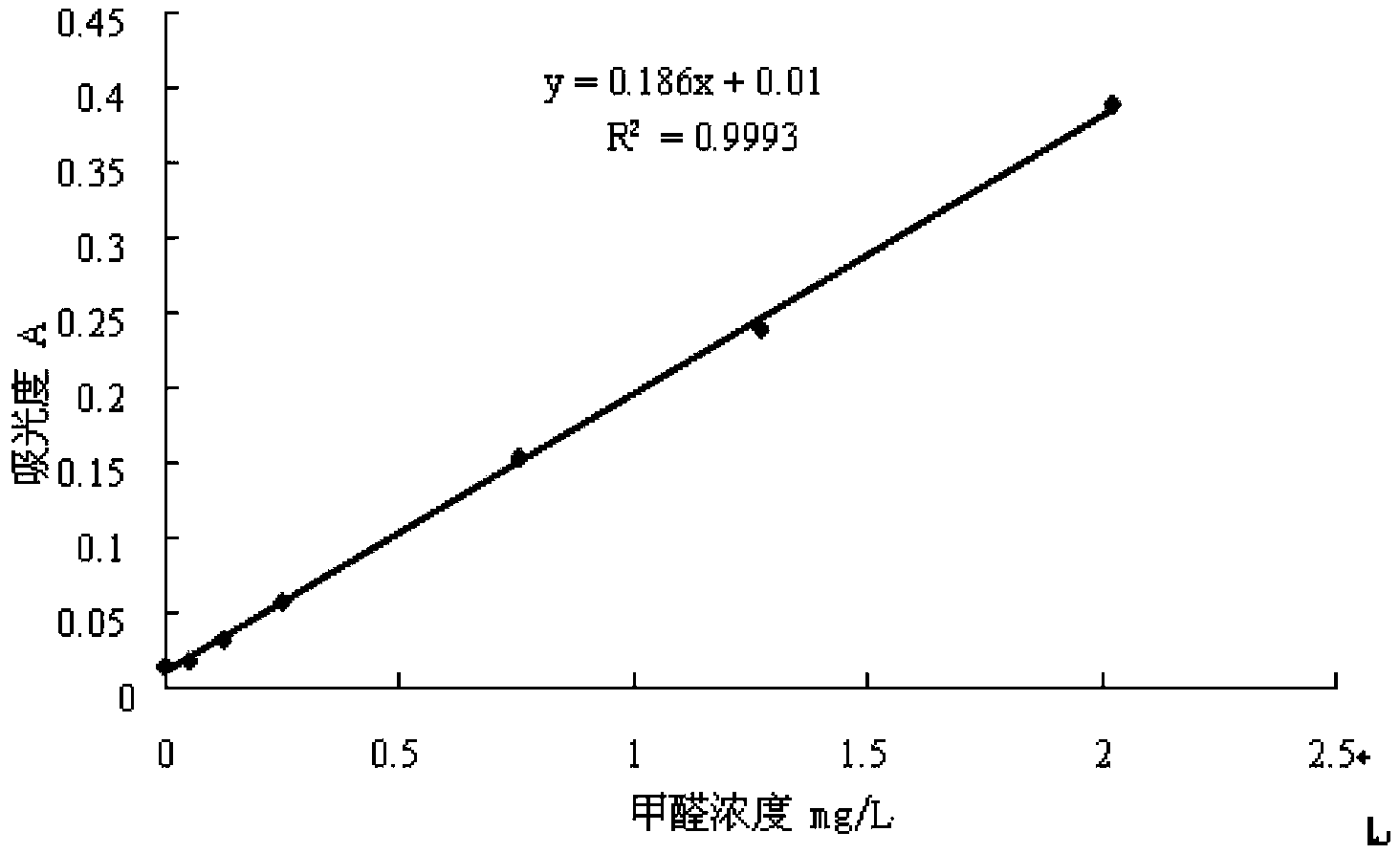

Environmentally friendly water-based paint capable of removing formaldehyde through reacting and preparation method thereof

A water-based paint and formaldehyde technology, which is applied in the field of preparation of environmentally friendly water-based paints, can solve problems such as indoor air pollution, and achieve the effects of simple and easy process, low production cost, and significant reaction and adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of described environment-friendly water-based paint, comprises the following steps:

[0023] Step 1: Add 0.1-0.3 parts by weight of wetting agent, 0.2-0.4 parts by weight of dispersant, and 0.1-0.3 parts by weight of defoaming agent to distilled water in sequence, and then add 20-40 part of the filler, then stirred at high speed to obtain a uniformly dispersed slurry, and finally the slurry was ground by a grinder until the solid particles in the slurry had a fineness of 30-50um, then filtered and set aside;

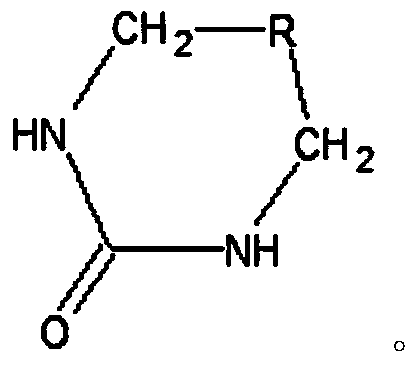

[0024] Step 2: under stirring, gradually add 1-10 parts by weight of ethyleneiminone into distilled water to form an ethyleneiminone solution with a mass fraction of 30%, and then filter to remove insoluble impurities;

[0025] Step 3: Slowly add the ethyleneimine ketone solution obtained in Step 2 into 30-45 parts by weight of the polymer emulsion under stirring, and continue stirring for 20 minutes at a rate of 30 rpm;

[0026] Step 4: To...

Embodiment 1

[0031] The formulation of environmentally friendly water-based paint:

[0032] The ethylene imino ketone of 1 weight part, the styrene-acrylate copolymer emulsion of 45 weight parts, the Eastman Texanol film-forming aid of 2 weight parts, the Hemingsi Dapro DF7015 defoamer of 0.1 weight part, 20 The titanium dioxide of parts by weight, the distilled water of 15 parts by weight, the wetting agent of 0.1 parts by weight, the dispersant of 0.2 parts by weight, the antifungal agent of 0.3 parts by weight, the leveling agent of 0.5 parts by weight, the thickener of 1.5 parts by weight and 2 parts by weight of antifreeze; the pH value of the environmental protection water-based paint is 8.0.

[0033] Prepare each component according to above-mentioned formula, the environment-friendly water-based coating of above-mentioned formula can be prepared by following method:

[0034] Step 1: Add wetting agent, dispersant, and a part of defoamer to distilled water in sequence under low-spee...

Embodiment 2

[0039] This part differs from Embodiment 1 in that:

[0040] The formulation of environmentally friendly water-based paint:

[0041]10 parts by weight of ethylene iminoketone, 30 parts by weight of pure acrylate copolymer emulsion, 0.5 parts by weight of Eastman Texanol film-forming aid, 0.5 parts by weight of Elementis Dapro DF7015 defoamer, 40 parts by weight Calcite, 30 parts by weight of distilled water, 0.3 parts by weight of wetting agent, 0.4 parts by weight of dispersant, 0.1 parts by weight of antifungal agent, 0.1 parts by weight of leveling agent, 0.5 parts by weight of thickener and 1 part by weight The antifreeze agent of part; The pH value of described environmental protection water-based paint is 9.5.

[0042] Step 4: Adjust the pH value to 9.5 with sodium bicarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com