Method for preparing steviol by carrying out catalytic hydrolysis on stevioside by beta-glucosidase

A technology of glucosidase and catalytic hydrolysis, applied in the field of biosynthesis of organic compounds, can solve problems such as poor thermal stability, and achieve the effects of reducing thermal inactivation, taking into account the speed of hydrolysis reaction and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Disperse 15 g St (commercially available, 97% pure) in 55 o C in 100 mL deionized water, put in 55 o Shake in C water bath shaker for 0.5 h, the shaker speed is 150 rpm; add β - Glucosidase enzyme solution 800 U / g St; react until the conversion rate of St no longer rises. St conversion was 99.0%. After cooling the reaction solution, filter it with suction, wash the filter cake with mother liquor and deionized water respectively, and recrystallize with 20% methanol aqueous solution to obtain the steviol product. The HPLC purity of the final product was greater than 98%. The reaction required a total of 8 hours.

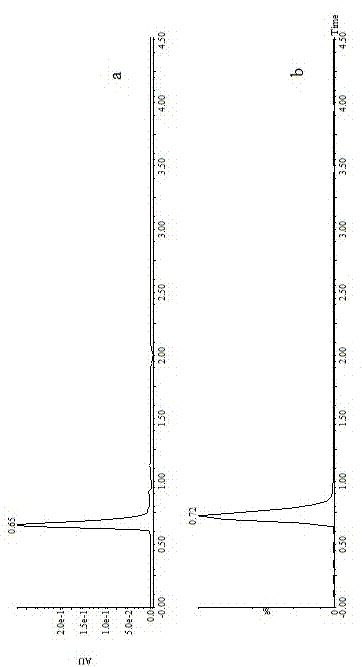

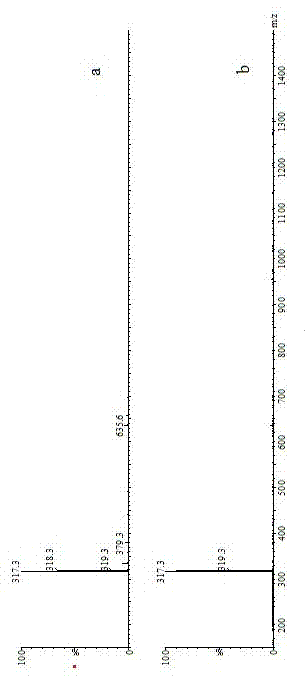

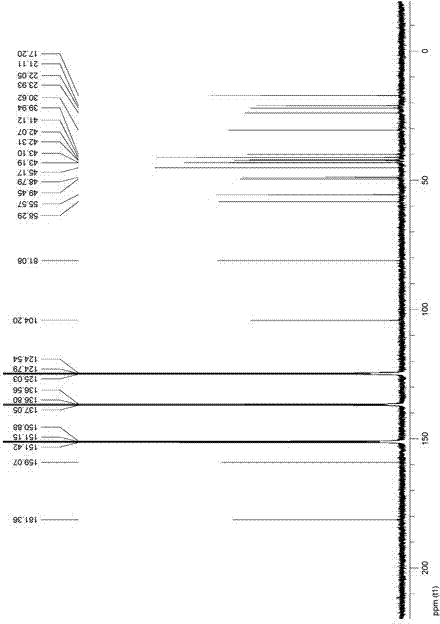

[0019] The product is analyzed by LC-MSMS and NMR, the results are shown in the attached Figure 1-3 . The molecular ion peak of the main component in LC-MSMS (317.4, [M-H] - ) can correspond to steviol, and the NMR of the hydrolyzate can further confirm that the product is steviol.

[0020] The conversion rate of St can be determined by the HPLC externa...

Embodiment 2

[0026] Dissolve 20 g of 90% St (stevia extract, containing 10% RA) in 55 o C in 100 mL deionized water, put in 55 o Shake in C water bath shaker for 0.5 h, the shaker speed is 150 rpm; add β -Glucosidase enzyme solution 600 U / g St; rise to 75 after 3 h reaction o C continues to react until the conversion rate of St no longer increases. Then recrystallize with 20% methanol aqueous solution to obtain steviol product. The reaction required a total of 3.5 hours.

Embodiment 3

[0028] Disperse 15 g St in 50 mM 100 mL pH 5.0 acetate buffer in 55 o Shake in C water bath shaker for 0.5 h, the shaker speed is 150 rpm; add β - Glucosidase enzyme solution 700 U / g St; rise to 70 after 3h reaction o C continues to react until the conversion rate of St no longer increases. The reaction takes 4 hours in total. Then recrystallize with 20% methanol aqueous solution to obtain steviol product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com