Coal ash and ash combined re-circulating system for preventing boiler from being polluted

A recirculation system, fly ash technology, applied in lighting and heating equipment, chemical instruments and methods, solid fuel combustion, etc. Insufficient and other problems to achieve the effect of increasing operating time, reducing pressure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

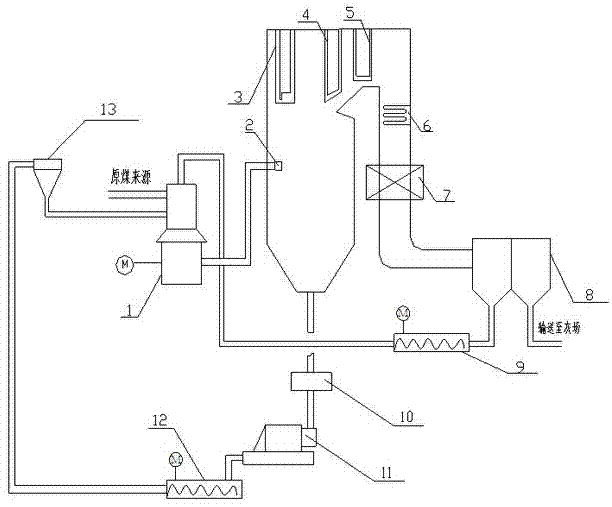

[0029] Such as figure 1 As shown, a combined recirculation system of fly ash and ash to prevent boiler contamination, including a fly ash recirculation system and ash recirculation system, wherein:

[0030]The fly ash recirculation system includes a coal mill 1 and a dust collector 8, the discharge port of the coal mill 1 is connected to the boiler burner 2, the feed port of the dust collector 8 is connected to the air preheater 7 of the tail flue of the boiler Outlet connection; the dust collector 8 is provided with two outlets, one for outputting the coal ash outlet, one for returning the coal ash outlet, and the return coal ash outlet is connected to the feed port of the coal mill 1;

[0031] The ash recycling system includes a coal mill 1, an ash storage bin 13, an ash crusher 11, and an ash dryer 10. The outlet of the coal mill 1 is connected to the burner 2 of the boiler, and the ash dryer 10 The feed port of the boiler is connected with the outlet of the slag pool of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com