Preparation method of acetone steam gas-sensitive sensing element based on zinc oxide film

A zinc oxide film, acetone vapor technology, applied in vacuum evaporation plating, ion implantation plating, coating and other directions, can solve the problem of not being able to detect the presence or absence of acetone and its concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

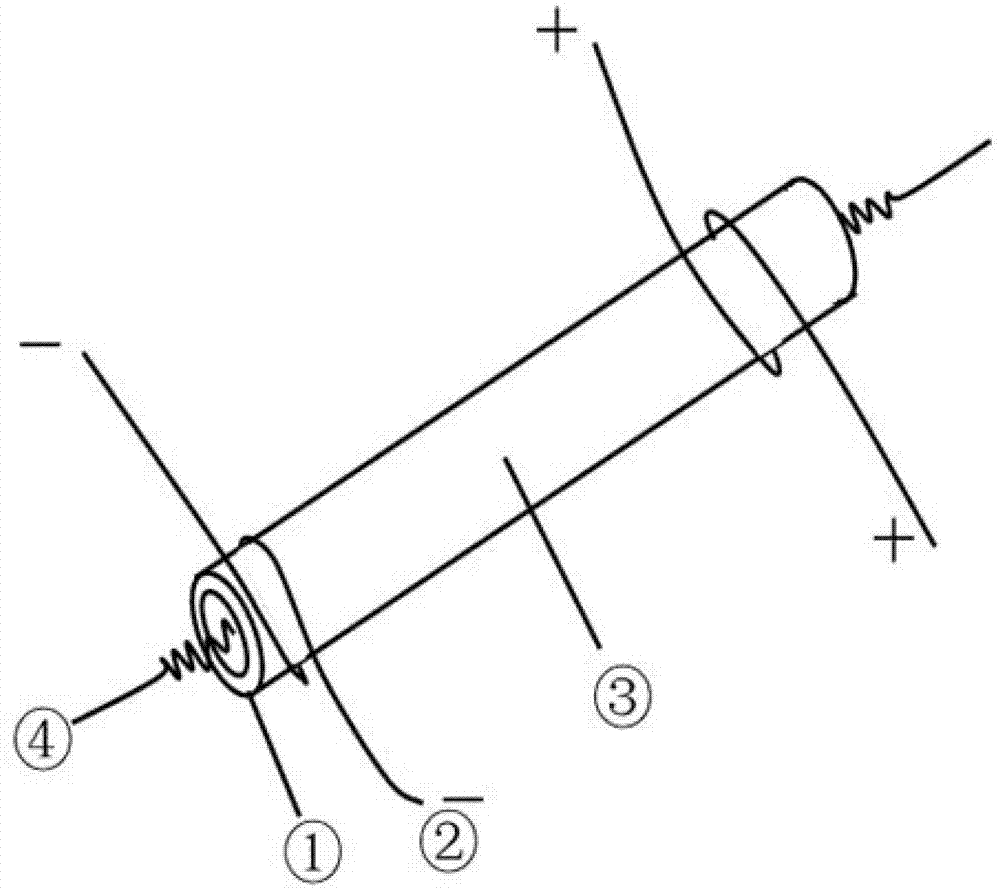

[0020] RF sputtering ZnO film

[0021] The Zn0 film is deposited on the outer surface of the ceramic tube by radio frequency magnetron sputtering. Before the experiment, clean the ceramic tube with alcohol. The target material of RF magnetron sputtering is Zn0, and the distance between the target and the substrate is about 40mm. During the reactive deposition process, argon (Ar) is used as sputtering gas, oxygen (0 2 ) Is the reaction gas.

[0022] The Zn0 film was prepared on the FJL560 ultra-high vacuum magnetron sputtering apparatus. The Zn0 film prepared on RF magnetron sputtering equipment and the test process are as follows:

[0023] (1) Put a Zn target with a purity of 99.99% on the DC sputtering target, install the cleaned ceramic tube on the instrument slide, and close the vacuum chamber;

[0024] (2) Pump the system to vacuum before sputtering. The process is as follows: start the mechanical pump, and the mechanical pump pumps the magnetron sputtering chamber. When the po...

Embodiment 2

[0034] (1) Put a Zn target with a purity of 99.99% on the DC sputtering target, put the cleaned ceramic tube on the sample holder, and close the vacuum chamber;

[0035] (2) Pump the system to vacuum before sputtering. The process is as follows: start the mechanical pump, and the mechanical pump pumps the magnetron sputtering chamber. When the pointer of the vacuum gauge reaches 1-30Pa, start the molecular pump and use the molecular pump to Control the sputtering chamber to vacuum until the system pressure reaches 1×10 -3 5pa;

[0036] (3) After vacuuming, open the gas circuit valves of oxygen and argon, and pass these two gases into the system. 2 : Ar=1:2, make the pressure in the system reach 0.5pa;

[0037] (4) After the gas is introduced, heat the ceramic tube slide to a temperature of 250°C;

[0038] (5) Finally start sputtering: the voltage between the Zn target and the slide is 400V, and the sputtering current is 0.3A. At first, it needs to pre-sputter for about 8 minutes, and...

Embodiment 3

[0041] (1) Put a Zn target with a purity of 99.99% on the DC sputtering target, and remove the cleaned Al 2 O 3 Place the ceramic tube on the sample holder and close the vacuum chamber;

[0042] (2) Pump the system to vacuum before sputtering. The process is as follows: start the mechanical pump, and the mechanical pump pumps the magnetron sputtering chamber. When the pointer of the vacuum gauge reaches 1-30Pa, start the molecular pump and use the molecular pump to Control the sputtering chamber to vacuum until the system pressure reaches 5×10 -3 pa;

[0043] (3) After vacuuming, open the gas circuit valves of oxygen and argon, and pass these two gases into the system. 2 : Ar=1:2, make the pressure in the system reach 0.8pa;

[0044] (4) After the gas is introduced, heat the ceramic tube slide to a temperature of 250°C;

[0045] (5) Finally start sputtering: the voltage between the Zn target and the slide is 350V, and the sputtering current is 0.2A. At first, it needs to pre-sputter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com