , that is, the unsaturated polyester resin coating solution can be evenly coated on the particle surface, and it can be cured into a film in about 5 minutes. This process is repeated twice, and the obtained product is an unsaturated polyest...

Embodiment 3

[0031]Put 80kg of large-grain urea with a diameter of 2-5mm into the drum, heat it to 60-90°C, and spray the liquid sulfur heated to the molten state (150-160°C) with compressed air (two-fluid nozzle) On the surface of urea granule fertilizer, the air atomizing nozzle can spray at a rate of 50-80g per minute, spray 20kg of liquid sulfur onto the granule, and the sulfur in the obtained sulfur-coated urea accounts for 20% of the total weight of the fertilizer. Then unsaturated polyester 3301#0.32kg, accelerator cobalt octoate 0.006kg and initiator cyclohexanone peroxide 0.008kg are mixed and stirred evenly, and then gradually added to the sulfur-coated urea particles, with the continuous rotation of the drum , that is, the unsaturated polyester resin coating solution can be evenly coated on the surface of the particles, and it can be cured into a film in about 5 minutes. This process is repeated three times, and the obtained product is an unsaturated polyester resin-coated contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com